Impact tool

A technology of impact tools and tools, which is applied in the field of impact tools, can solve problems such as loud noise, and achieve the effect of reducing noise and preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

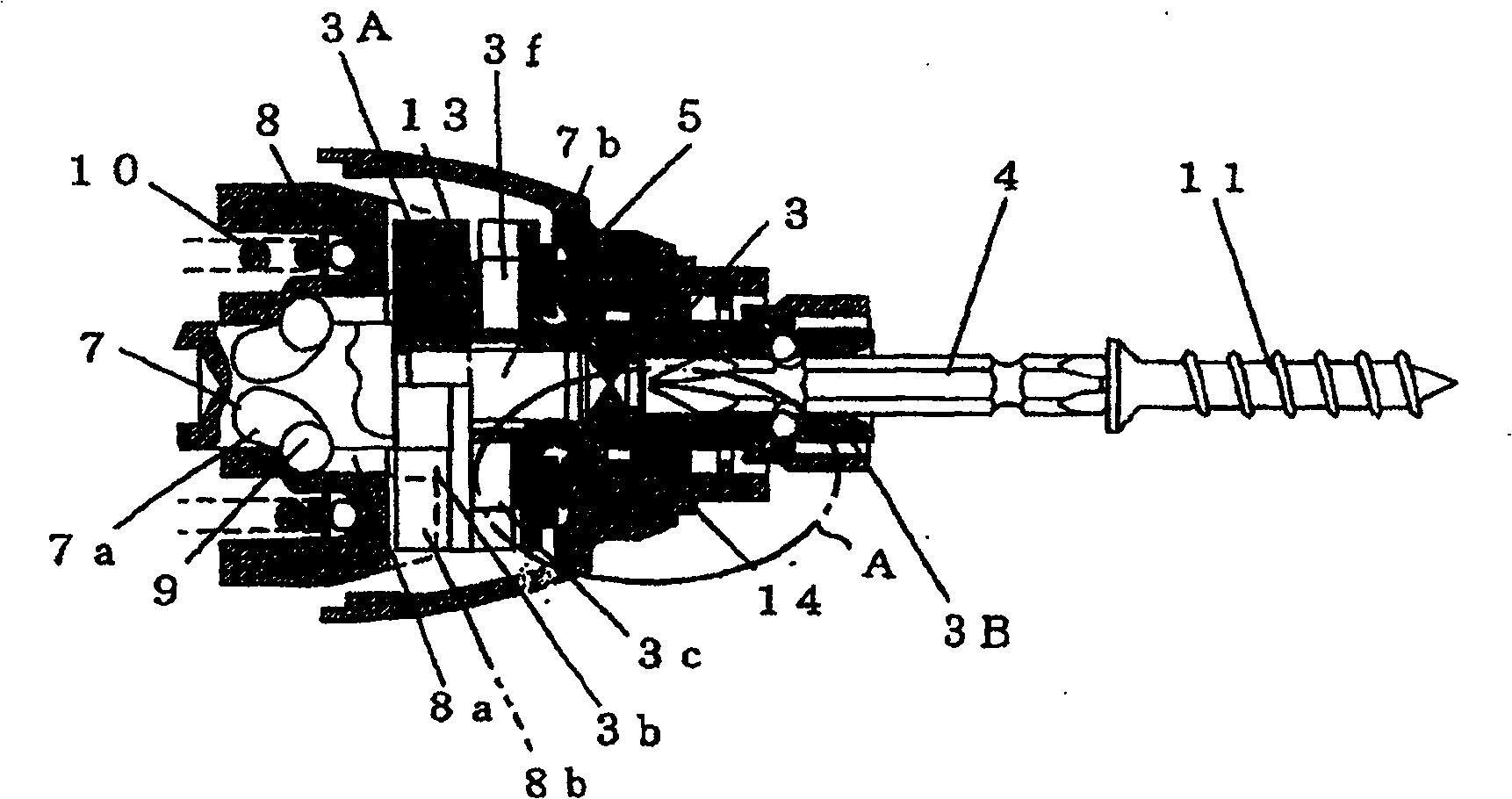

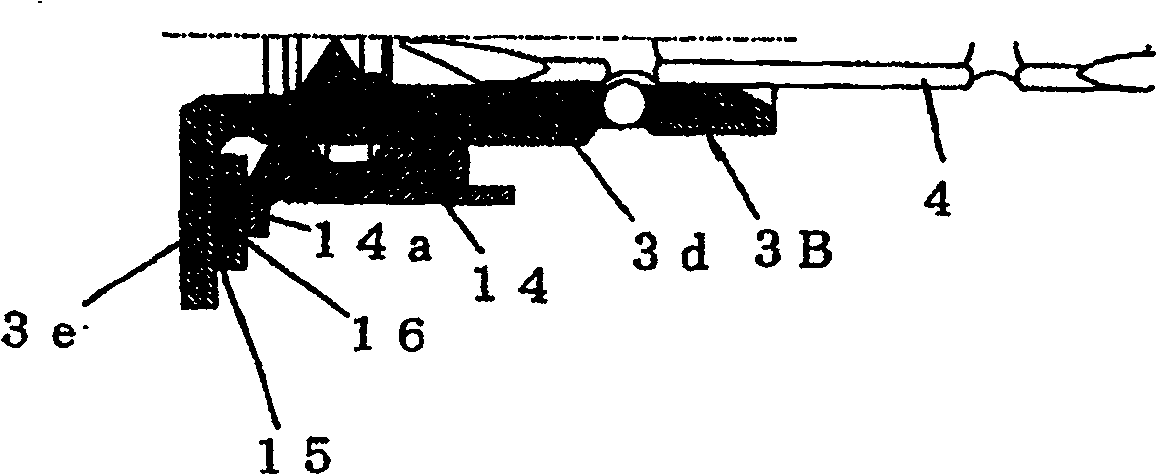

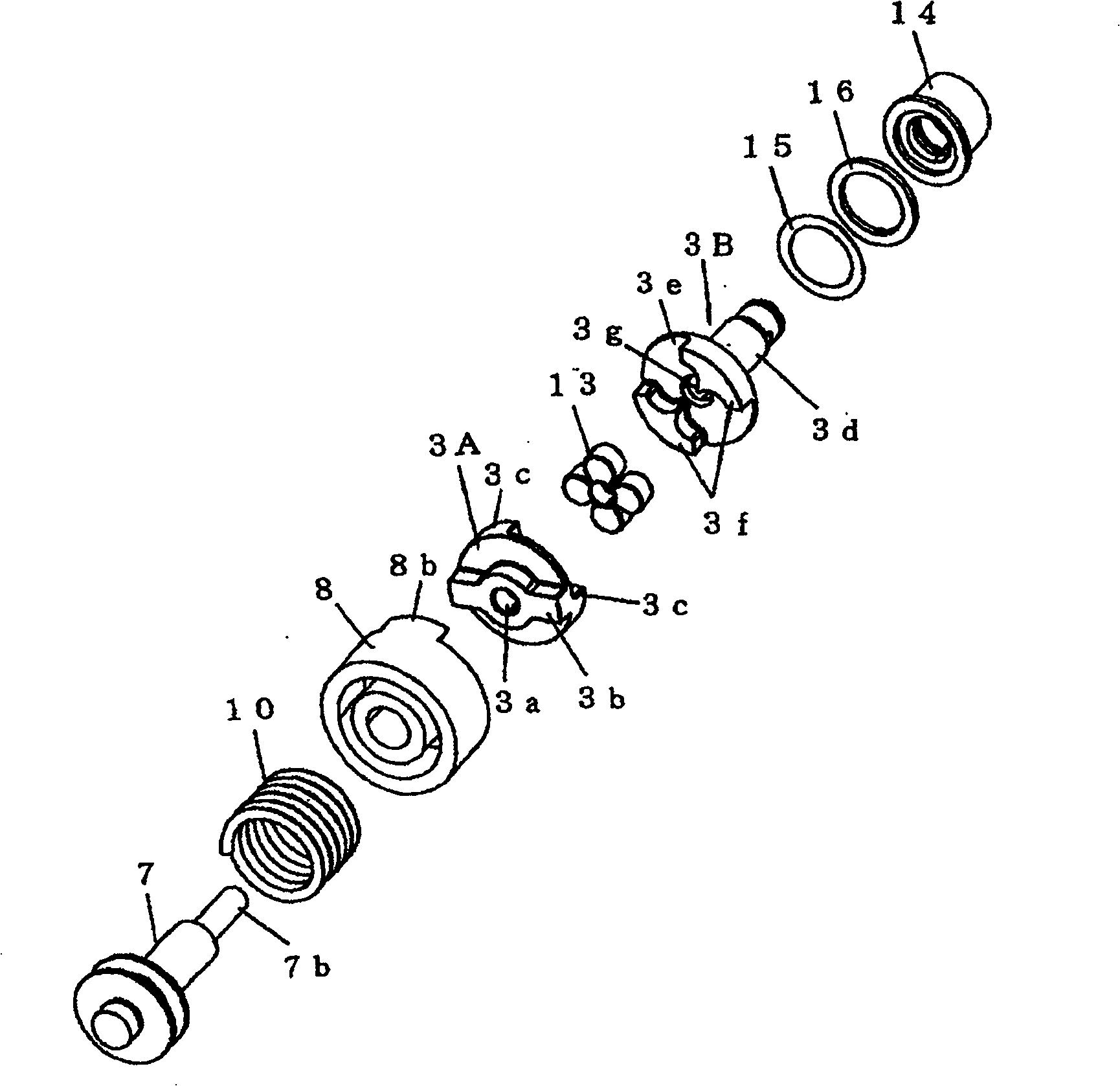

[0039] figure 1 To show a longitudinal sectional view of the rotary impact mechanism portion of the impact tool according to the present embodiment, figure 2 is a view showing details of part A on an enlarged scale, image 3 with 4 To show an exploded isometric view of the rotary impact mechanism portion of the impact tool, Figure 5 To show a side view of the anvil, and, Figure 6 along Figure 5 Sectional view taken along midline B-B.

[0040] The impact tool according to the present embodiment is a cordless, portable tool having a battery pack as a power source and a motor as a drive source, and its configuration is the same as that of the conventional impact tool shown in FIG. 12 except for a part thereof. Therefore, a repeated description of the same configuration as that shown in FIG. 12 is omitted, and only a description is given of a configuration unique to the present invention.

[0041] The impact tool according to the present embodiment is characterized in that...

Embodiment 2

[0066] Next, Embodiment 2 of the present invention will be described with reference to FIGS. 10 and 11 . In addition, FIG. 10 is a longitudinal sectional view showing the rotary impact mechanism portion of the impact tool according to the present embodiment, and FIG. 11 is an enlarged sectional view taken along line C-C in FIG. figure 1 with 2 Components that are the same as those in are denoted by the same reference numerals as the latter.

[0067] The impact tool according to the present embodiment has a feature that the buffer mechanism is provided on the tip tool 4 . Here, the buffering mechanism realizes the buffering function in the direction of rotation and in the axial direction, and directly transmits the set value or greater torque in the same manner as in Embodiment 1. The buffering mechanism specifically includes: split parts 4A, 4B, by The tip tool 4 is provided split in half in the axial direction; and a rubber damper 17 is interposed between the two split piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com