High-speed industrial door with a flexible curtain

A technology for flexible suspension and industrial doors, which is applied to doors, windows/doors, building components, etc. It can solve the problems of high sheet processing costs, material deformation restrictions, and increased costs, so as to avoid staining or oxidation, reliable and durable connections, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

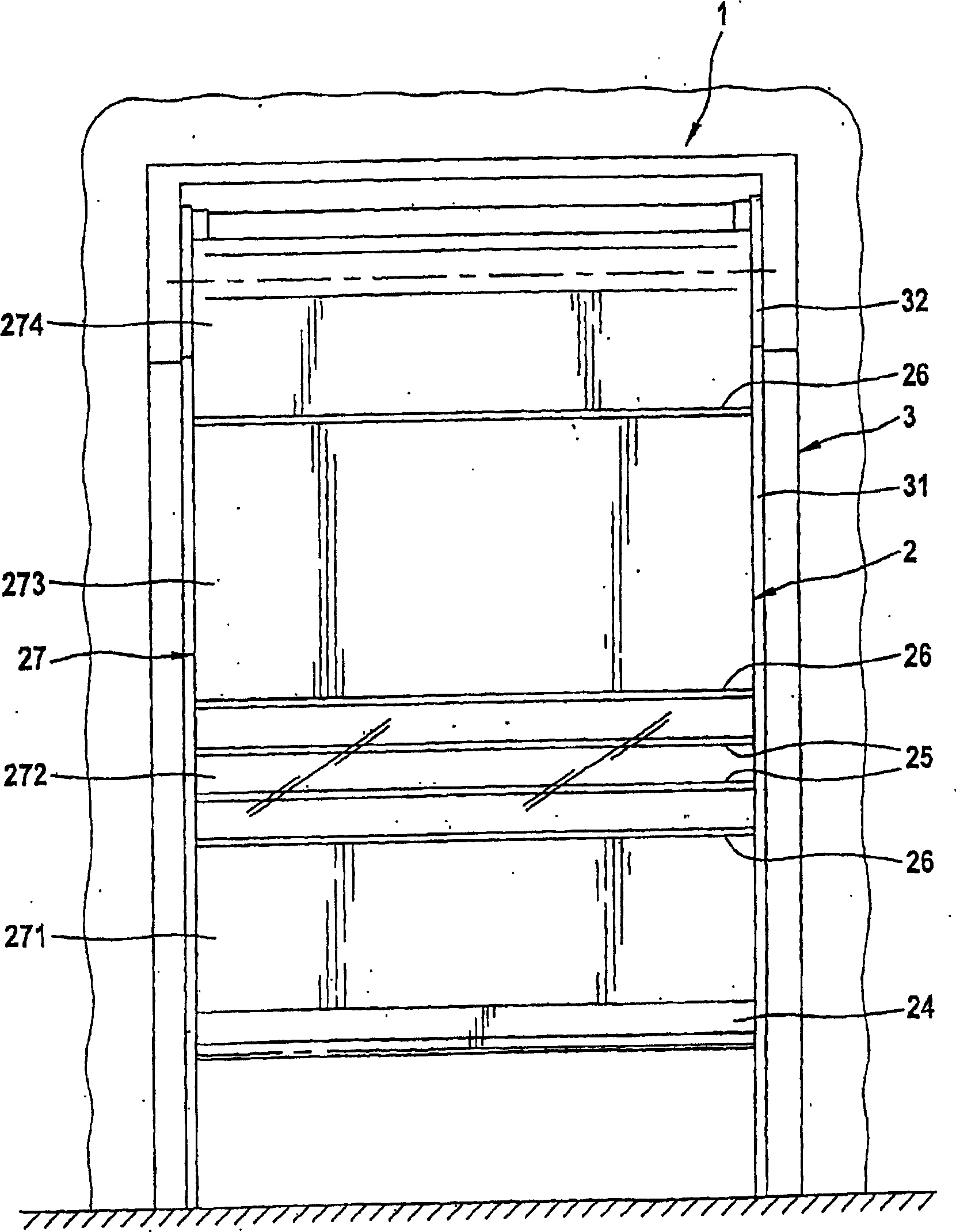

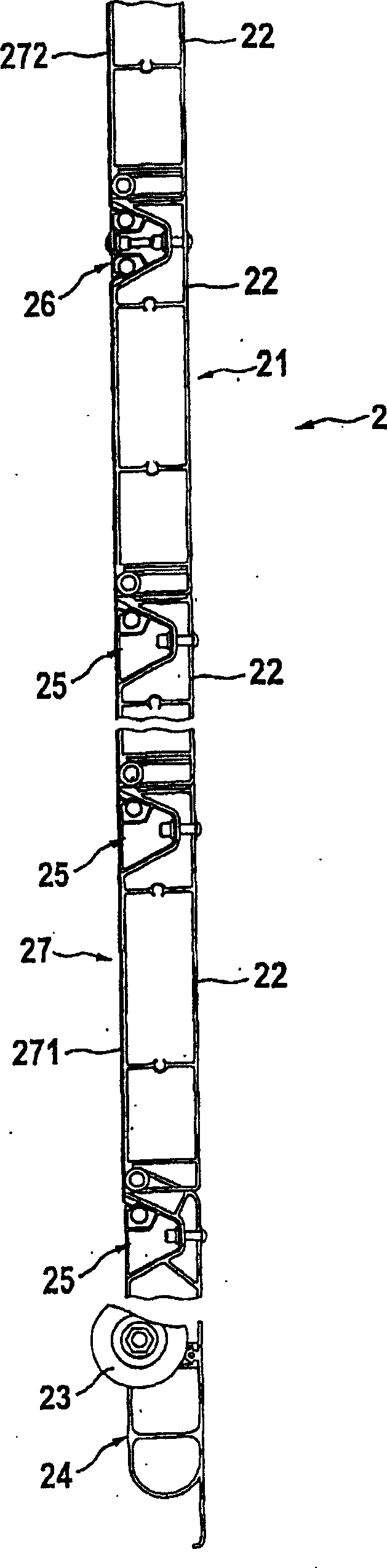

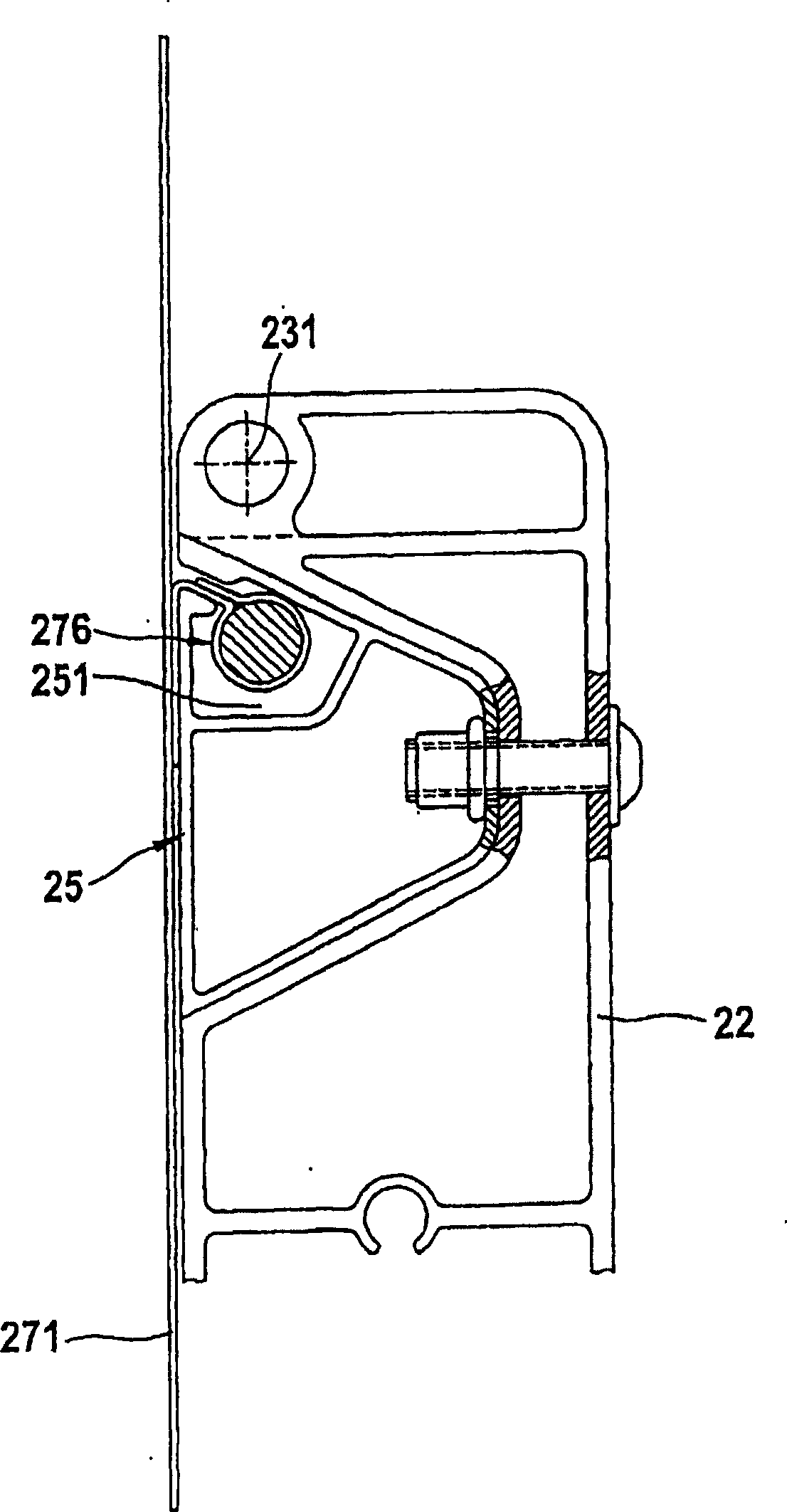

[0035] according to figure 1 The high-speed industrial door 1 shown has a door leaf part 2 which is accommodated in a door frame 3 and guided on both sides. The lateral guide in the door frame 3 has a vertical portion 31 in the area of the door opening and a spiral portion 32 in the area of the lintel of the door opening. Both sides of its door piece 2 have hinge band 21, and it is as figure 2 As shown, there are a plurality of flexible hinges 22 connected to each other on its side. They are guided in lateral guides by means of guide wheels 23, wherein for the sake of clarity in figure 2 Only one guide wheel is shown. The components guiding the door element 2 and the functions of these components are basically the same as those disclosed in DE 199 15 376 A1 and will not be described in detail here. Furthermore, its flap part 2 has a bottom-side end closure part 24 .

[0036] As shown in the figure, the door piece also includes two types of reinforcement structures, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com