Backlight module set and its light guide plate

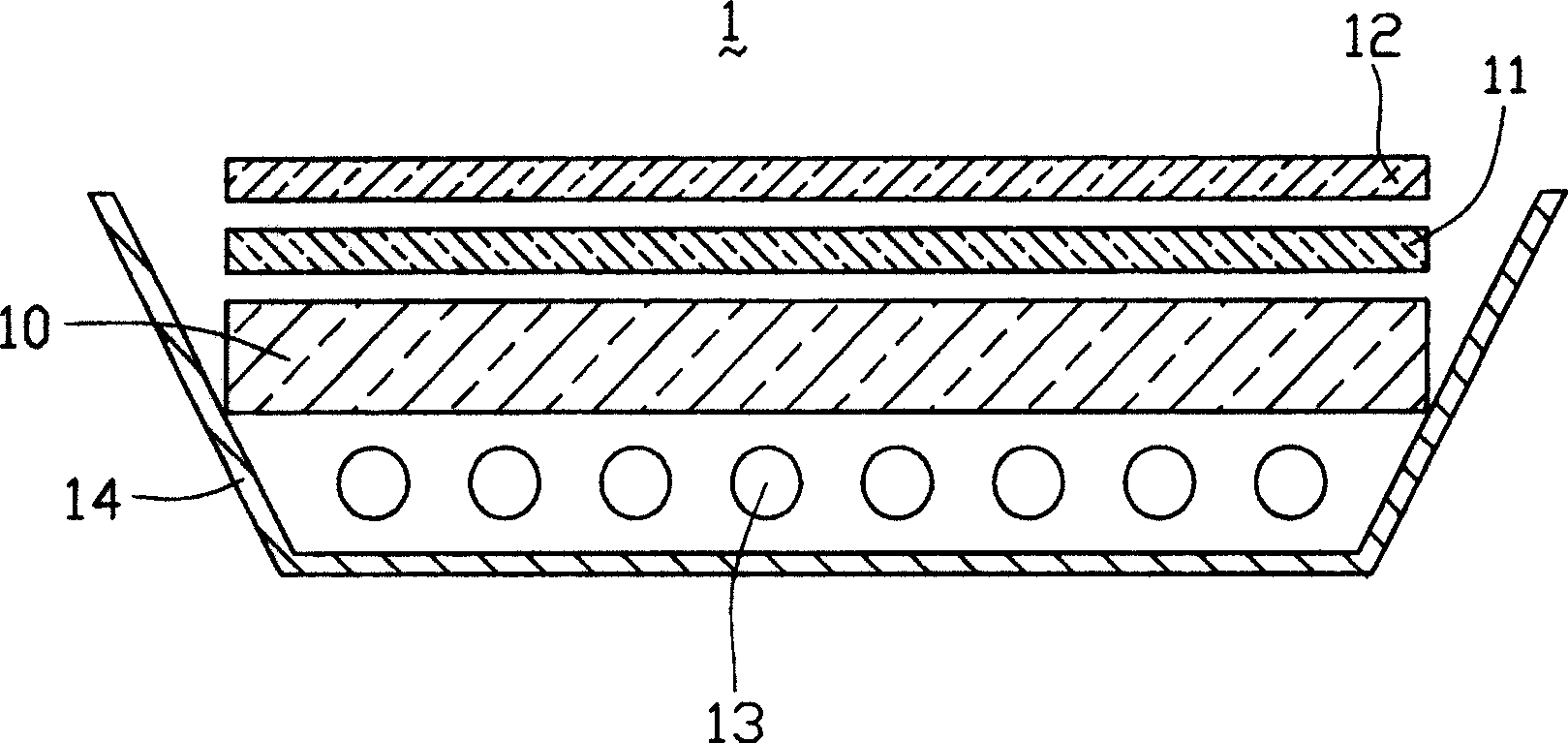

A backlight module and light guide plate technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as consumption of light utilization, underutilization of light, uneven light output from backlight module 1, etc., to avoid excessive light intensity High, light utilization rate increased, the effect of uniform output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

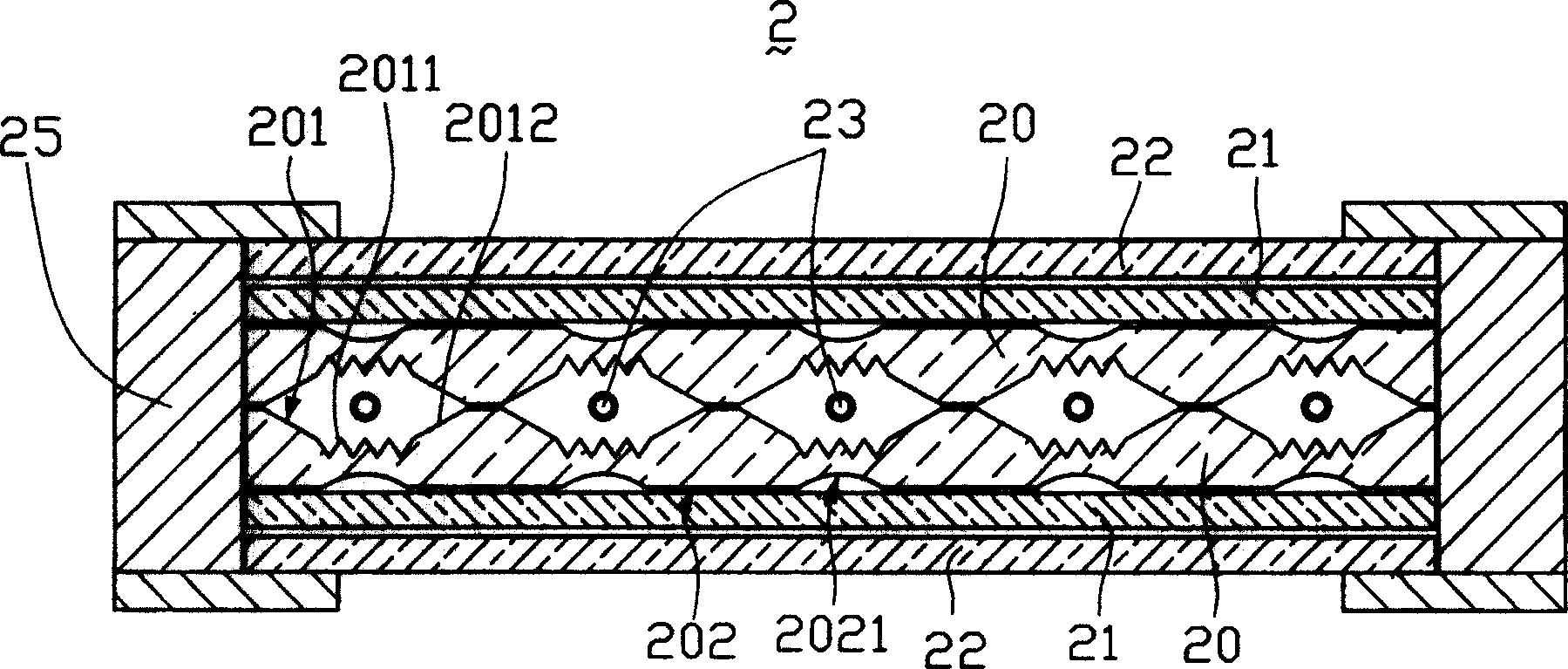

[0031] see figure 2 , is an embodiment of the backlight module of the present invention. The backlight module 2 includes two light guide plates 20 , a plurality of lamp tubes 23 , two prism sheets 21 , two diffusion sheets 22 and an outer frame 25 .

[0032] The lamp tubes 23 are generally cold cathode fluorescent lamps, and several lamp tubes 23 are arranged in parallel in the backlight module 2 .

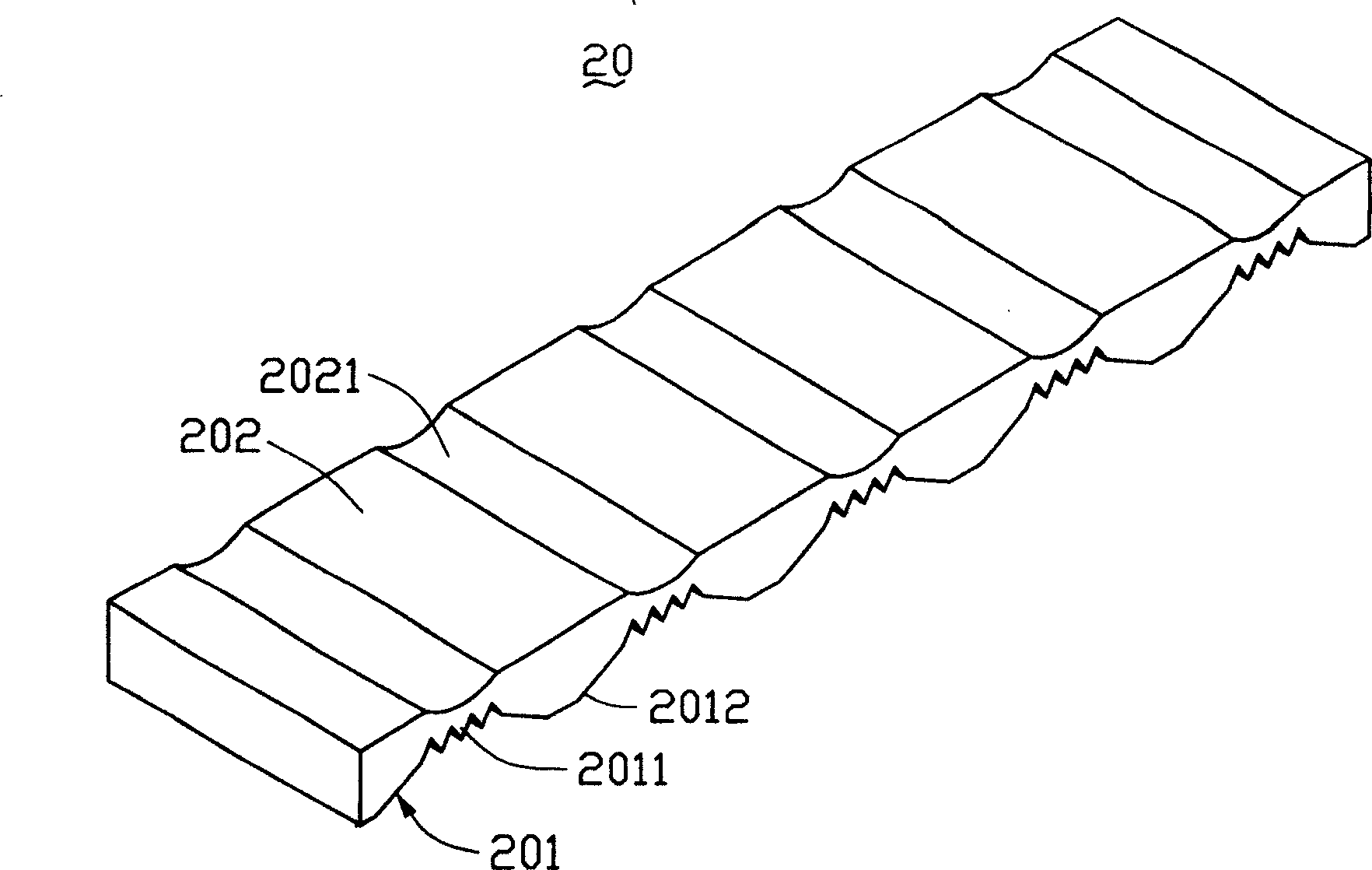

[0033] The two light guide plates 20 are arranged symmetrically with the plane formed by a plurality of lamp tubes 23 arranged in parallel as the symmetrical plane, and respectively include a light incident surface 201 and a light exit surface 202 opposite to the light incident surface 201, and only one of them will be described below. . The light incident surface 201 of the light guide plate 20 includes a plurality of first protrusion groups 2011 arranged at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com