Method and apparatus for the conveyance of fine-grained solids

A fine-grained, solid-state technology used in chemical instruments and methods, lighting and heating equipment, direct-contact heat exchangers, etc., to solve problems such as corrosion, particle disintegration, and blockage of gas supply pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

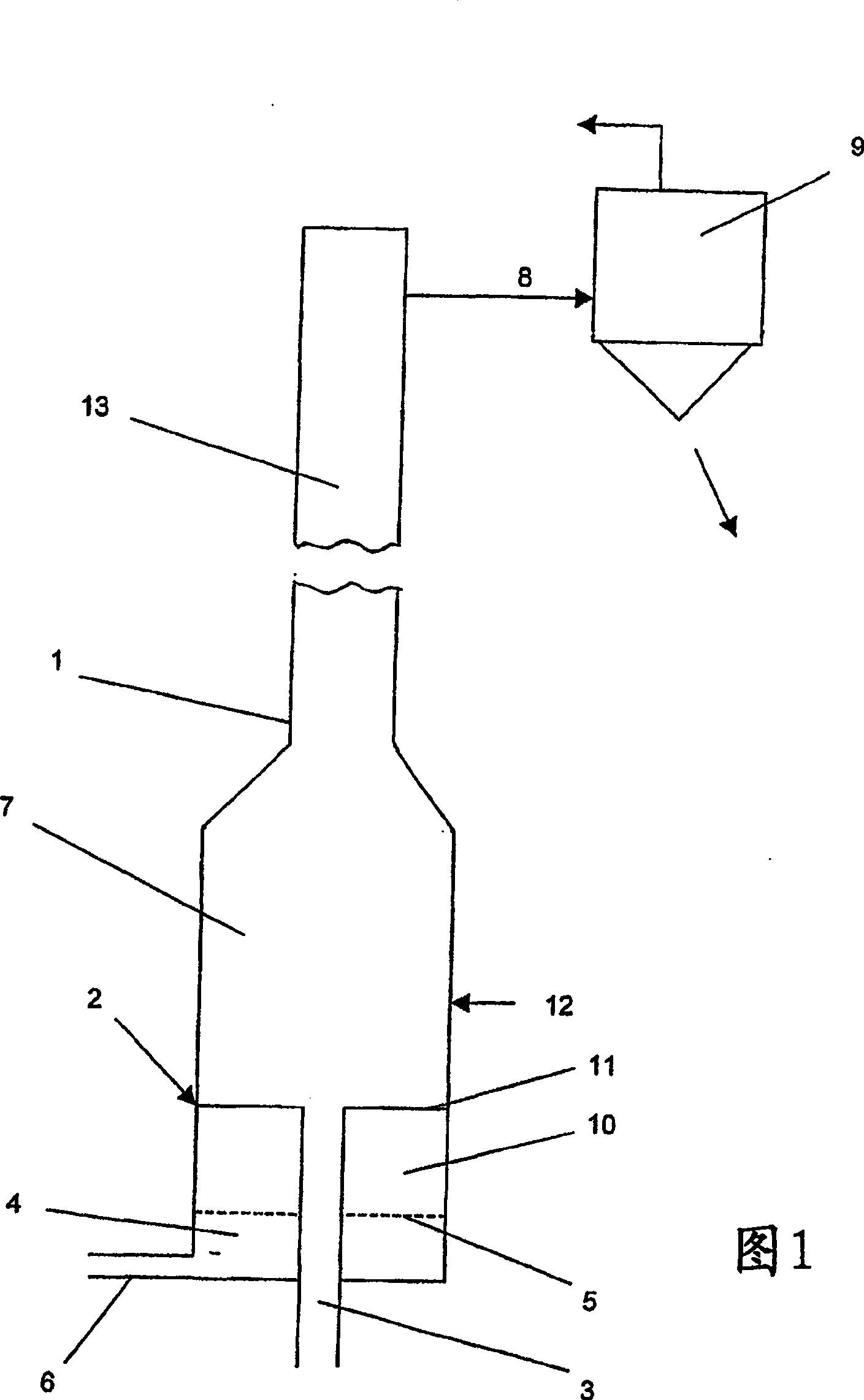

[0048] Example 1 (Heat transfer and transportation of Fe under oxidizing conditions 2 O 3 Or titanium-containing ore)

[0049] In the device corresponding to the figure, 65.7t / h Fe 2 O 3 The reactor supplied for transportation may also be dried in an oxidizing atmosphere. In addition, as a conveying medium, 1000Nm is supplied to the reactor 1 through the pipeline 6 3 / h of air, 12300Nm is supplied through the central pipe 3 3 / h of air with a temperature of 50°C. The latter is in the center tube 3 with 532Nm before entering the annular fluidized bed 10 3 / h Natural gas blend as fuel. Take out 65.7t / h Fe with a temperature of 1000℃ from the reactor through pipe 8. 2 O 3 .

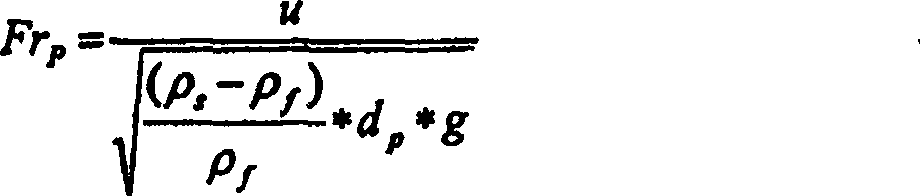

[0050] The fluidization condition with the Frud number of particles in the mixing chamber 7 is about 3, so that the natural gas is combusted internally without a temperature peak. With this method, the temperature loss in the reactor 1 caused by the radiation of the reactor wall and the mixing of solids and cold...

Embodiment 2

[0054] Example 2 (conveying and heating sponge iron)

[0055] In the device corresponding to the figure, fine-grained sponge iron of 68 t / h with a temperature of about 650° C. is fed into the reactor 1 through the supply pipe 2.

[0056] Set the temperature to 40000Nm at 900℃ 3 / h of hydrogen is supplied to the reactor 1 from the upstream reduction section for iron ore through the central pipe 3, and the temperature is 750Nm of ambient temperature 3 / h of hydrogen is supplied to the reactor 1 through the gas distributor chamber 4. In this case, the gas velocity is selected so that the Frude number of the particles in the annular fluidized bed 10 is about 0.15, the Frude number of the particles in the mixing chamber 7 is about 1.8, and the Frude number of the particles in the central pipe 3 is about 1.8. The number is about 8.

[0057] In this way, the fine-grained sponge iron can be transported in the reactor 1 to a height of about 50 m, and at the same time it is heated to the te...

Embodiment 3

[0057] In this way, the fine-grained sponge iron can be transported in the reactor 1 to a height of about 50 m, and at the same time it is heated to the temperature required by the downstream briquetting process, so that the sponge iron agglomerates can be formed. Example 3 (transporting and cooling cement)

[0058] In the device corresponding to the figure, 68 t / h of fine-grained cement with a temperature of about 600° C. is fed into the reactor 1 through the supply pipe 2.

[0059] Set the temperature to 6250Nm at 50℃ 3 / h of air is supplied to the reactor 1 through the central pipe 3 as the conveying medium, and then 750Nm with a temperature of 50℃ 3 / h of air is supplied to the reactor 1 through the gas distributor chamber 4 as fluidizing gas. In this case, the gas velocity is selected so that the Frude number of the particles in the annular fluidized bed 10 is about 0.15, the Frude number of the particles in the mixing chamber 7 is about 1.8, and the Frude number of the parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com