Tailoring method of aluminium cloth used for protecting refractory fiber modular structure furnace wall

A modular structure, refractory fiber technology, applied in lining repair and other directions, can solve the problems of easily deformed resistance belt, high construction strength, poor safety, etc., to eliminate potential safety hazards, reduce work intensity and construction cost, and solve the effect of production stoppage across the line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

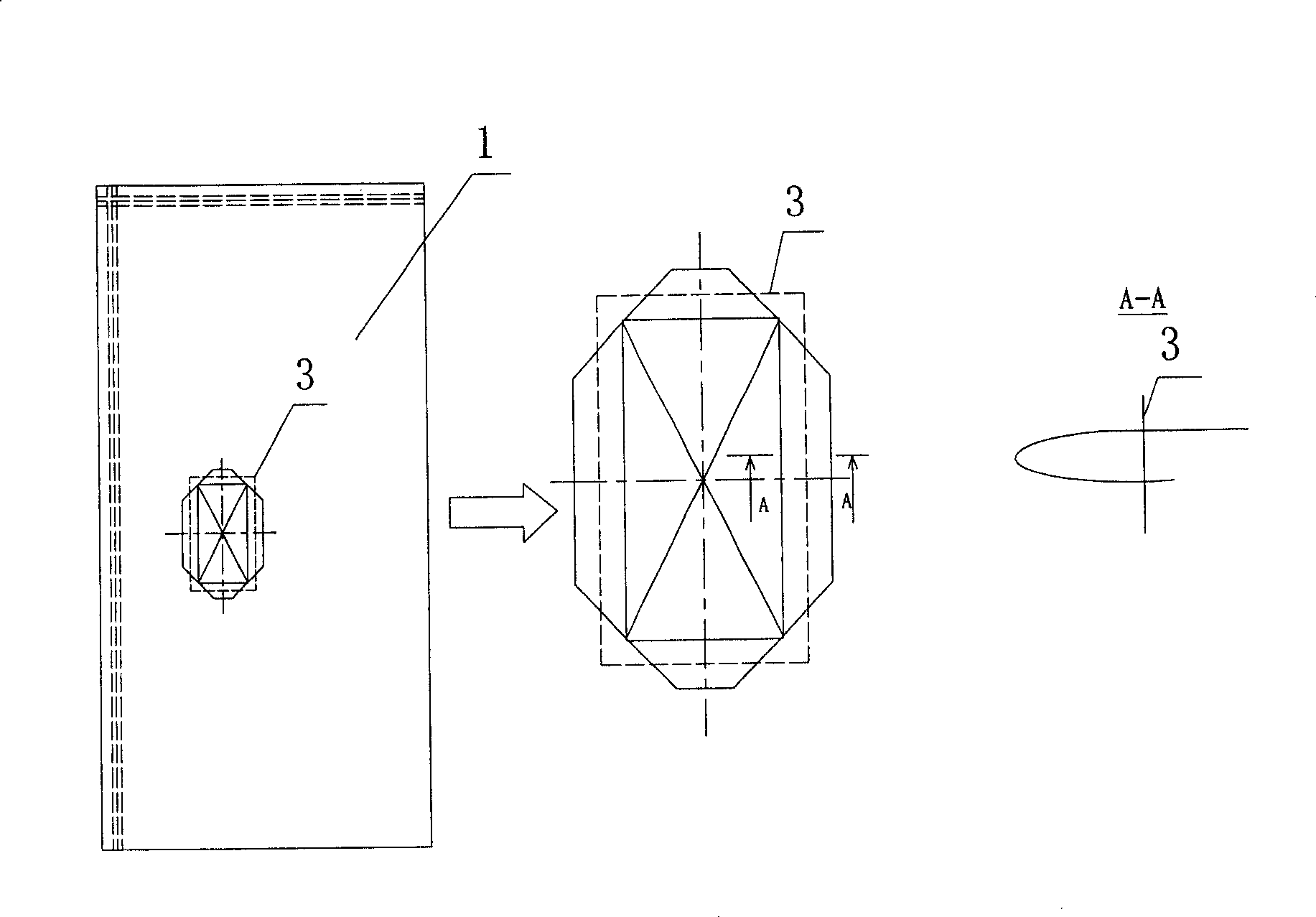

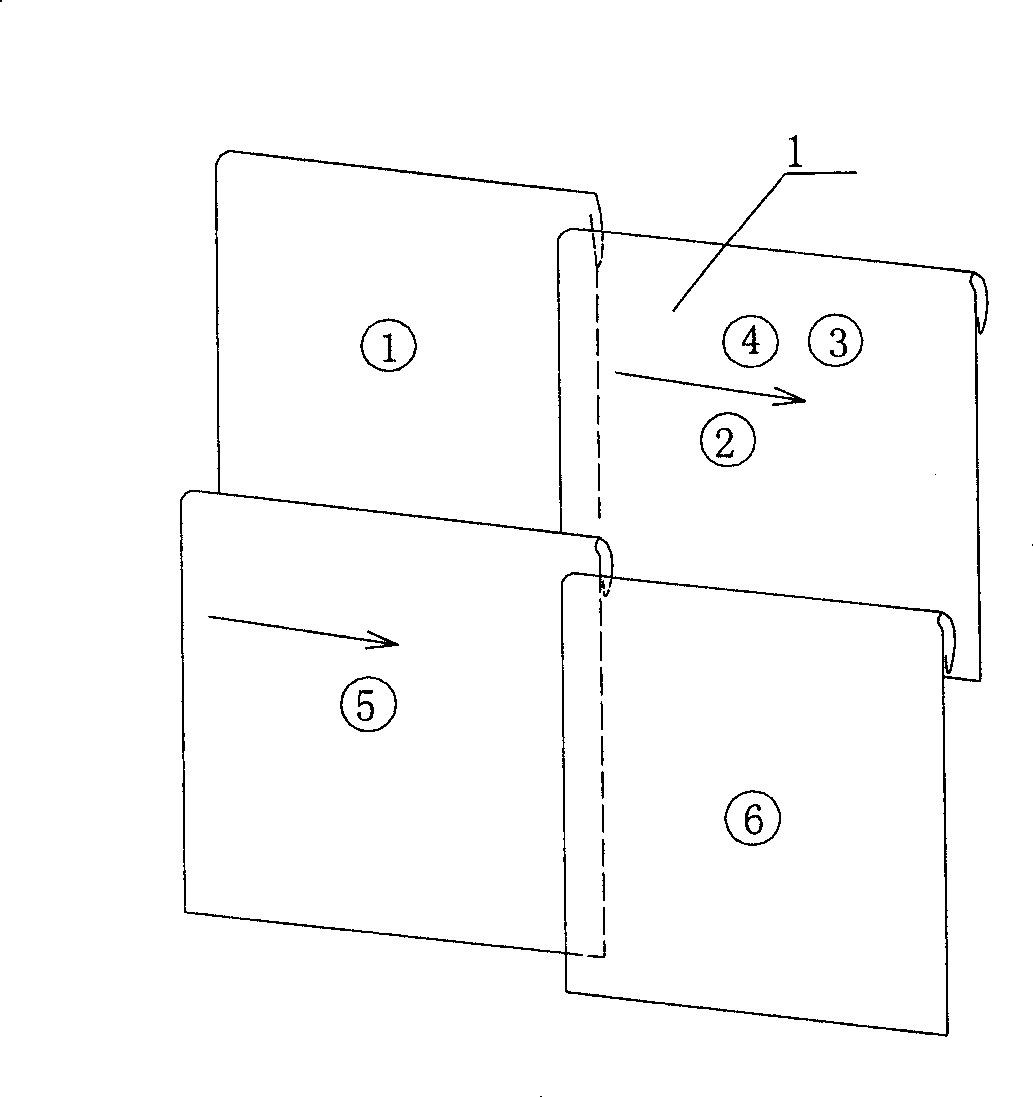

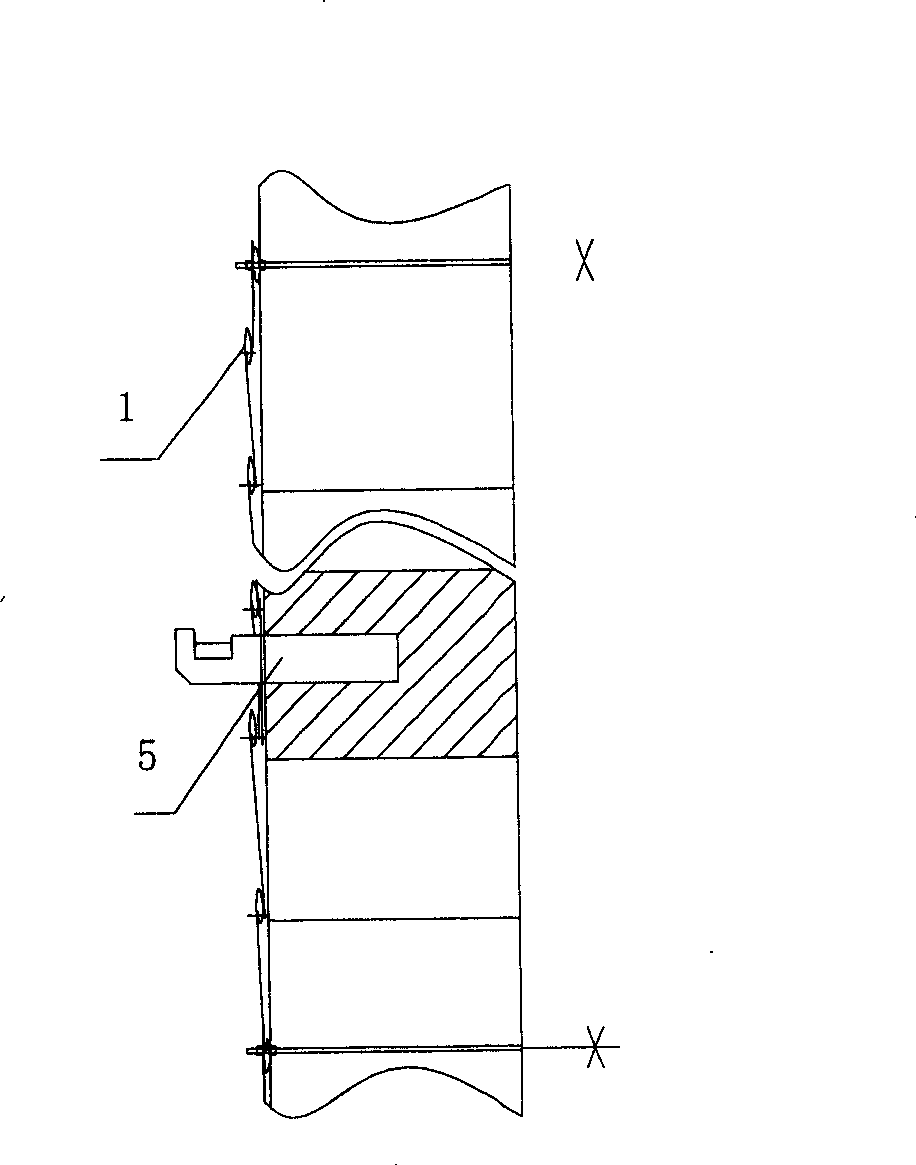

[0030] Such as Figure 1 to Figure 7 As shown, a method for sewing aluminum cloth for refractory fiber module structure furnace wall protection, including aluminum cloth 1, fixing needle 2, suture thread 3 and suture needle 4, the sewing method is implemented according to the following steps:

[0031] Step 1, single-piece sewing: In order to solve the problem of thermal shrinkage of the aluminum cloth 1, fold the left side and the upper side of the aluminum cloth 1 twice in the same direction to form a hem. The hem is first small and then large. According to the measured 1 Due to the size of heat shrinkage, the small hem is 5-15mm, and the large hem is 40-60mm. The hem and the body of the aluminum cloth 1 are overlapped and sewed together; A hole is opened at the corresponding position of the resistance band hanging brick 5 on the furnace wall, so that the resistance band hanging brick 5 can pass through the hole, and the four sides of the hole are folded to the outside of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com