Remote monitoring predicting method of empty zone hard top plate

A technology of hard roof and goaf, which is applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve the problems that the roof is difficult to determine the wave peak value, caving, and there is no large-scale roof in goaf, so as to avoid errors and Other artificially inaccurate data, the effect of reliable monitoring data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

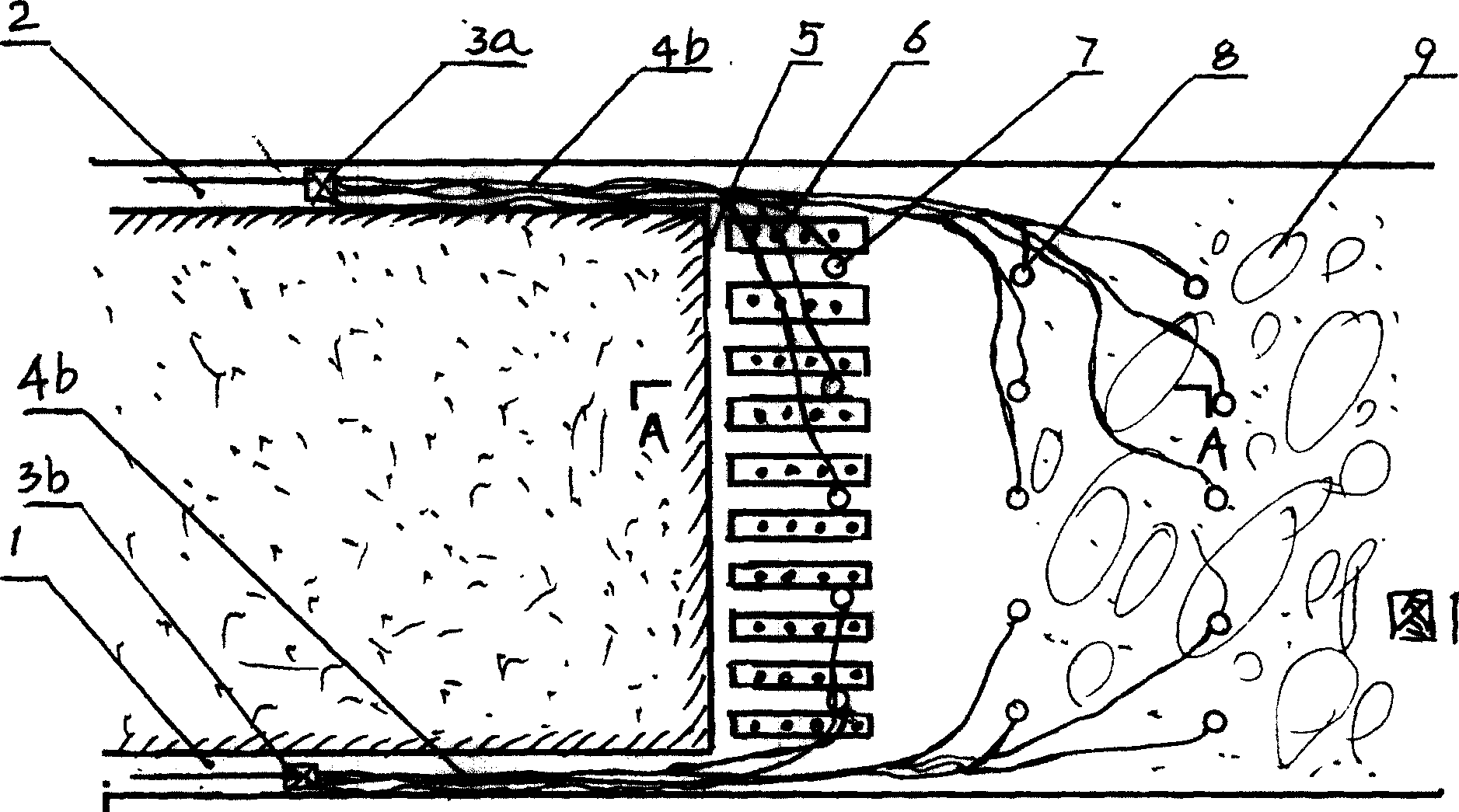

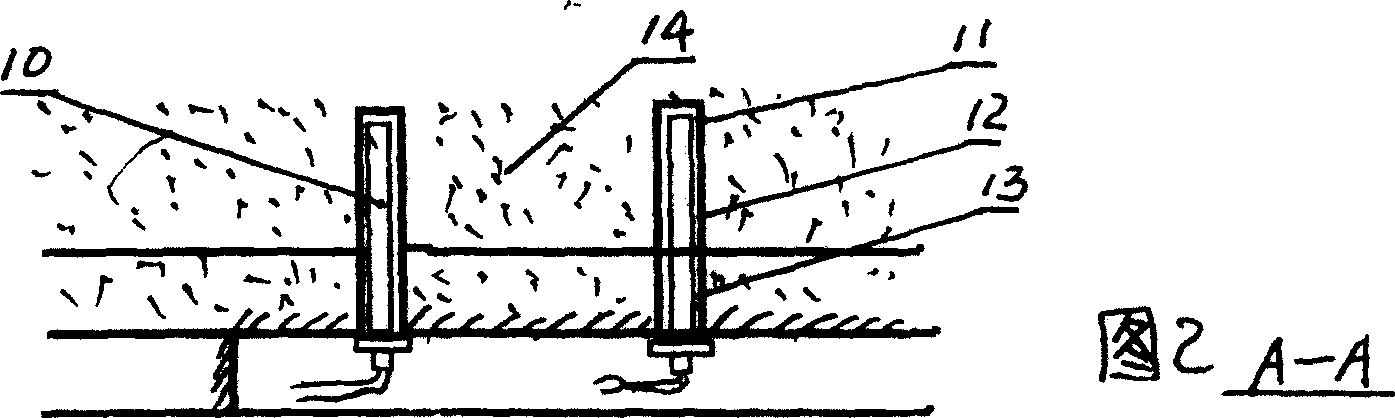

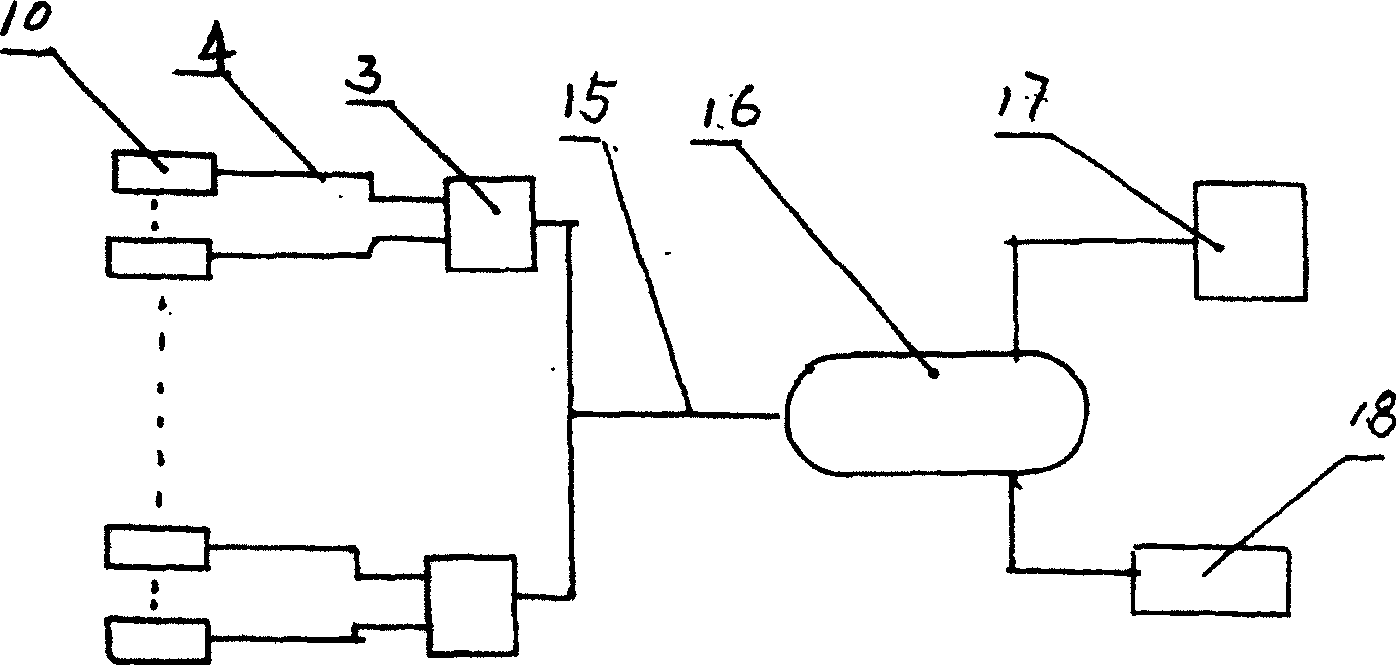

[0022] 1. As shown in Figure 1, along with the mining of the coal seam 5 in the working face, a row of boreholes 7 are drilled on the roof 14 at intervals of 20 meters along the inclination direction of the working face 5 near the rear row of pillars of the working face 5. The depth of the hole exceeds the thickness of the hard top plate, and as shown in Figure 2, a separation layer sensor 10 is installed. The four sensing points of the separation layer sensor 10 are distributed at the bottom reference point 11, the deep part 12 measuring point, the shallow part measuring point 13 and the hole bottom reference point 11. On the surface of the mouth, the positions of the deep measuring point 12 and the shallow measuring point 13 are determined according to the difference in stratification of the roof strata.

[0023] Every 20 meters that the working face 5 advance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com