Method for polishing and grinding hydrant drill end

A processing method and face grinding technology, applied in metal processing equipment, grinding/polishing equipment, machine tools suitable for grinding workpiece edges, etc., can solve the requirements of low tool life of processing equipment, simple processing steps, and high self-adaptation requirements. and other problems, to achieve the effect of being conducive to quality control and process management, improving processing efficiency, and processing a large number of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for grinding and polishing a rhinestone end face, the steps are as follows:

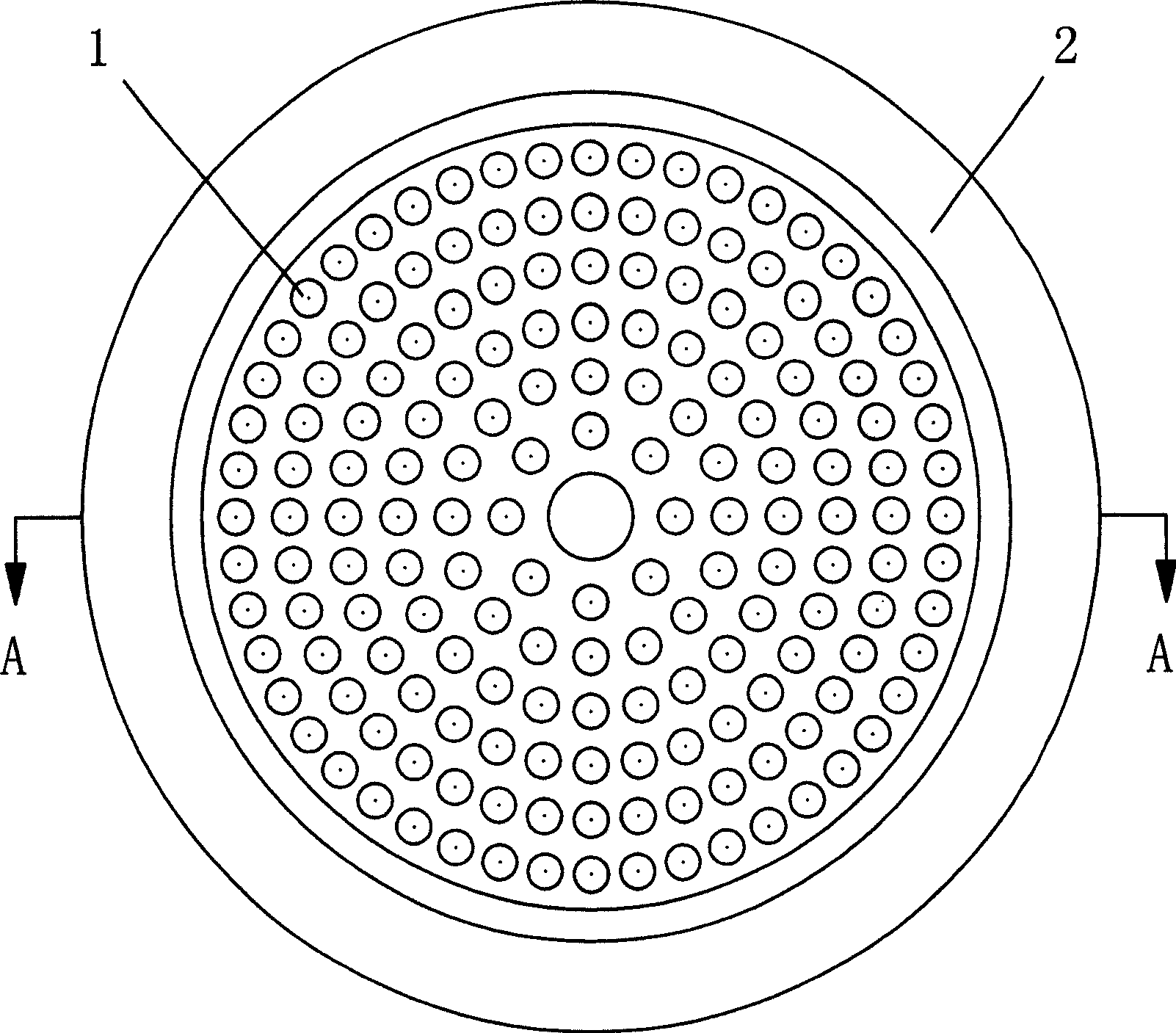

[0047] 1) Fabric, evenly arrange the rhinestones 1, and vertically embed them on the surface of the tooling plate 3;

[0048] 2) Blister forming, the tooling plate 3 embedded with the rhinestone 1 is put into the blister machine, and the blister plate 2 is formed on the surface of the tooling plate 3, the concave surface of the blister plate 2 is upward, and the rhinestone 1 is vertically adsorbed and fixed on the blister On the convex surface of the bottom of disc 2;

[0049] 3) Grinding and polishing of the end face, the concave surface of the blister disc 2 is set on the grinding and polishing machine, and the tip of the rhinestone 1 at the bottom of the blister disc 2 is ground and polished on the flat grinding disc to form the end face;

[0050] 4) Unpacking, the blister tray 2 is put into the unsealing machine, and the rhinestone 1 and the blister tray 2 are separated and taken...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com