Clamp for grinding magnetic head, grinding apparatus and grinding method

A technology of a grinding device and a grinding method, applied in the directions of grinding devices, positioning devices, grinding machine tools, etc., can solve problems such as reducing the yield of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

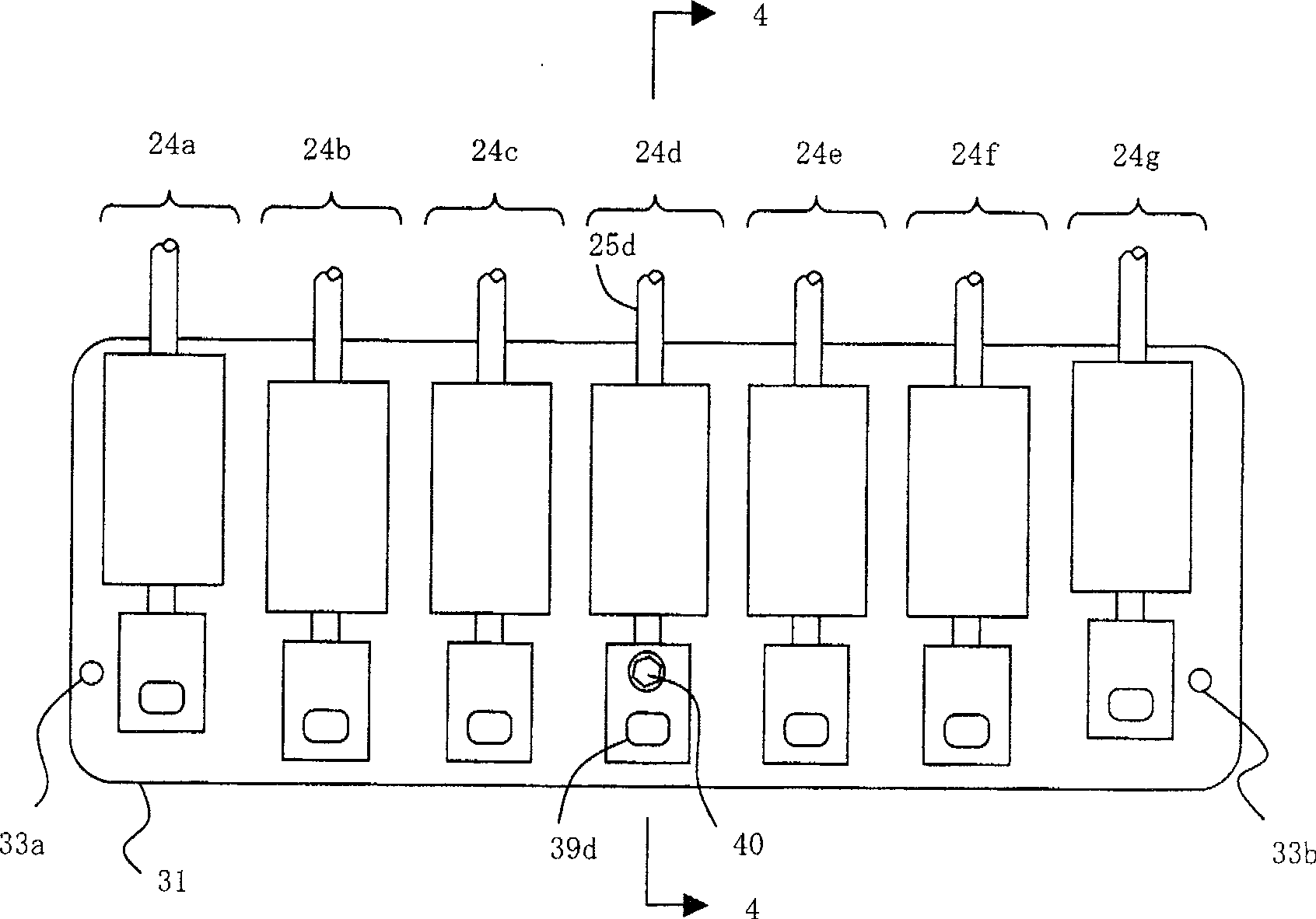

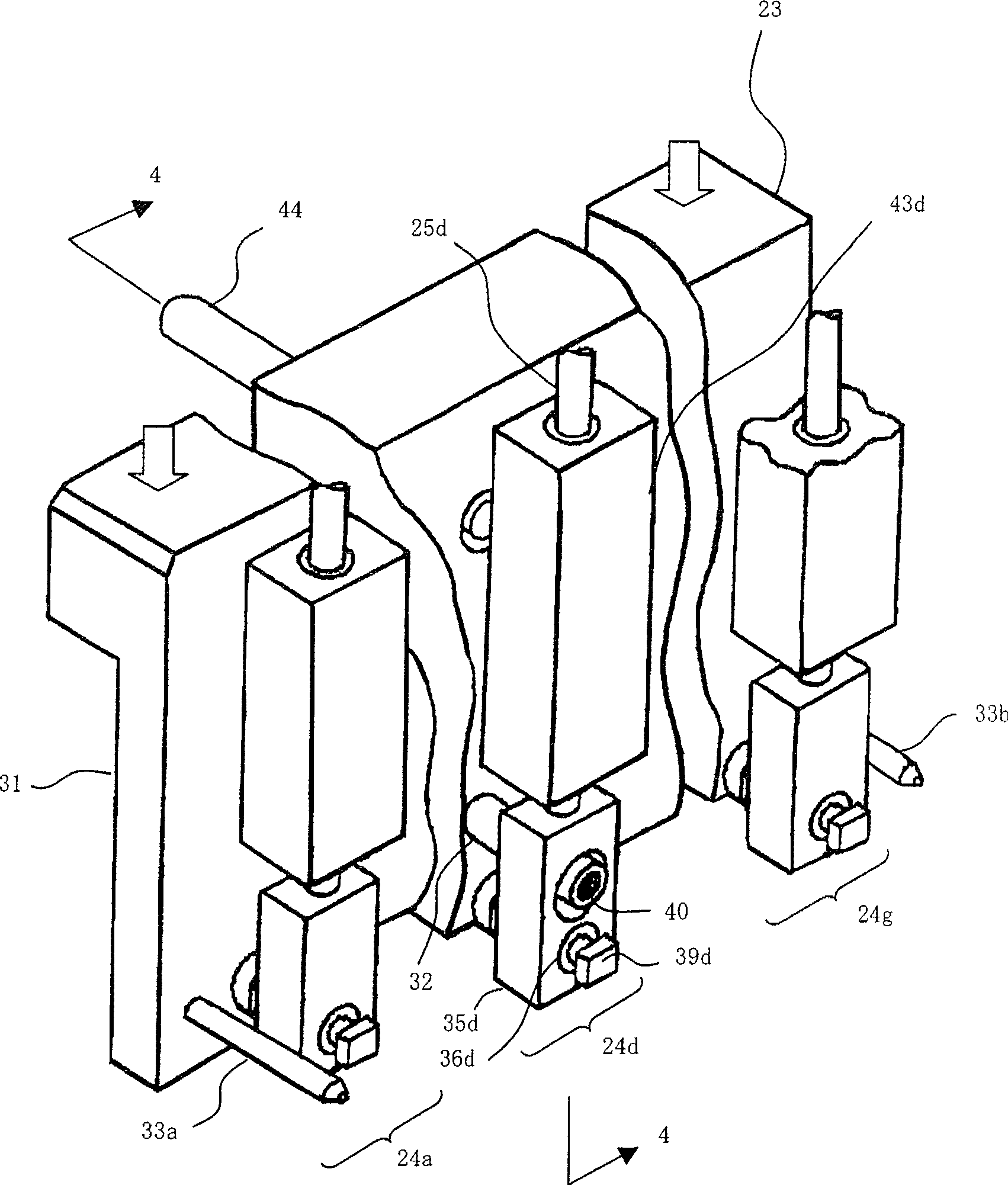

[0066] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

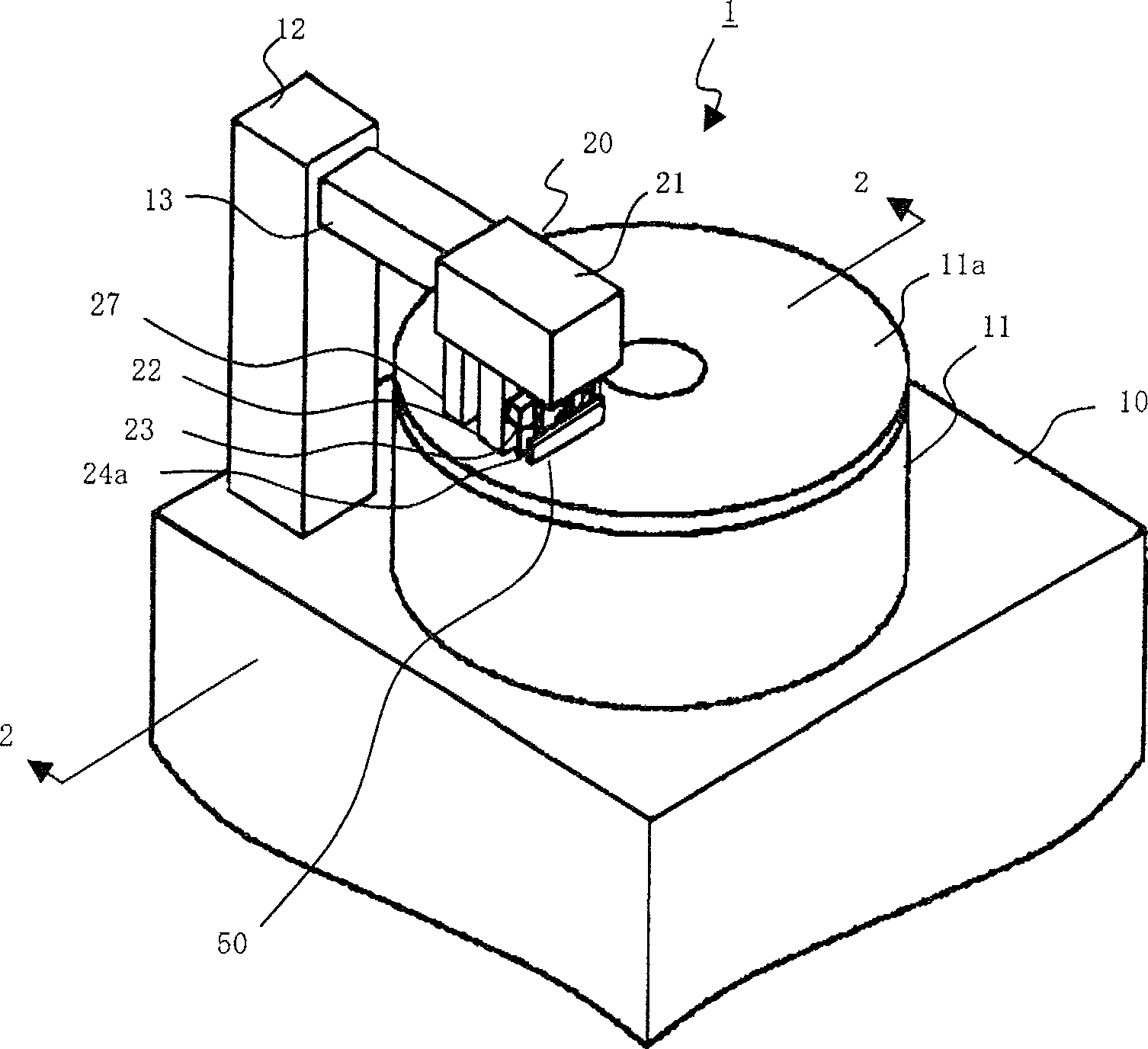

[0067] figure 1 A perspective view showing a schematic structure of a polishing apparatus according to an embodiment of the present invention. The grinding device 1 is used to grind the rod-shaped magnetic head members arranged in a row by the magnetic heads, that is, the elongated bar. Grinding device 1 comprises worktable 10, is located at the rotary grinding table 11 on the working table 10, is located at the pillar 12 of one side of rotary grinding table 11, the arm part 13 that stretches out from pillar 12 to the top of rotating grinding table 11 and installation. The component supporting part 20 of the arm part 13 . Wherein, the rotary grinding table 11 has a grinding surface 11a for grinding the elongated bar.

[0068] The component support part 20 includes a support part body 27 connected to the arm part 13, a part material 22 provided in fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com