Combined temperature increasing device and method by anaerobic degesting greenhouse

A solar water heater and anaerobic digestion technology, applied in anaerobic digestion treatment, biochemical equipment and methods, bioreactor/fermentation tank combination, etc., can solve the problems of high energy consumption and poor economy, and achieve energy saving, Efficient anaerobic digestion, the effect of improving efficiency and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

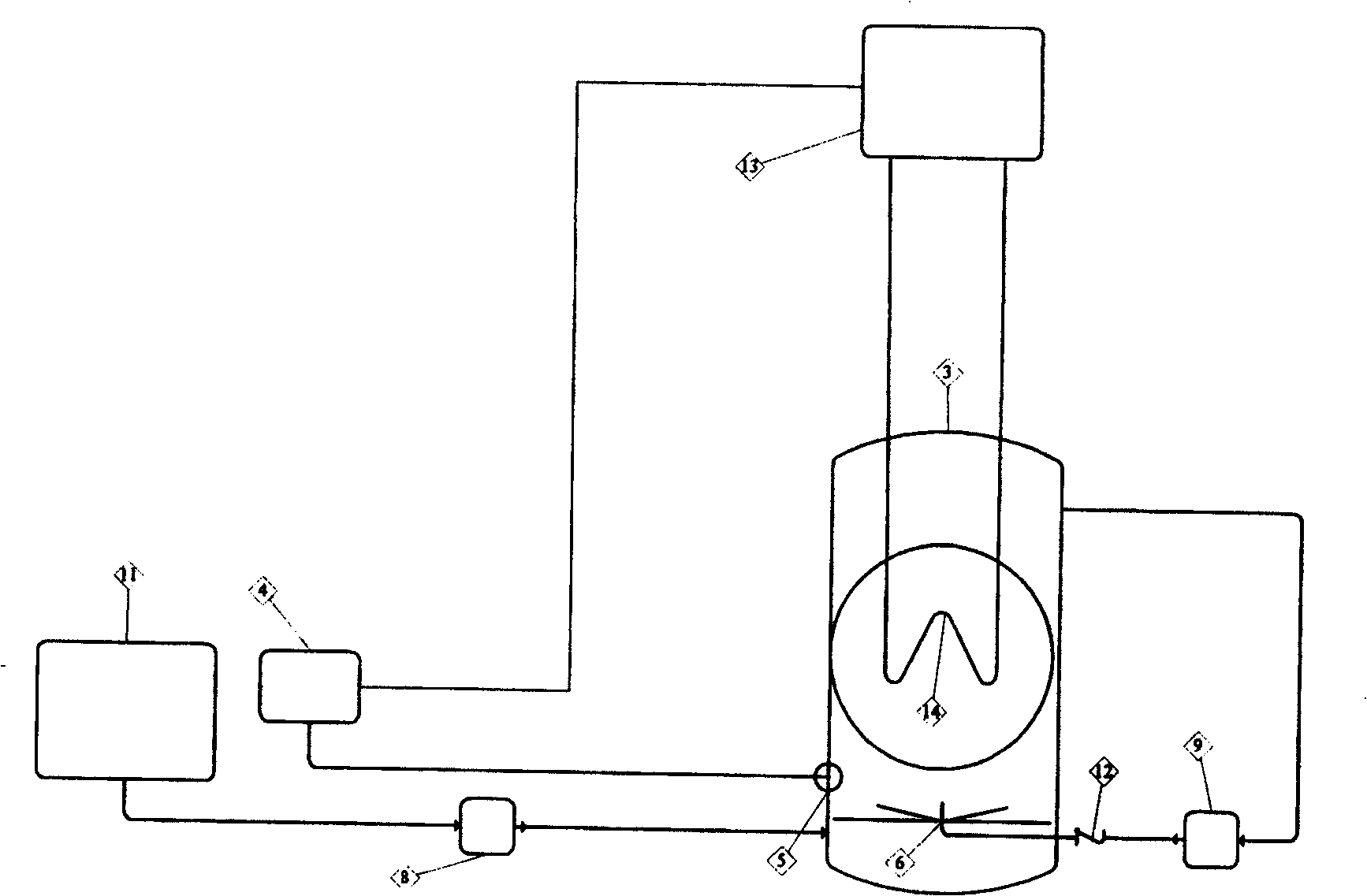

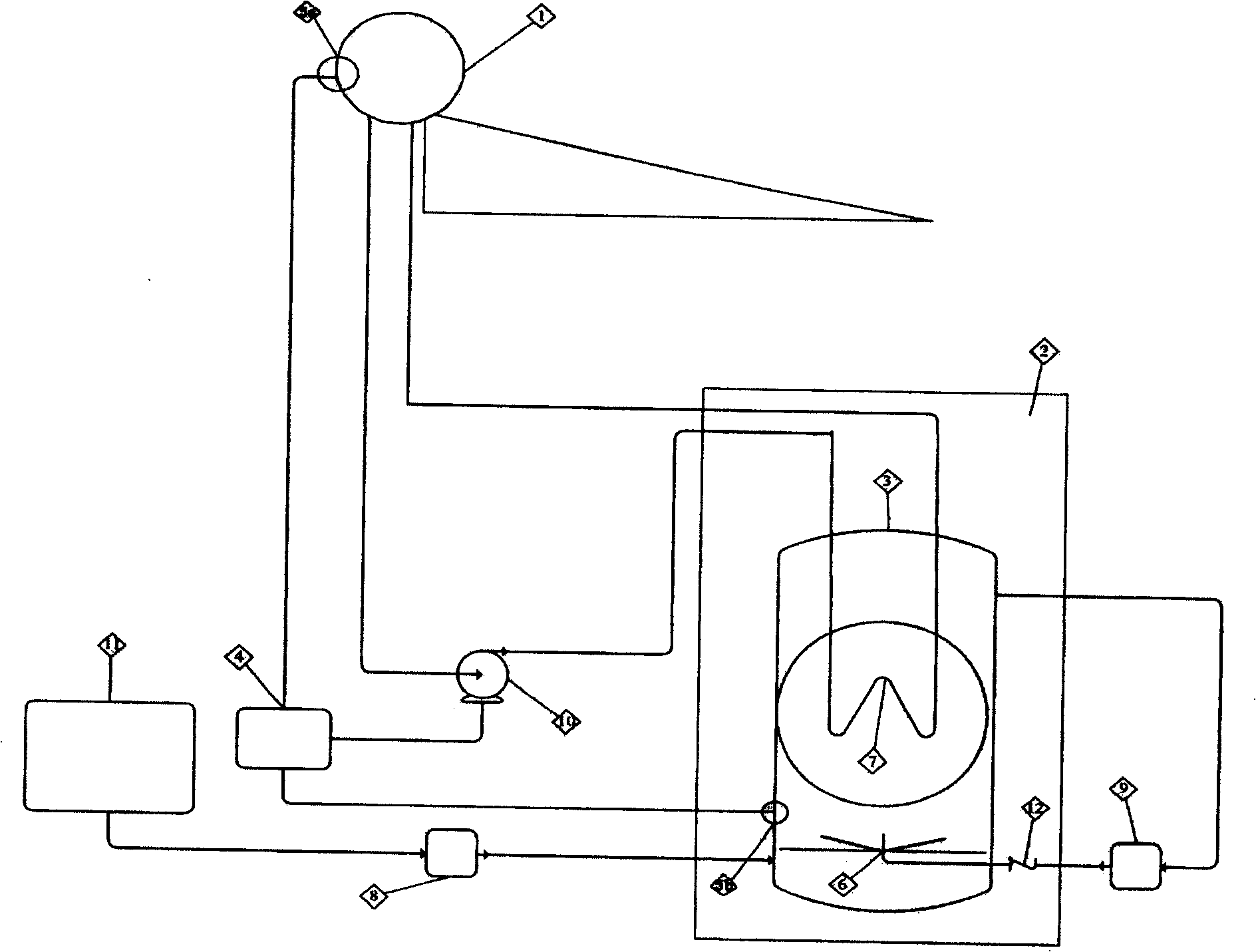

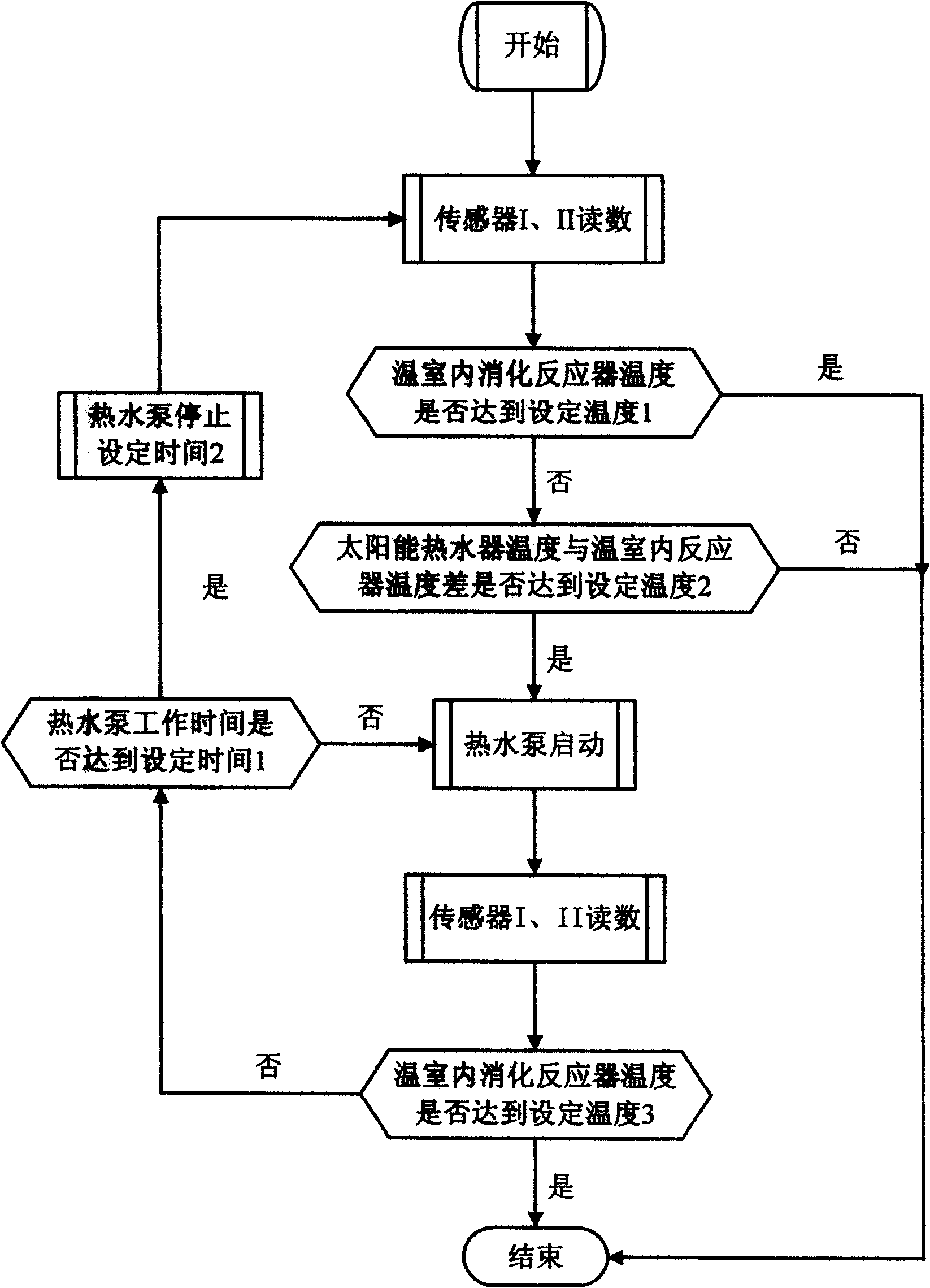

Method used

Image

Examples

example 1

[0030] Example 1: Example 1 is one of the embodiment examples of the present invention, but this patent is not limited thereto.

[0031] The total surface area of the greenhouse used in the present invention is 10.414m 2 . The solar water heater adopts a vacuum tube heat pipe water heater, has 24 lighting tubes, a power of 840W, and a water storage tank of 160 liters. The reactor is an anaerobic sequencing batch reactor (ASBR), which is made of carbon steel. The operating process parameters are: water inflow for 15 minutes, reaction for 20 hours, precipitation for 3.5 hours, and water outlet for 15 minutes; the operation time of a cycle is 24 hours. Use clean water to simulate anaerobic digestion of materials. Pneumatic stirring is used to pump the gas from the top of the reactor to the bottom once every hour through the air pump, and the gas diffuses into the water through the gas diffuser installed at the bottom to form bubbles and agitate. Temperature sensors are insta...

example 2

[0034] Example 2: Example 2 is one of the embodiment examples of the present invention, but this patent is not limited thereto.

[0035] In summer, a high-temperature anaerobic digestion simulation test is adopted, and the temperature is set at 50°C. Others are the same as in Example 1.

[0036] In a typical daily time change, the average temperature in the anaerobic digestion reactor is maintained at 33-36°C, with an average of 35.27°C, and the temperature increase effect is good. When the climatic conditions are good, the controlled temperature fully meets the temperature requirements of mesophilic high-efficiency anaerobic digestion. In a period of diurnal variation, although there were three obvious fluctuations in the ambient temperature due to climate reasons, the temperature in the anaerobic digestion reactor remained at 31-36°C, with an average of 34.05°C. This system has good control and adjustment ability for climate change in spring and autumn, and can keep the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com