Dismountable composition type piezolighter in high stability

A high-stability, combined technology, used in high-stability piezoelectric igniters, combined, and disassembled fields, can solve the problems of cracking, improving, and increasing the possibility of internal discharge, etc., to avoid cracking and ensure Effect of release efficiency and energy loss avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

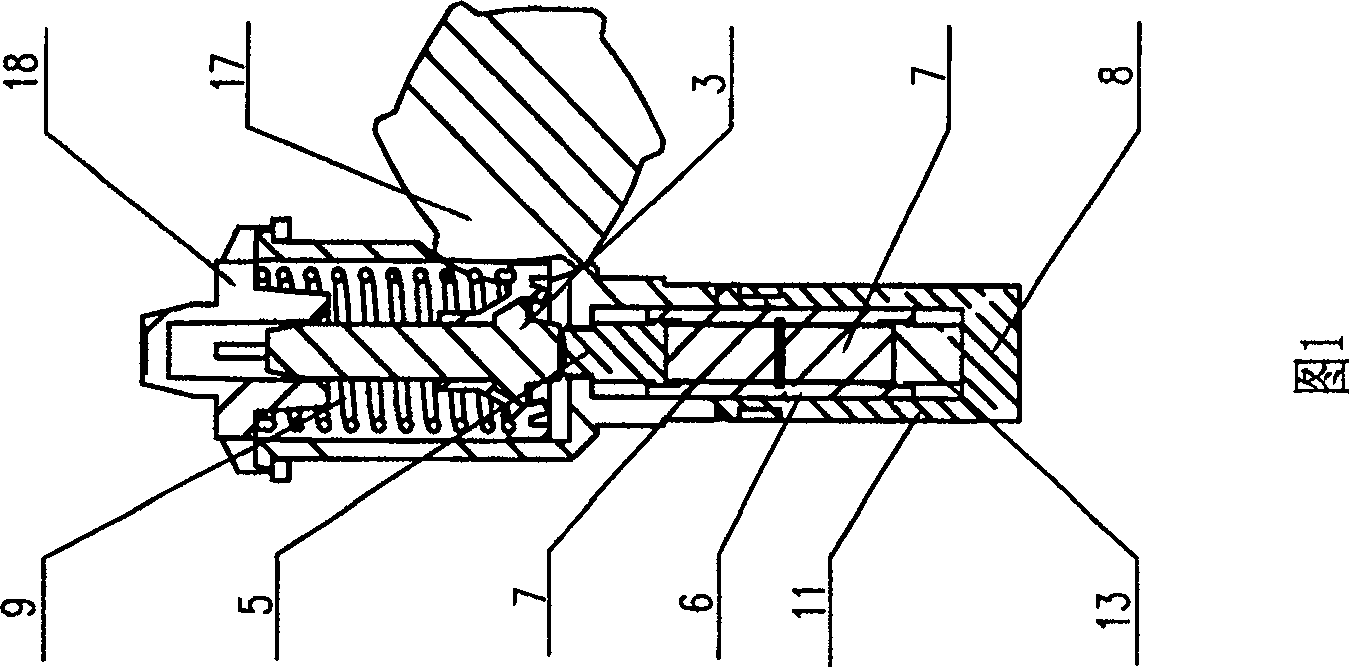

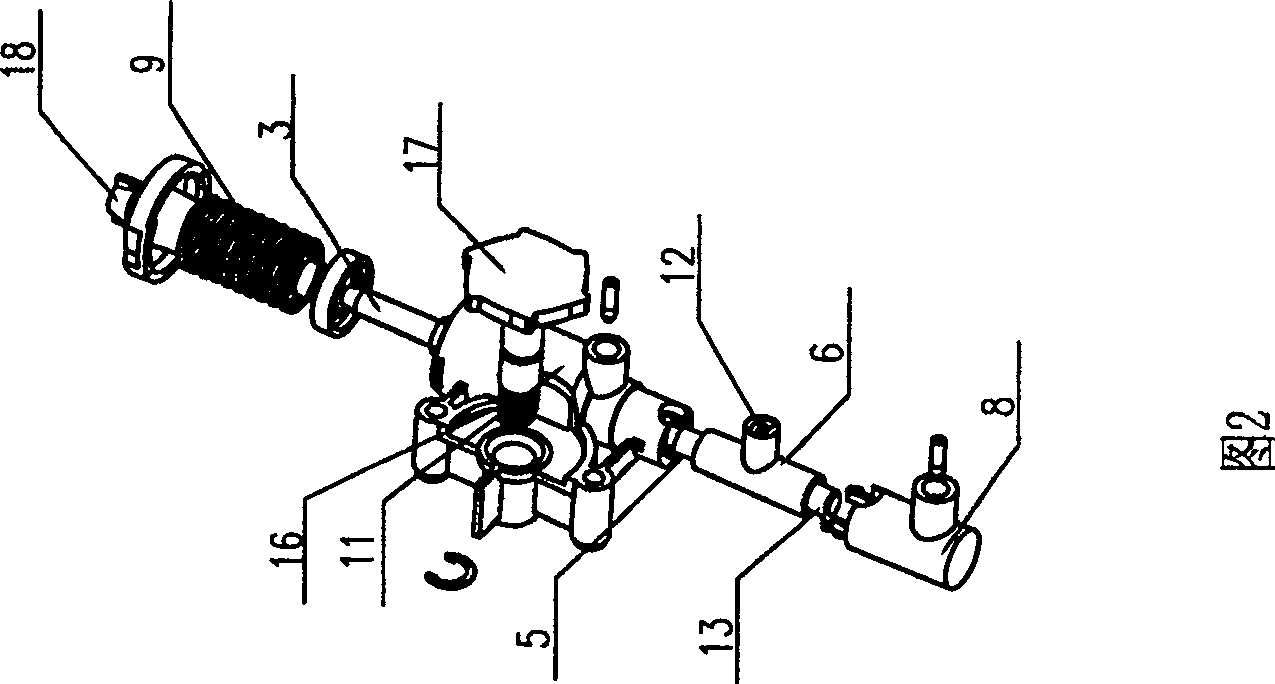

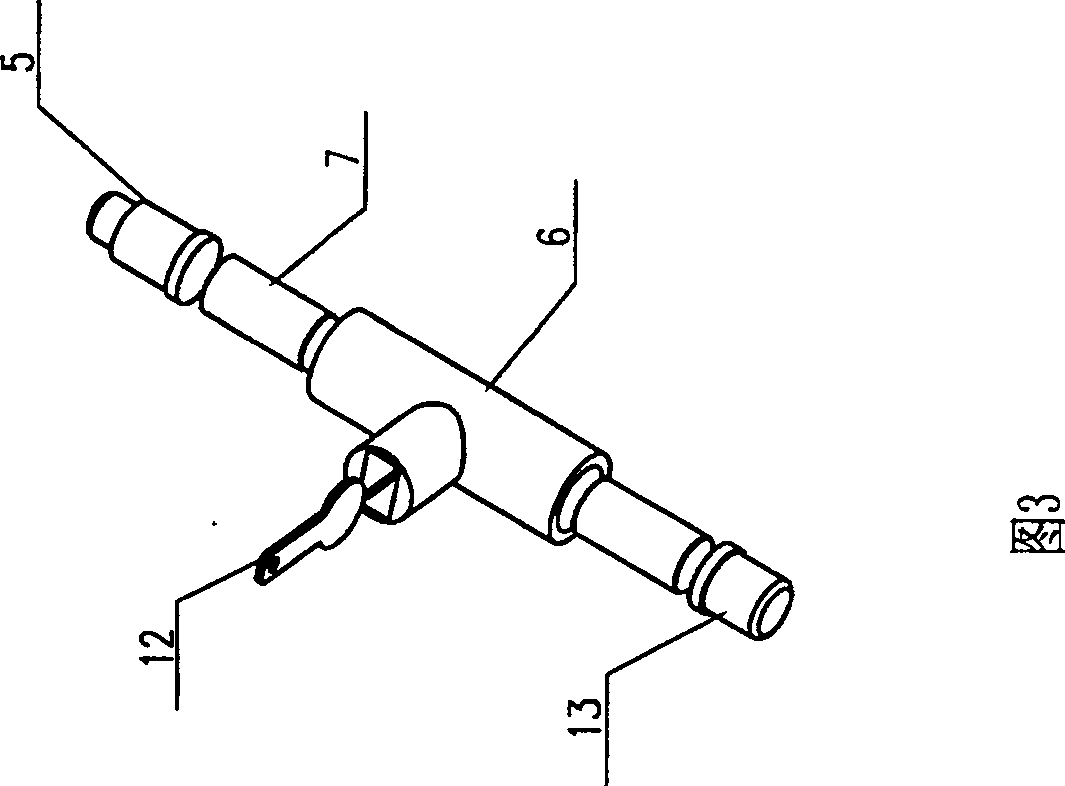

[0032] As shown in Figure 1, Figure 2 and Figure 3, the detachable combined high-stability piezoelectric igniter of the present invention includes a firing device, a housing 11, a base 8 and a piezoelectric anvil 5, a piezoelectric seat 13, a piezoelectric A piezoelectric ceramic assembly composed of electric ceramics 7, electrode sheets 12, and three-way body 6. The firing device is composed of a firing spring 9, a hammer 3 and a knob 16. A ratchet 17 is arranged at the bottom end of the knob 16 on the firing device. The ratchet 17 is clamped with the hammer 3, and the hammer 3 and the firing spring 9 on the firing device are packaged in the housing 11 through the end cover 18. The piezoelectric ceramic assembly is composed of a piezoelectric ceramic 7 and a piezoelectric anvil 5. And piezoelectric seat 13 is combined in three-way body 6, and this three-way body 6 is arranged as the transparent plastic part that has three passage outlets, and is filled with Liquid insulating ...

Embodiment 2

[0035] In another embodiment shown in Fig. 3, Fig. 4 and Fig. 5, different from the above-mentioned embodiment 1, the firing device is composed of a firing spring 9, a return spring 10, a hammer 3, a cross bar 2 and a button 1, and the firing The hammer 3 and firing spring 9 on the device are combined in the button housing, and the base 8 is provided with a ground rod 14 extending into the bottom of the housing 11 to contact the return spring 10 on the firing device.

[0036] During the installation process, drop liquid insulating glue into the inner cavity of the tee, fill the piezoelectric ceramic anode towards the electrode piece, respectively fill the two inner cavities and press them tightly, and then install the piezoelectric anvil and piezoelectric seat to press them tightly, and then use The press-sealing machine hot-presses and solidifies the plastic on the peripheral end faces of the three-way body, the piezoelectric anvil, and the piezoelectric seat, thus completing ...

Embodiment 3

[0038] As shown in Fig. 3, Fig. 5 and Fig. 6, different from the above two embodiments, the firing device is composed of a firing spring 9, a return spring 10, a hammer 3, and a button 1, and the firing device passes through a movable end cover 19 Encapsulated in the housing 11, a hole is provided in the middle of the movable end cover 19, and the button 1 passes through the hole and movably connects with the housing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com