Crankcase of opposited engine with double cylinders

A technology of engine and crankcase, which is applied in the field of crankcase, can solve the problems of high production cost, inconvenient maintenance, high scrap rate, etc., and achieve the effects of reducing production cost, facilitating maintenance and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

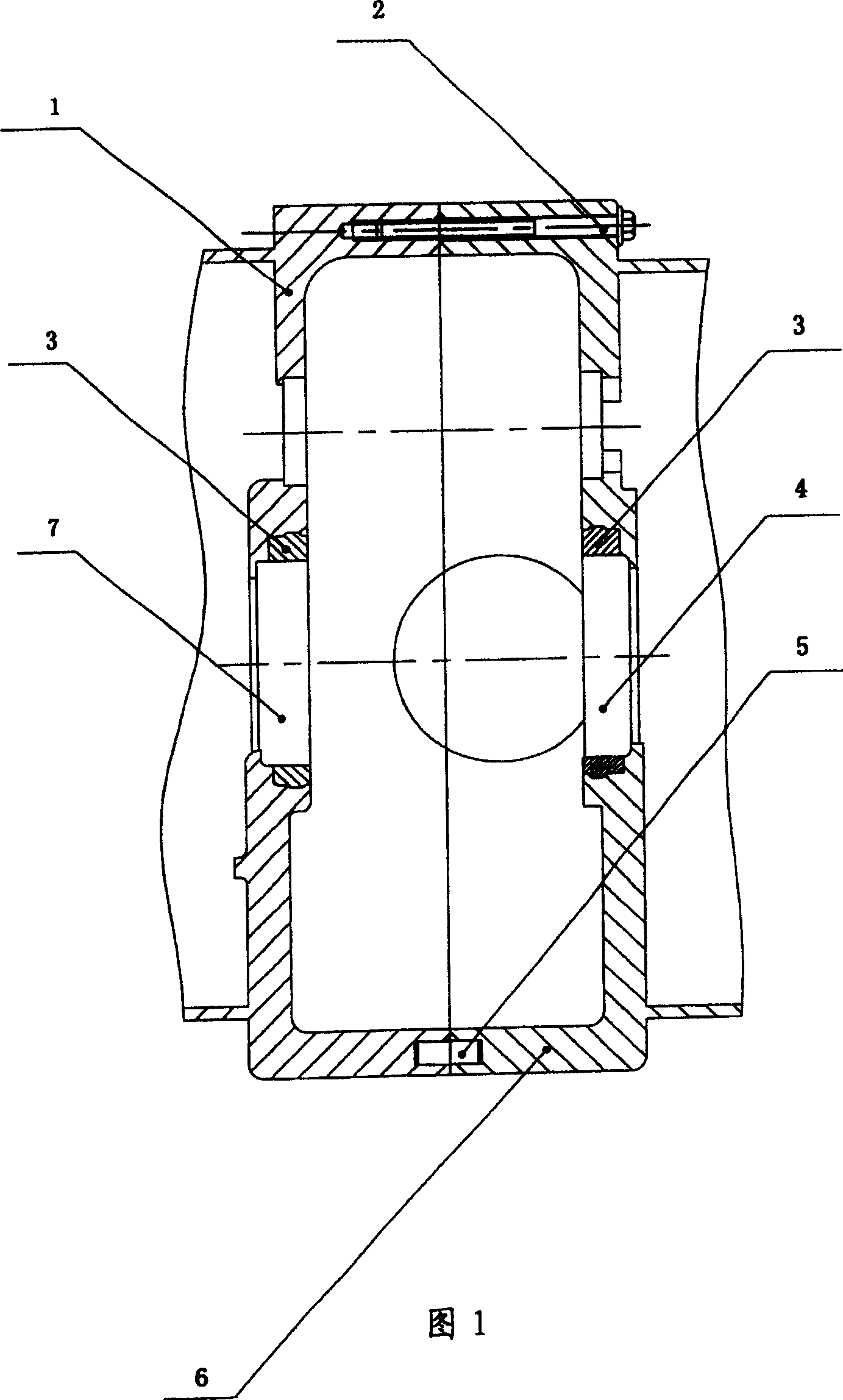

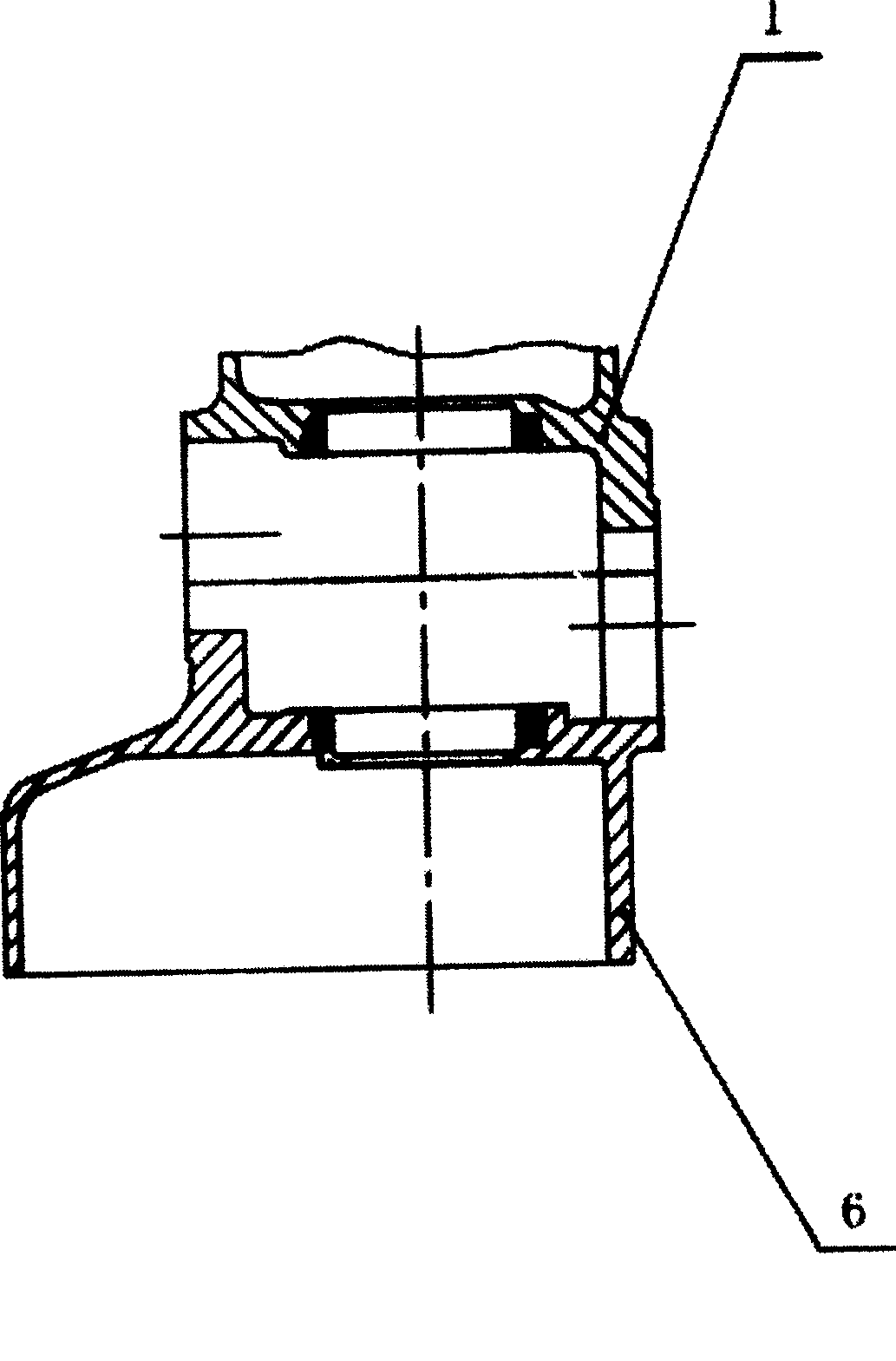

[0018] Below in conjunction with the accompanying drawings and preferred embodiments, the structure, features and effects of the crankcase of the opposed twin-cylinder engine proposed according to the present invention are described as follows.

[0019] Fig. 1 shows an embodiment of the lateral split structure of the opposed twin-cylinder engine crankcase of the present invention, wherein, the engine crankcase body is divided into front casing 1 and rear casing according to the transverse direction perpendicular to the axis of the crankshaft 6. The front box body 1 and the rear box body 6 are combined and connected by using two positioning pins 5 and several bolts 2 to form a complete box body. The crank bearing hole 7 of the front casing 1 and the crank bearing hole 4 of the rear casing 6 are integral structures, and in order to further improve the strength of the crankcase, an inlay 3 is added to the crank bearing hole, and the inlay 3 adopts such as Made of metal material. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com