Rack redundant electromagnetic driver of oil pump for diesel engine

An electromagnetic drive, diesel engine technology, applied in the direction of machines/engines, mechanical equipment, fuel injection pumps, etc., can solve the problems of uncontrollable, poor linearity and low reliability of the rotation angle sensor, to eliminate the rotation of the connecting platen and improve the acquisition accuracy , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

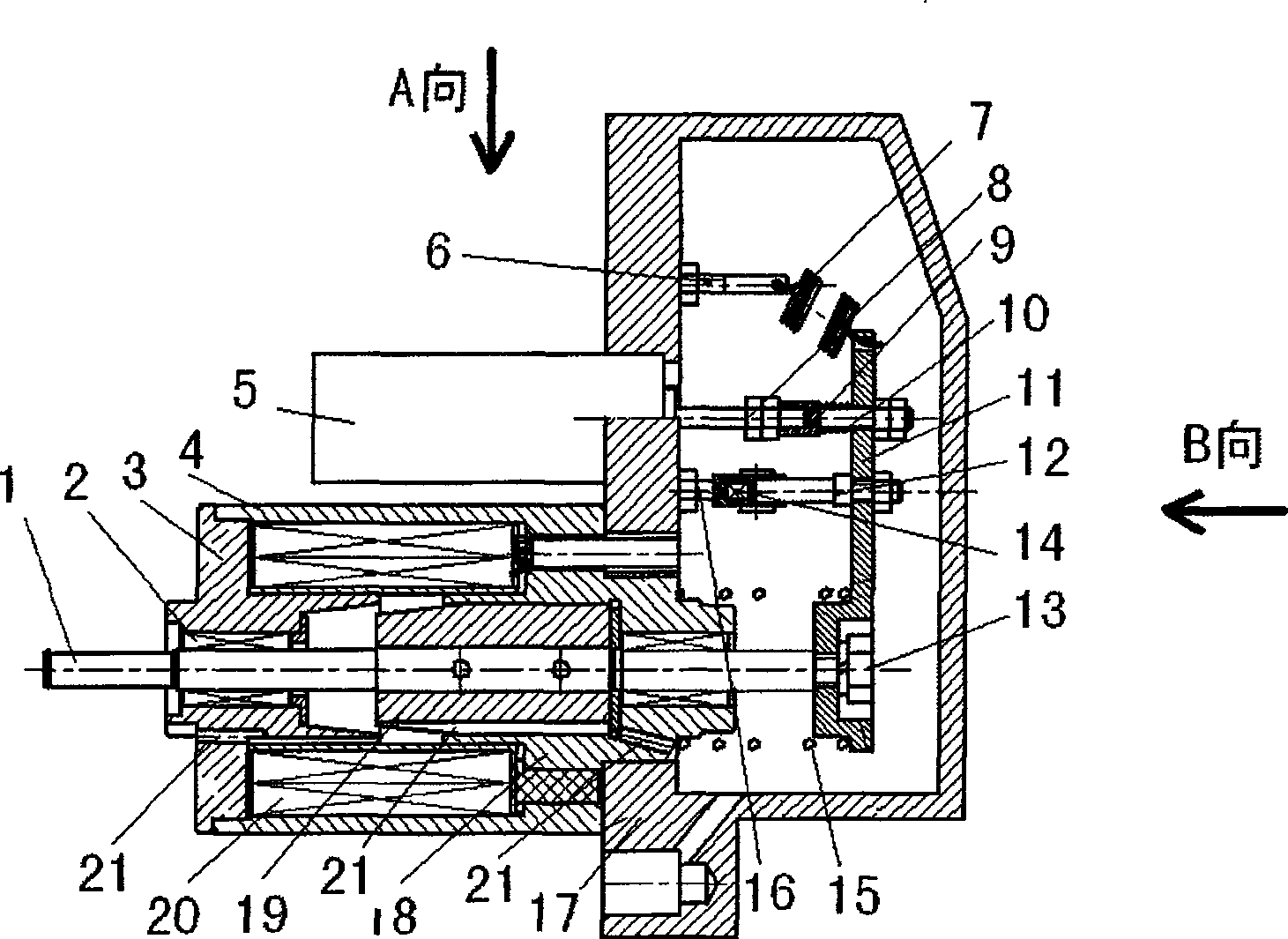

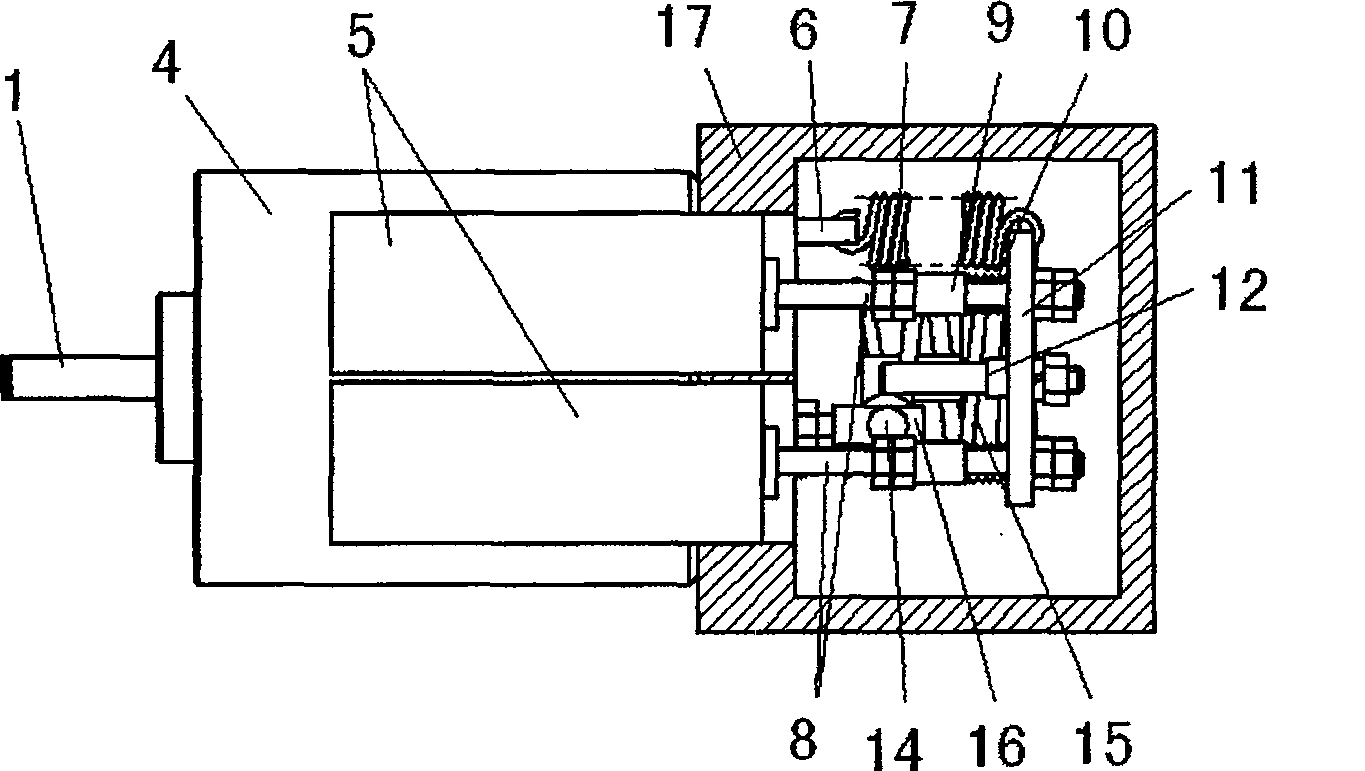

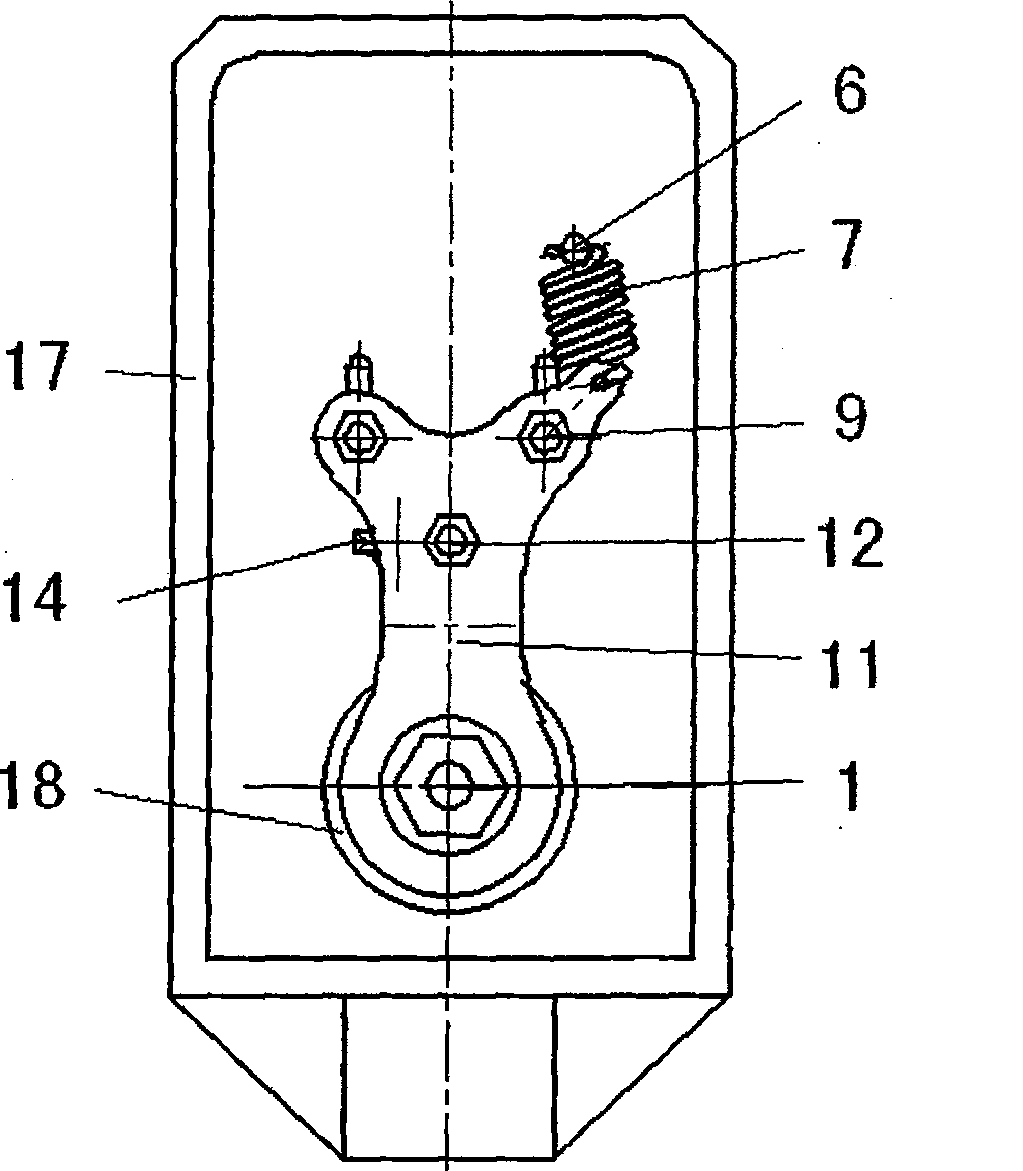

[0023] The preferred embodiments of the present invention are given below and described in conjunction with the accompanying drawings.

[0024] combine figure 1 , this embodiment includes a central shaft 1, a front end cover 3, a linear motion bearing 2, an outer shell 4, an armature 19, a rear end cover 18, a return spring 15, a double-winding coil 20, a rear housing 17, and two linear displacement sensors 5 , sensor sensing rod 8, positioning spring 7, positioning spring connecting rod 6, connecting pressure plate 11, guiding rod 12, guiding bearing 14, guiding bearing rod 16, sensor connecting rod 9, sensor fixing spring 10, fixing nut 13 and oil return passage twenty one. Among them, the front end cover 3, the outer shell 4, the rear end cover 18, and the armature 19 are made of pure electric iron DT4; the front end cover 3, the cylindrical outer shell 4 and the rear end cover 18 are coaxially inserted; the cylindrical double-winding coil 20 is embedded in the inner spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com