Poly(vinyl chloride) fiber for artificial hair, method for producing the same

A polyvinyl chloride and artificial hair technology, applied in the direction of single-component halogenated hydrocarbon artificial filaments, applications, wigs, etc., can solve problems such as high melt viscosity, reduced fiber formability, broken filaments, etc., to achieve gloss suppression and maintenance Effects of fiber strength and fiber formability maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

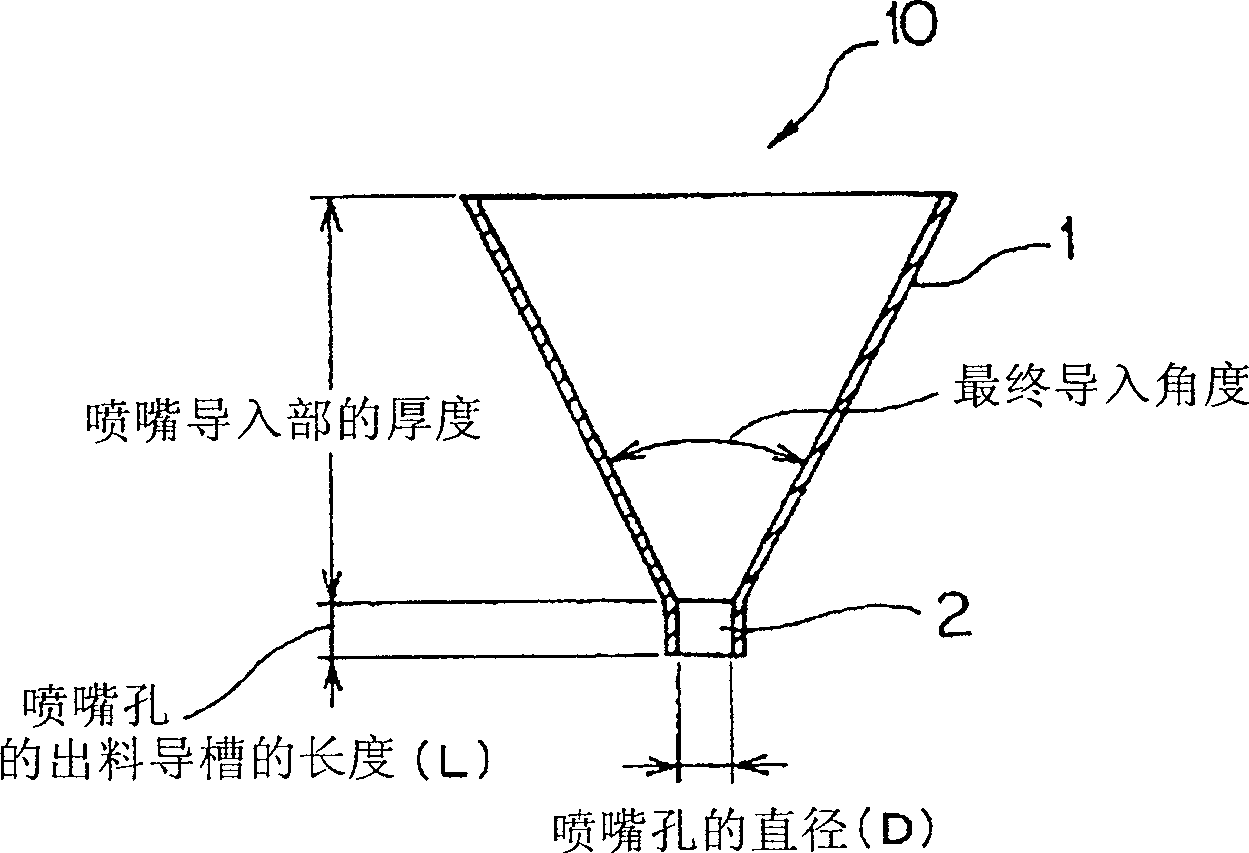

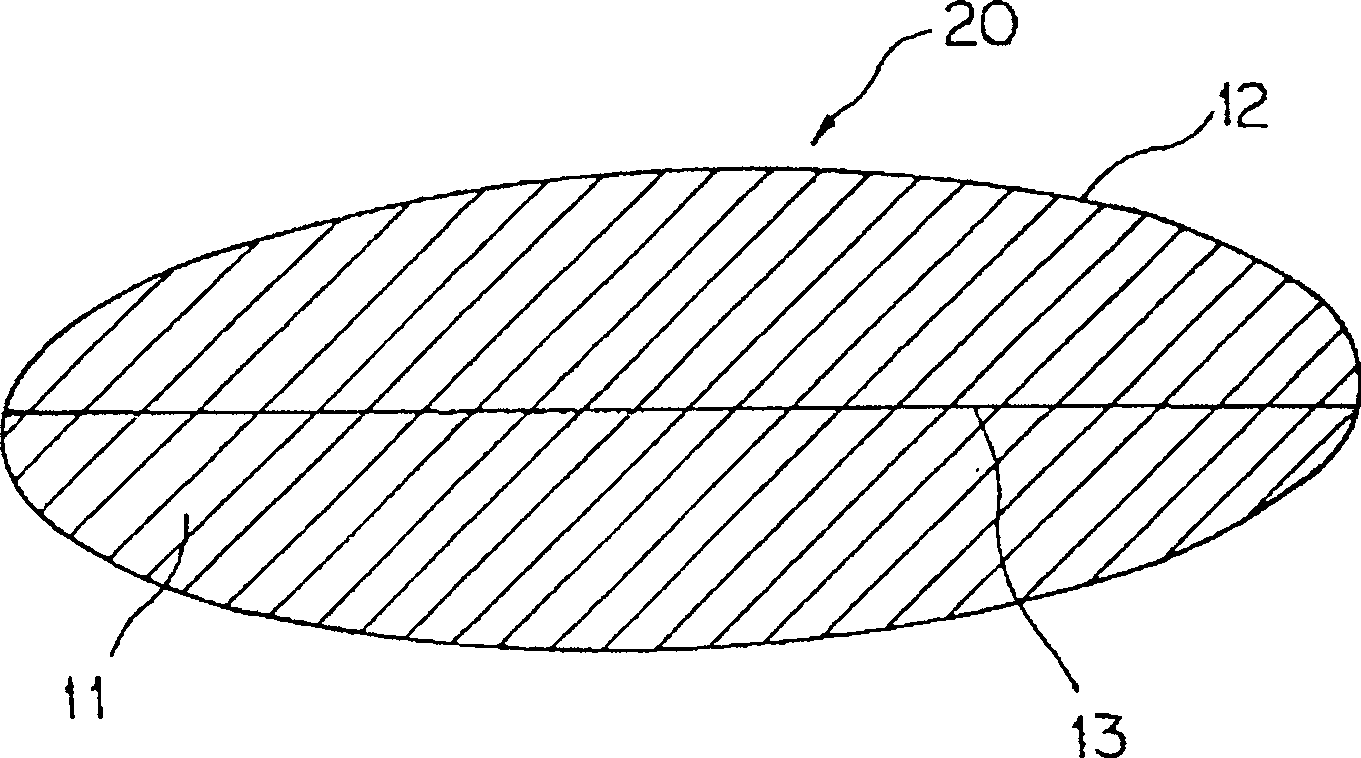

[0088] 100 parts by mass of polyvinyl chloride-based resin (manufactured by Taiyang Polyvinyl Chloride Co., Ltd., TH-1000), 3 parts by mass of hydrotalcite-based heat stabilizer (manufactured by Kyowa Chemical Co., Ltd., ALCAMIZER-1), 12 hydroxystearic acid 0.6 parts by mass of zinc (manufactured by Nissan Chemical Co., Ltd., NF-12Zn), 0.4 parts by mass of calcium 12-hydroxystearate (manufactured by Nissan Chemical Co., Ltd., NF-12Ca), and a high-grade fatty acid ester lubricant with a compounding ratio of 20 as a lubricant (Riken Vitamin Co., Ltd., EW-100) 4.0 parts by mass and polyethylene wax (Mitsui Chemicals, Inc., Hiwax400P) 0.2 parts by mass of polyvinyl chloride resin composition, from 120 nozzles with a cross-sectional area of 0.06mm 2 , the ratio of the diameter (D) of the nozzle hole and the length (L) of the discharge guide groove of the nozzle hole: L / D is 3, the thickness of the nozzle introduction part is 5mm, and the nozzle hole in the nozzle introduction part...

Embodiment 2

[0090] In addition to blending 1.0 parts by mass of a high-grade fatty acid ester lubricant (manufactured by RikenVitamin, EW-100) and 0.6 parts by mass of polyethylene wax (manufactured by Mitsui Chemicals, Ltd., Hiwax400P) at a compounding ratio of 1.7 as a lubricant, the above-mentioned implementation Example 1 Similarly, vinyl chloride-based fibers for artificial hair were obtained.

Embodiment 3

[0092] In addition to blending 0.2 parts by mass of a high-grade fatty acid ester lubricant (manufactured by RikenVitamin, EW-100) and 1.6 parts by mass of polyethylene wax (manufactured by Mitsui Chemicals, Ltd., Hiwax400P) with a compounding ratio of 0.1 as a lubricant, and using (L Mmax) / S=7.4 gear type mold carries out melt spinning, makes such as Figure 4 Vinyl chloride-based fibers for artificial hair were obtained in the same manner as in Example 1 above, except for polyvinyl chloride-based fibers having a gear-shaped cross-sectional shape and an average fineness of 180 denier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com