Interpolymer paste resin and its preparing method

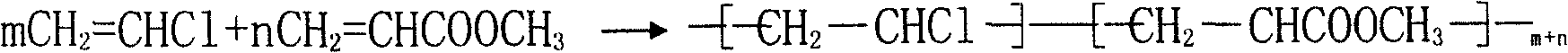

A vinyl acetate copolymerization paste resin and paste resin technology, which is applied in the field of preparing vinyl chloride-vinyl acetate copolymerization paste resin, and can solve the problems that PVC paste resin cannot be used in processing and application fields, cannot be formed into paste, and has irregular shapes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Feeding formula: vinyl chloride 95 (weight percent, the same below), vinyl acetate 5, pure water 120, sodium lauryl sulfate 1.2, C 12-26 Fatty alcohol 1.5, azobisisoheptanenitrile 0.02, toluene 0.1, ethylhexyl peroxydicarbonate 0.01.

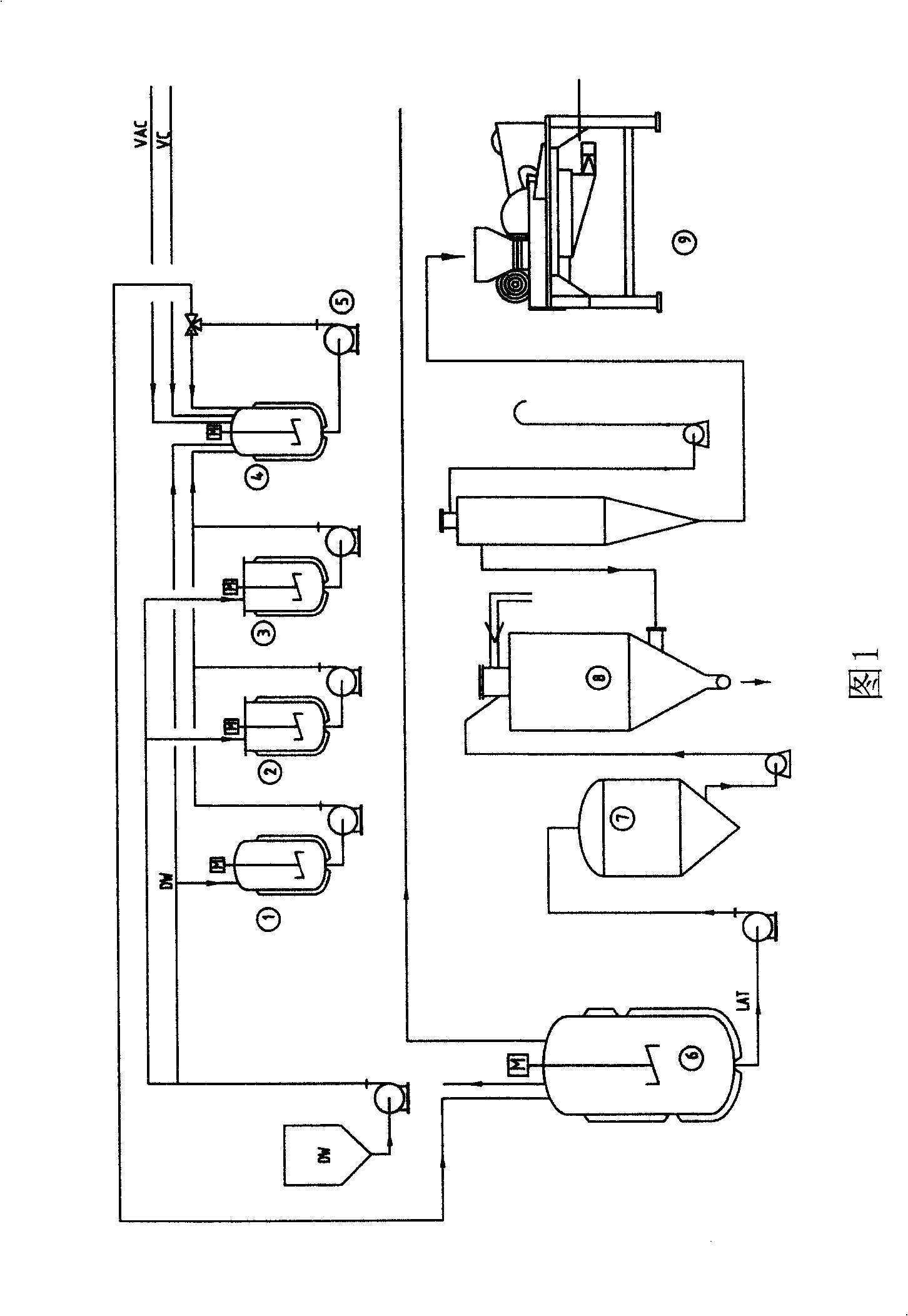

[0037] Sodium lauryl sulfate, C 12-26 Fatty alcohol and 10 parts of pure water (DW) were added to the emulsifier dissolving tank (equipment 3 in Figure 1) and stirred. Azobisisoheptanenitrile, toluene, and 5 parts of pure water were added to the initiator dissolving tank 1 (equipment 1 in FIG. 1 ) and stirred. Add ethylhexyl peroxydicarbonate and 5 parts of pure water to the initiator dissolving tank 2 (equipment 2 in FIG. 1 ) and stir. At the same time, add vinyl chloride (VC), vinyl acetate (VAC), pure water (100 parts), the dissolved emulsifier, and the initiator into the dispersion tank (equipment 4 in Figure 1), and turn on the dispersion pump (equipment 5 in Figure 1 ). ), while dispersing, feeding into the polymerization kettle ...

Embodiment 2

[0043] Follow the steps of Example 1.

[0044] Feeding formula: vinyl chloride 93 (weight percent, the same below), vinyl acetate 7, pure water 110, sodium dodecyl benzene sulfonate 1.2, C 12-26 Fatty alcohol 0.9, fatty acid 0.3, azobisisobutyronitrile 0.023, di-tert-butylcyclohexyl peroxydicarbonate 0.018.

[0045] Dispersion feeding time is 70min

[0046] Polymerization temperature 55℃

[0047] The conversion rate of vinyl chloride was 86.5%, and the conversion rate of vinyl acetate was 50.4%.

[0048] The analysis results of the finished product are as follows:

[0049] Product Quality Index

[0050]

Embodiment 3

[0052] Follow the steps of Example 1.

[0053] Feeding formula: vinyl chloride 86, vinyl acetate 14, pure water 100, sodium tetradecyl benzene sulfonate 0.9, C 14,2-26 Fatty alcohol 1.0, benzoyl peroxide 0.027, diisopropyl peroxydicarbonate 0.016.

[0054] Dispersion feeding time is 65min

[0055] Polymerization temperature 53℃

[0056] The conversion rate of vinyl chloride was 92.8%, and the conversion rate of vinyl acetate was 67%.

[0057] The analysis results of the finished product are as follows:

[0058] Product Quality Index

[0059]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com