Full-automatic horizontal rubbing swing washer and washing mode

A fully automatic, washing machine technology, applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problem of high cost of use, and achieve the effects of safe and convenient use, saving detergent, and large changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

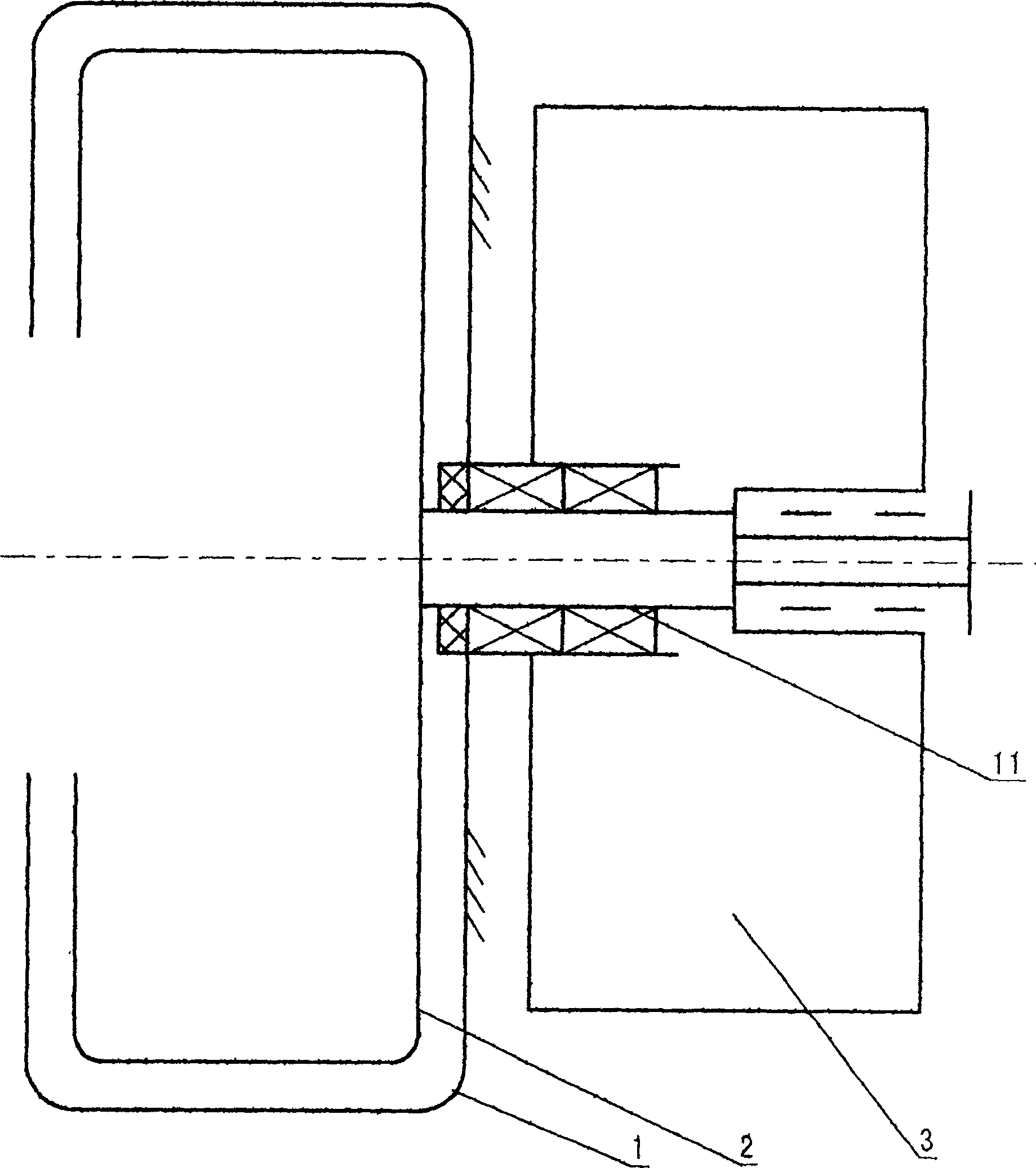

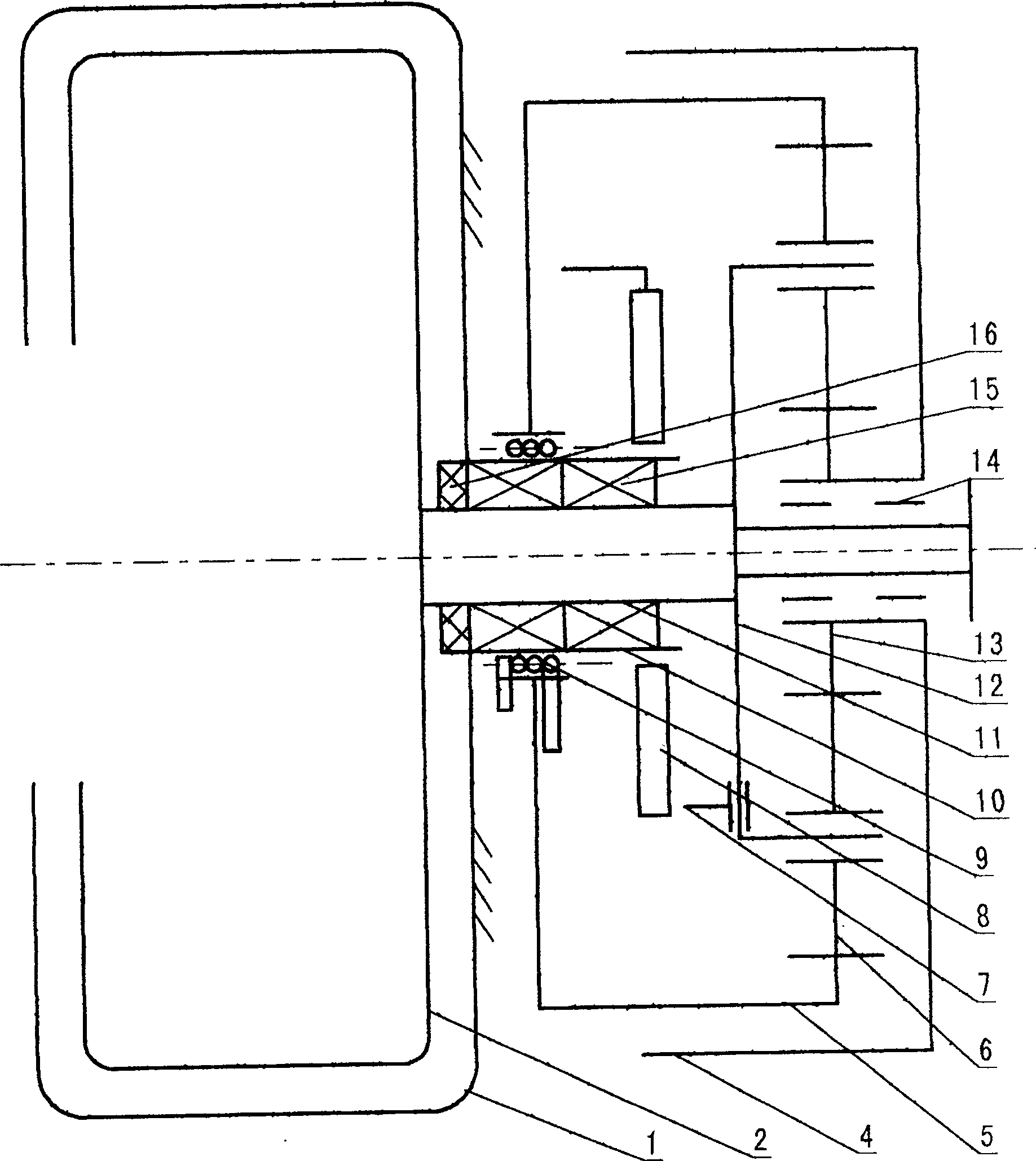

[0021] to combine figure 1 , figure 2 , a fully automatic horizontal scrubbing washing machine, its outer cylinder bearing seat 10 is located in the center of the outer cylinder 1, fixed, and the inner cylinder shaft 11 is fixed in the center of the inner cylinder 2, passing through the large water seal 16 and the rolling bearing 15, The inner cylinder 2 rotates in the outer cylinder 1, and the inner cylinder 2 is connected with the horizontal automatic deceleration clutch 3 through the inner cylinder shaft 11. The horizontal fully automatic deceleration clutch 3 is mainly composed of an internal gear 5, a planetary gear 6, an input shaft gear 13, a planet carrier 12, a pulley 4 and an inner cylinder shaft 11, the input shaft gear 13 is fixedly connected with the pulley 4, and a sliding bearing 14 is installed in it. , sleeved on the inner cylinder shaft 11, the planetary gear 6 meshes with the input shaft gear 13 and the inner gear 5, and the planet carrier 12 is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com