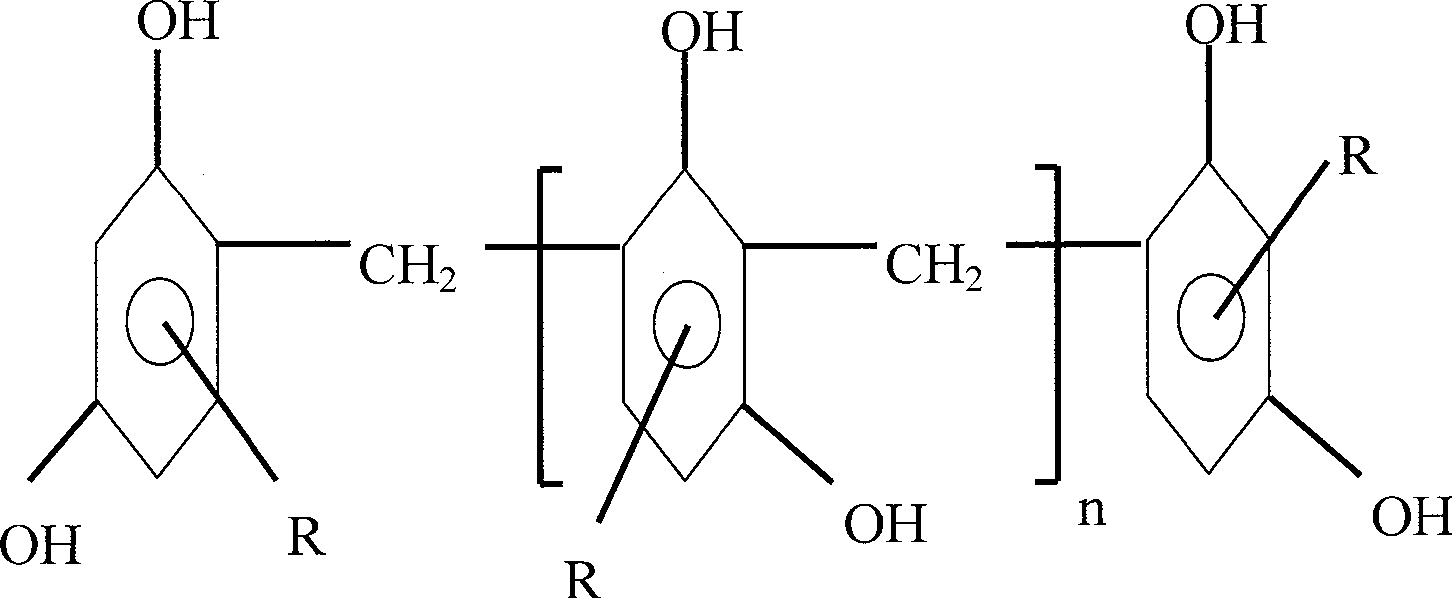

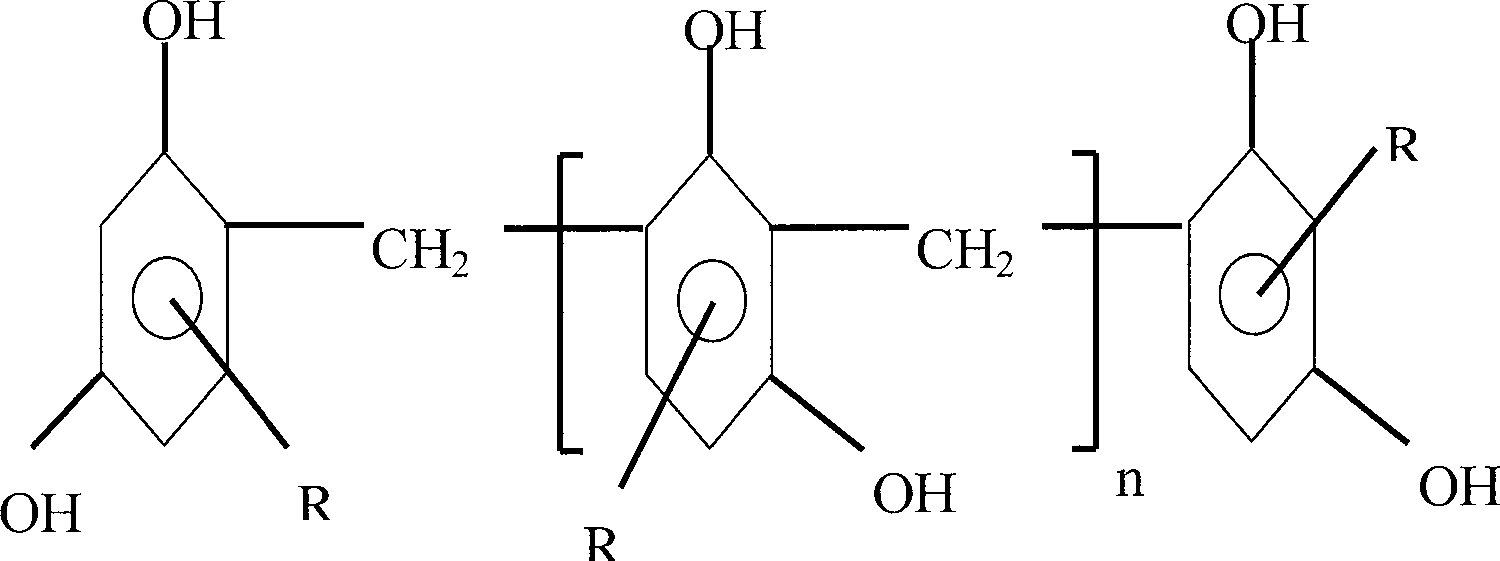

Alkyl resorcinol formaldehyde resin and its production process

An alkyl resorcinol formaldehyde resin and production process technology, applied in the field of chemical production raw materials, can solve the problems of irritating smog, polluting the environment, frosting, etc., achieve the effect of no frosting and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Example 1: Add 250g of resorcinol to a 500ml reaction bottle, heat up to complete melting, then add 6g of oxalic acid with stirring at about 115°C, and start adding styrene dropwise when the temperature rises to 120-125°C for about 30 minutes After dripping 105g of styrene, keep this temperature for 30 minutes, then start to add 110g of formaldehyde solution dropwise at 100-105°C under stirring, drop it for about 1 hour, then reflux for 30 minutes, then heat up and dehydrate, and the water will be completely removed Then add 25g of styrene and react at 120-125°C for 30 minutes, then neutralize with 20% NaOH aqueous solution to neutralize, distill and dehydrate and remove small molecules, and control the softening point of the product at 90-120°C to be qualified. The softening point of the experimental product is 109°C, the free phenol is 0.6%, and the yield is 385g.

Embodiment 2

[0009] Example 2: In a 500ml reaction bottle, add 250g of resorcinol and 100g of water and heat up to dissolve, add 6.5g of oxalic acid under stirring, when the temperature rises to 90°C, start to add 115g of formaldehyde dropwise, and control the temperature at 90-110°C to complete the dropwise After formaldehyde, heat up to distill and dehydrate. When the room temperature reaches 120°C, start to add styrene dropwise, and control the temperature at 120-130°C to drop 110g of styrene and then react for 30 minutes, add 20% NaOH solution to neutralize , and then distilled to remove water and small molecules, the measured softening point was 103°C, the free phenol was 0.95%, and the yield was 370g.

Embodiment 3

[0010] Example 3: Put 220g of resorcinol into a 500ml reaction bottle and heat it up until it melts, add 6.3g of oxalic acid at 120°C, then add 95g of styrene dropwise at 120-130°C, and react at this temperature for 30 minutes after dropping , when the temperature is lowered to 110°C, drop 100.3g of formaldehyde and react at 100-105°C for 1 hour and 30 minutes, heat up and dehydrate, and when the temperature reaches 125°C, add 22g of styrene dropwise and react at this temperature After 30 minutes, after being neutralized with 20% NaOH, heat up and distill and dehydrate, take a sample to measure the softening point, when the softening point is 115°C, discharge, measure 0.45% of free resorcinol, yield 345g.

[0011] The free resorcinol of alkylresorcinol formaldehyde resin and RF resin is compared as shown in table 1: table 1

[0012] Variety RF resin Embodiment one Embodiment two Embodiment Three free resorcinol

[0013] Therefore, this product is an alkyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com