A device and a method for measuring torques of elevators

A technology of elevator braking and braking device, which is used in measuring devices, force/torque/work measuring instruments, transportation and packaging, etc., and can solve problems such as inability to obtain measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

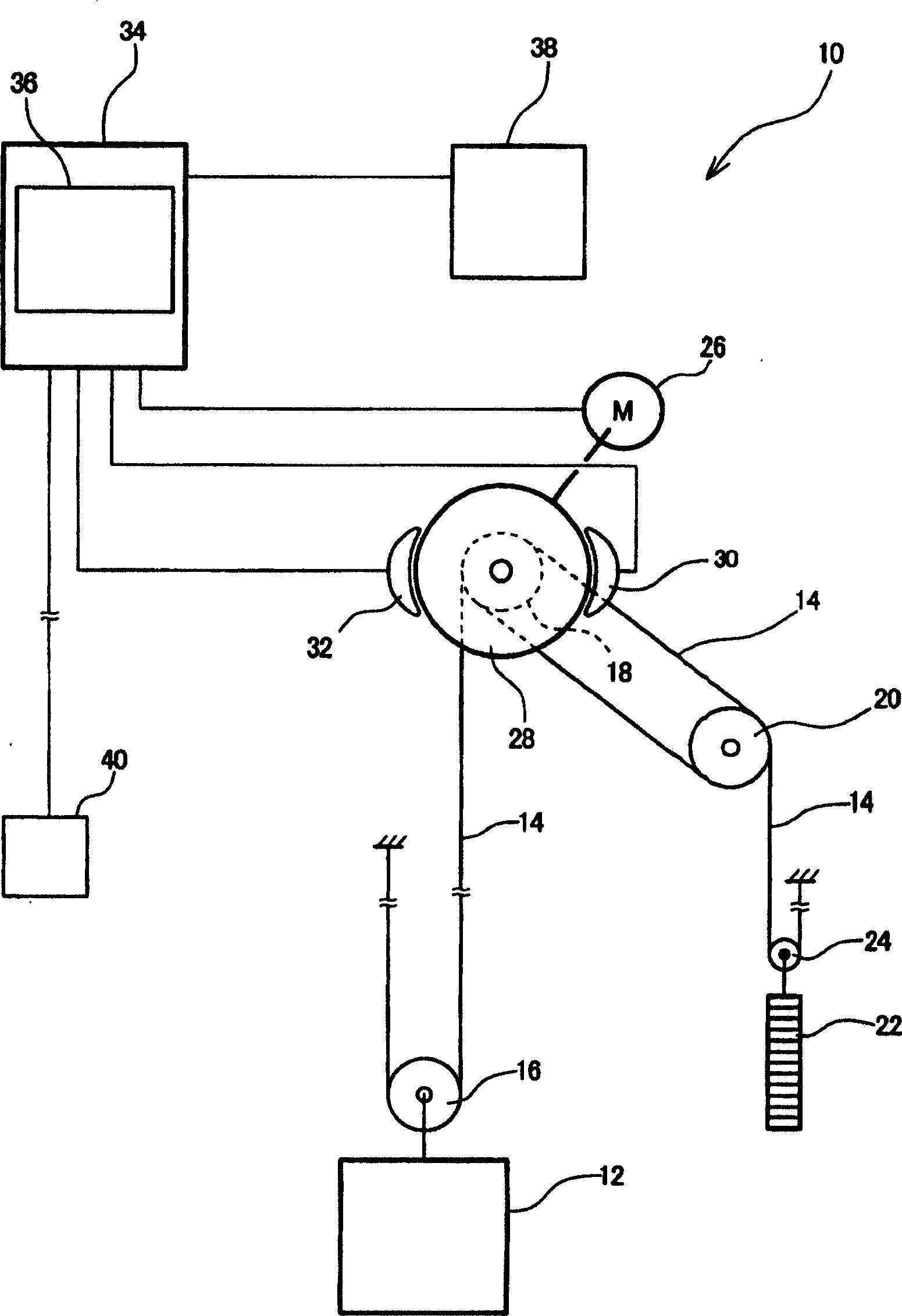

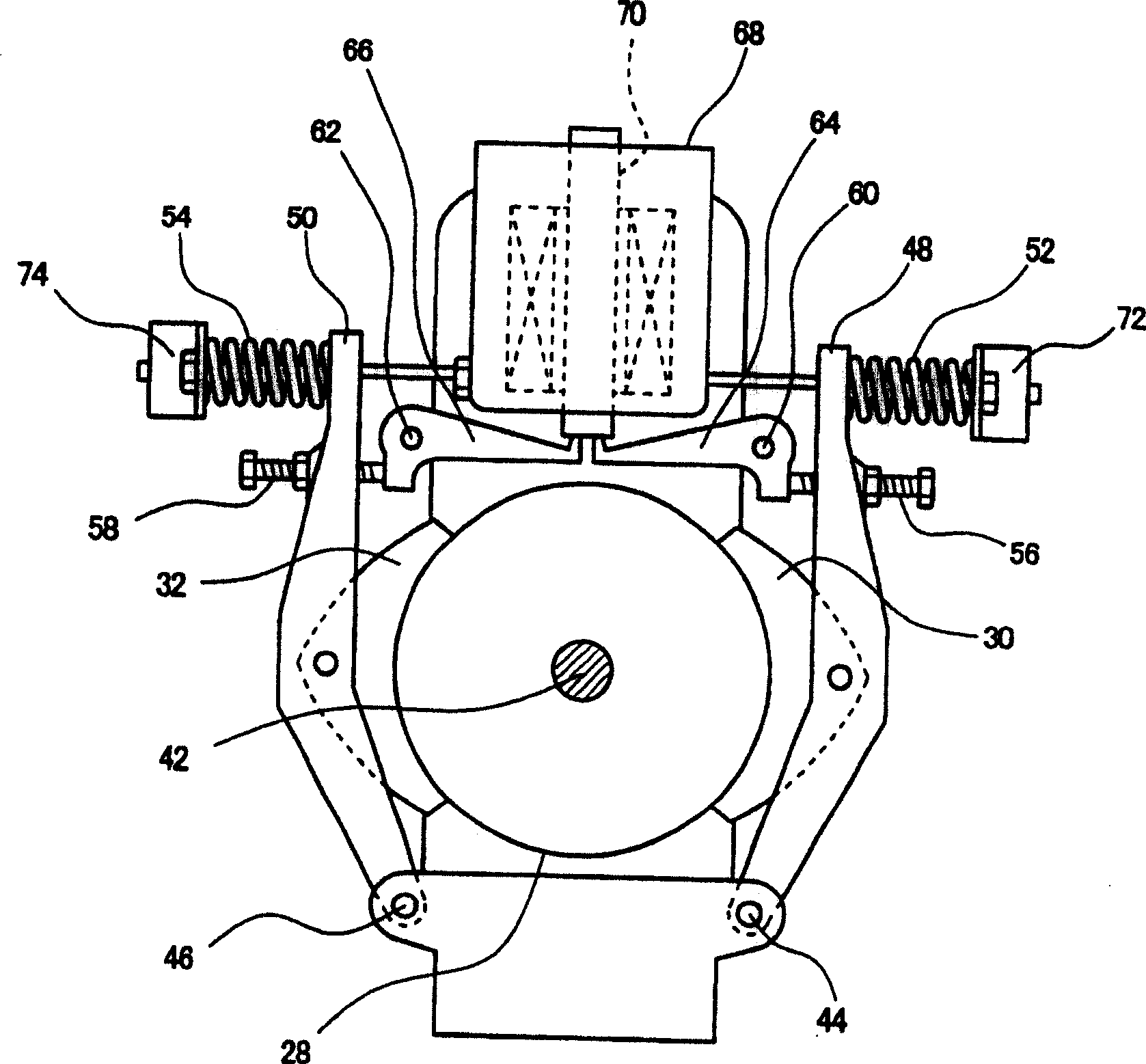

[0036] Embodiments of the present invention (hereinafter referred to as embodiments) will be described below with reference to the drawings. figure 1 It is a schematic configuration diagram showing the elevator 10 of the present embodiment. A box 12 carrying occupants or a load is suspended below hoist lines 14 . Lifting cable 14 stretches out from an end that is fixed on the building component above the casing, wraps around the suspension wheel 16 that is fixed on the casing 12, and then stretches to the drive pulley 18 that is arranged on the top of the hoistway. Go around on the drive pulley 18 and the deflector wheel 20 of the hoist and extend to the counterweight 22 again. On the pulley 24 fixed on the upper part of the balance weight 22, after the hoisting rope 14 is wound over the pulley 24, one end thereof is fixed on the building member. Like this, one end of hoisting rope is fixed on the member of building, also can adopt the suspension cable method other than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com