Fixative for in situ harnessing heavy metal pollution of soil

An in-situ treatment and heavy metal technology, applied in the field of in-situ remediation of polluted soil, can solve the problems of poor treatment effect of pollution phenomenon, inability to replenish soil nutrients in time, single component of fixative, etc., and achieve stable and reliable preparation process and passivation. Mobility, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Naturally burned corn stalk ash is manually sorted to remove residues such as gravel and mixed in a weight ratio of 2:1 (NH 4 ) 2 HPO 4 , according to 2:1 water and soil (lye and straw ash+(NH 4 ) 2 HPO 4 ) weight ratio by adding 0.1M NaOH, its pH = 7.54, stirring for 24 hours, then heat-treating at 90°C to balance, crushing and passing through a 2mm sieve for later use.

[0022] Batch experiment: (detection parameters)

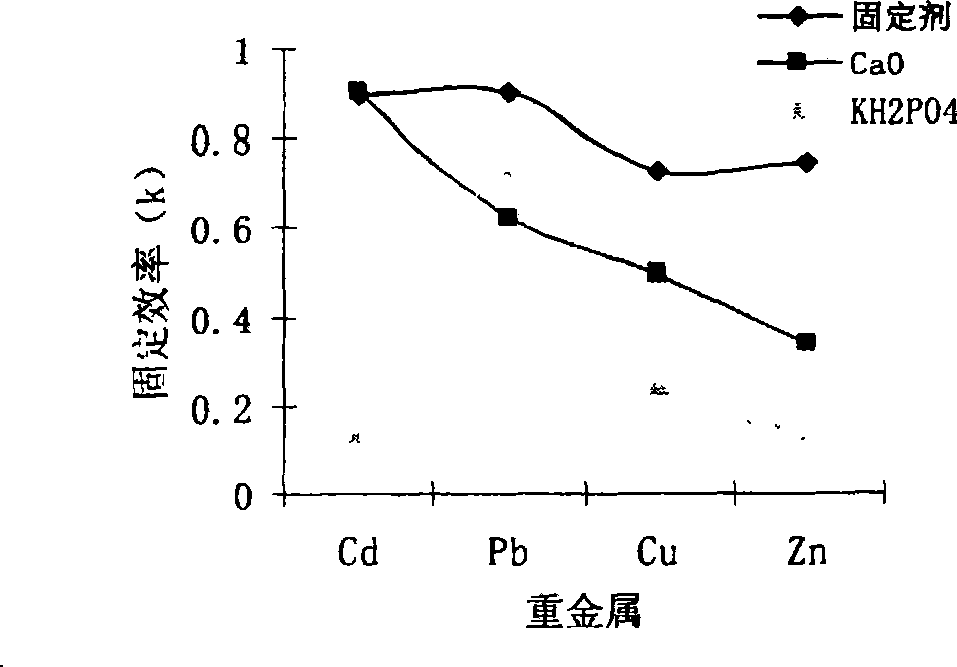

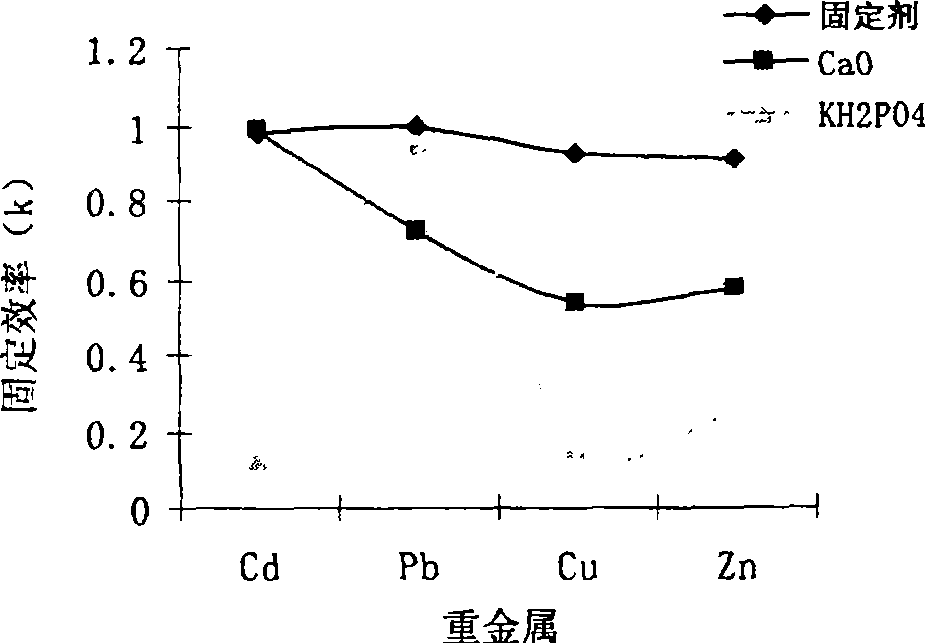

[0023] 1) Adsorption experiment: 50ml of 100ppm cadmium, 1500ppm lead, 2000ppm copper and 2000ppm zinc solution was mixed and oscillated with 1g of different fixed substances for 24 hours, and the adsorption capacity of different substances was determined by measuring the concentration of heavy metal ions in the solution. For the results, see figure 1 Shown, wherein fixative is the fixative product that the embodiment of the present invention 1 makes. Calculated as follows:

[0024] K = 1 - ...

Embodiment 2

[0030] The wheat straw ash of natural incineration is manually sorted to remove residues such as gravel, and mixed in a weight ratio of 5:1 (NH 4 ) 2 HPO 4 , according to the water and soil of 2.5:1 (lye and straw ash+(NH 4 ) 2 HPO 4 ) weight ratio by adding 0.5M Ca(OH) 2 , its pH=8.13, after stirring for 4 hours, it was heat-treated at 80°C to balance, crushed and passed through a 4mm sieve for later use.

Embodiment 3

[0032] The rice straw ash of natural incineration is manually sorted to remove residues such as gravel and the like, and mixed in a weight ratio of 4:1 (NH 4 ) 2 HPO 4 , according to the water and soil of 3:1 (lye and straw ash+(NH 4 ) 2 HPO 4 ) weight ratio by adding 0.05M KOH, its pH = 8.25, stirring for 12 hours and then heat-treating at 98°C to balance, crushing and passing through a 3mm sieve for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com