Two-section lens driver

A lens driving device, a two-stage technology, applied in installation, optics, instruments, etc., can solve problems such as undisclosed technical features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

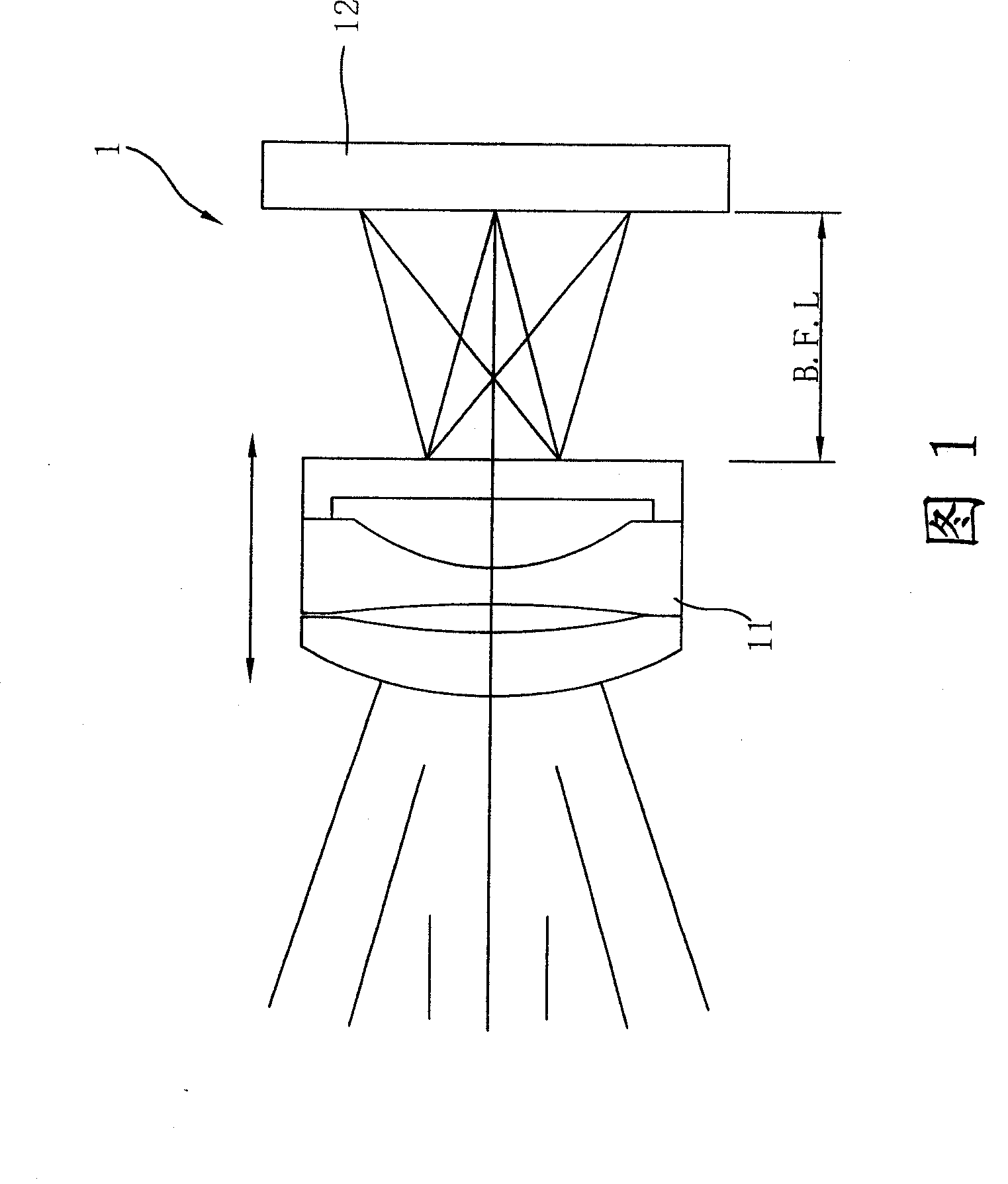

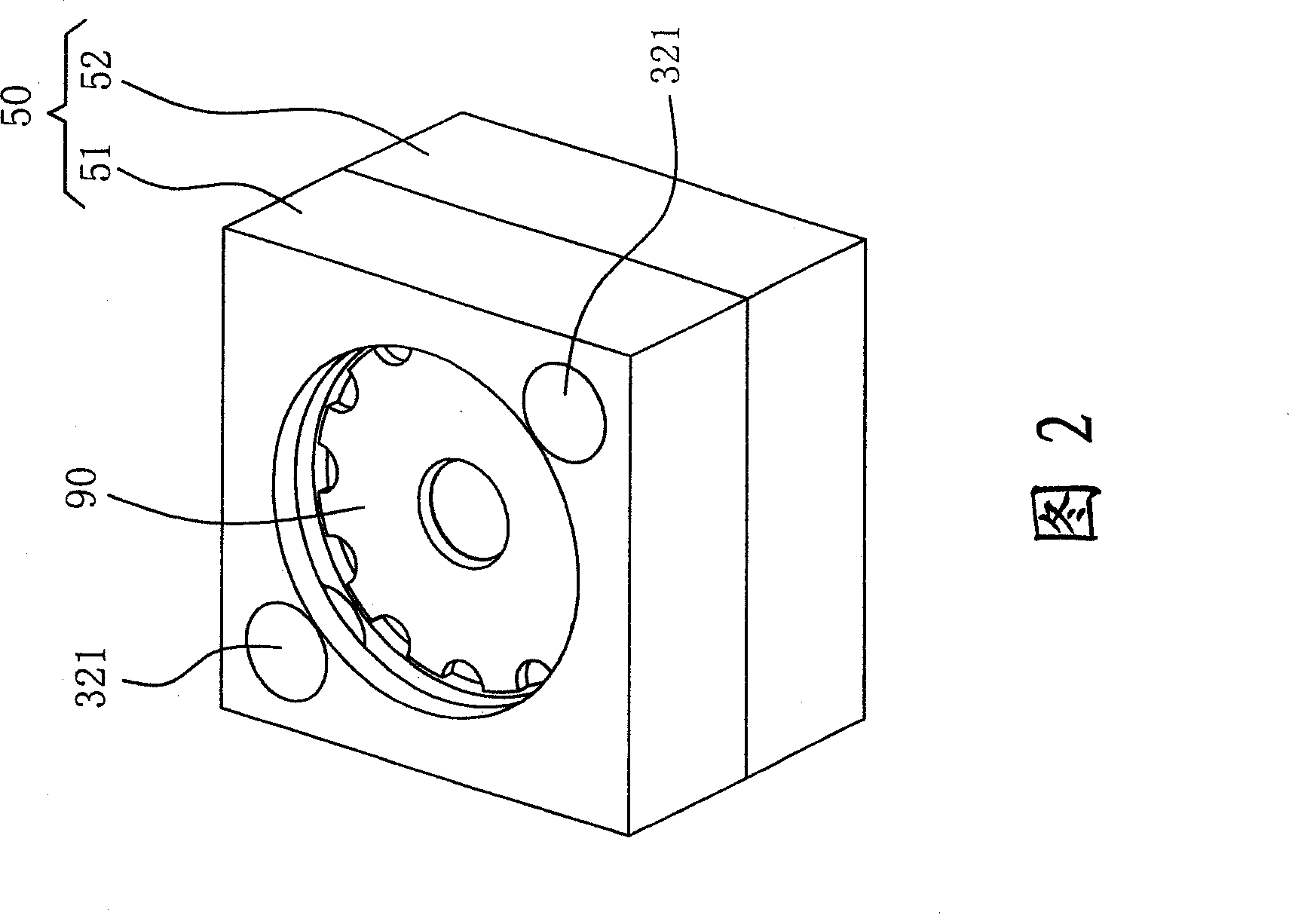

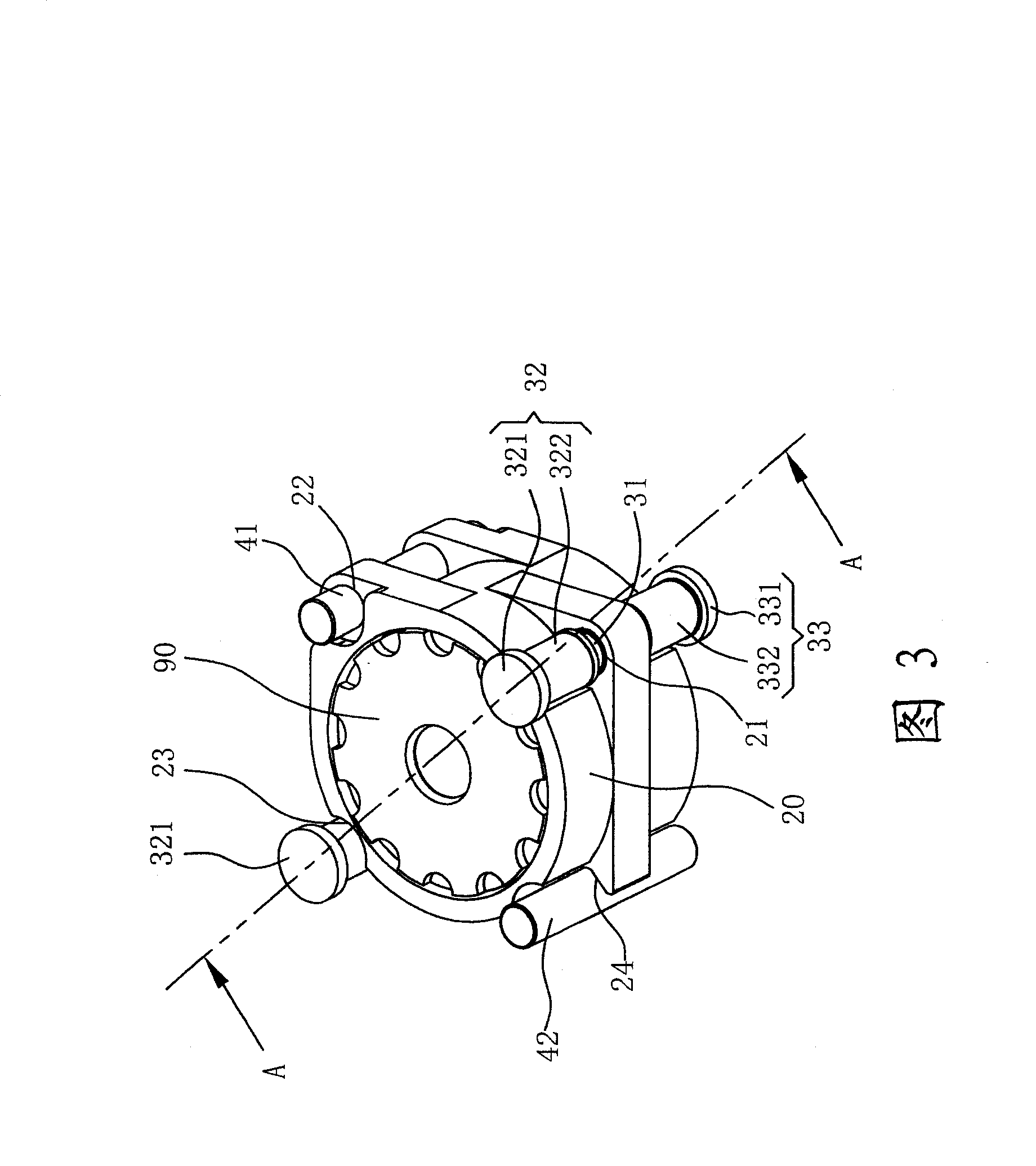

[0035] Please refer to FIG. 2 to FIG. 4B , which disclose a first preferred embodiment of the two-stage lens driving device of the present invention. Wherein, FIG. 2 is a three-dimensional combined view of the first preferred embodiment of the two-stage lens driving device of the present invention. FIG. 3 is a three-dimensional assembly view of the first preferred embodiment of the two-stage lens driving device of the present invention after the housing is removed. 4A is an A-A cross-sectional view of the two-stage lens driving device of the present invention as shown in FIG. 2 , when the lens carrying seat is in the first position. 4B is an A-A cross-sectional view of the two-stage lens driving device of the present invention as shown in FIG. 2 , when the lens carrying seat is in the second position.

[0036] As shown in Fig. 2, Fig. 3, Fig. 4A and Fig. 4B, in the first preferred embodiment of the present invention, the two-stage lens driving device includes: a A lens holde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com