Hidden arc welding used smelting solder

A technology for smelting flux and submerged arc welding, which is applied in the field of smelting flux for submerged arc welding, can solve problems such as non-horizontal fillet welding and flat welding application research, pitting, high-temperature cracks, etc., and achieve good welding slag peeling, welding slag Good peelability and high temperature crack resistance, good effect of welding slag peelability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

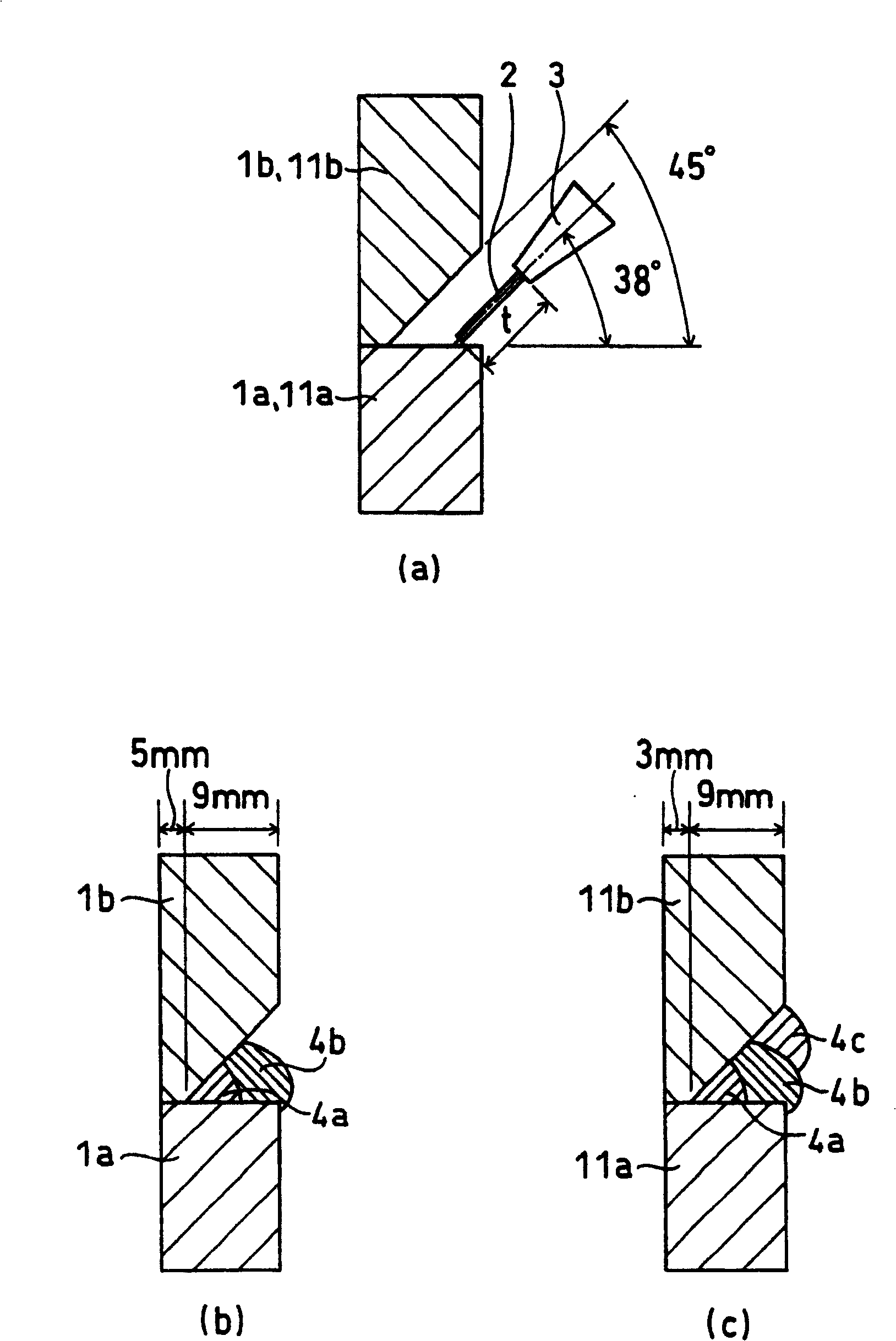

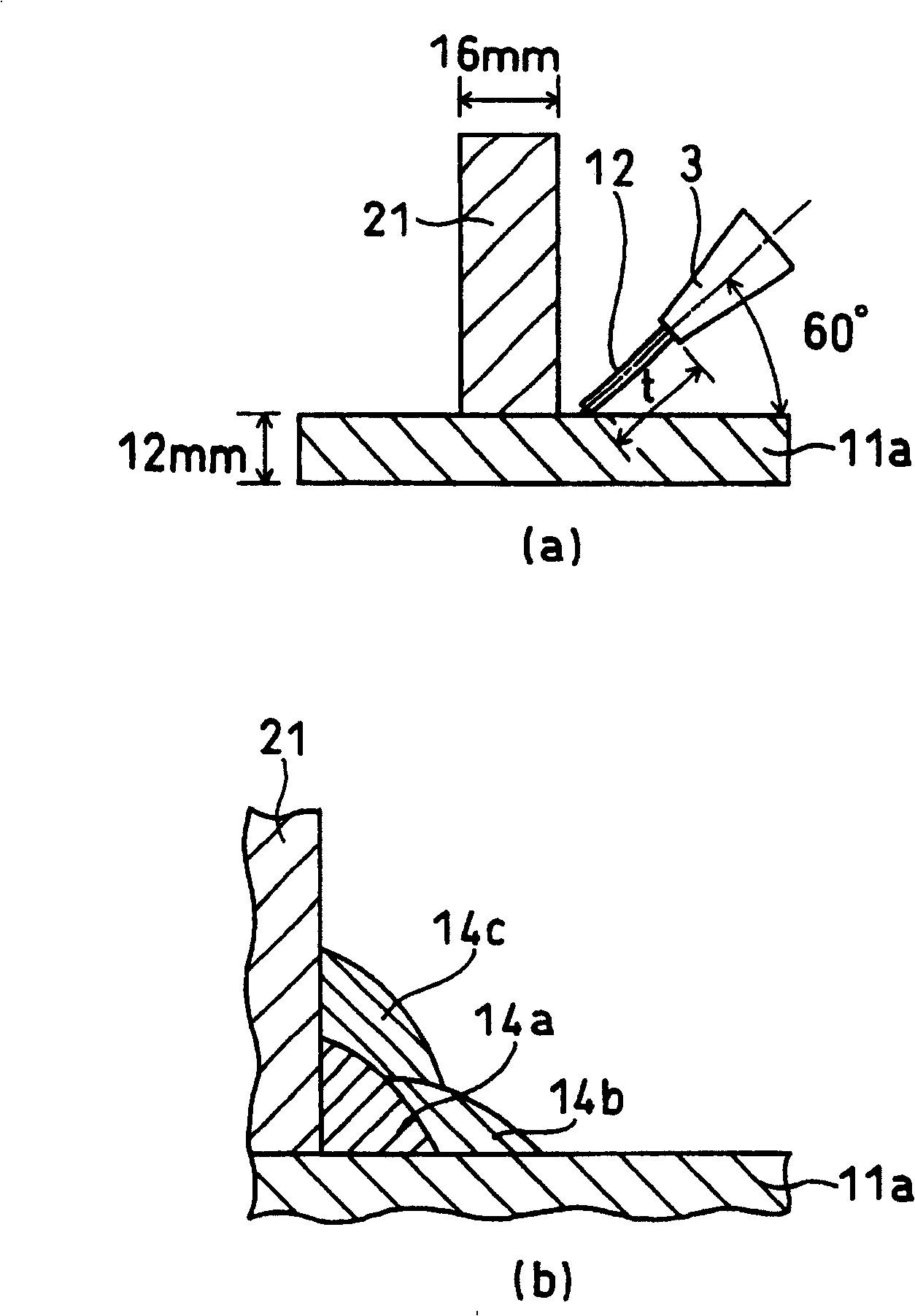

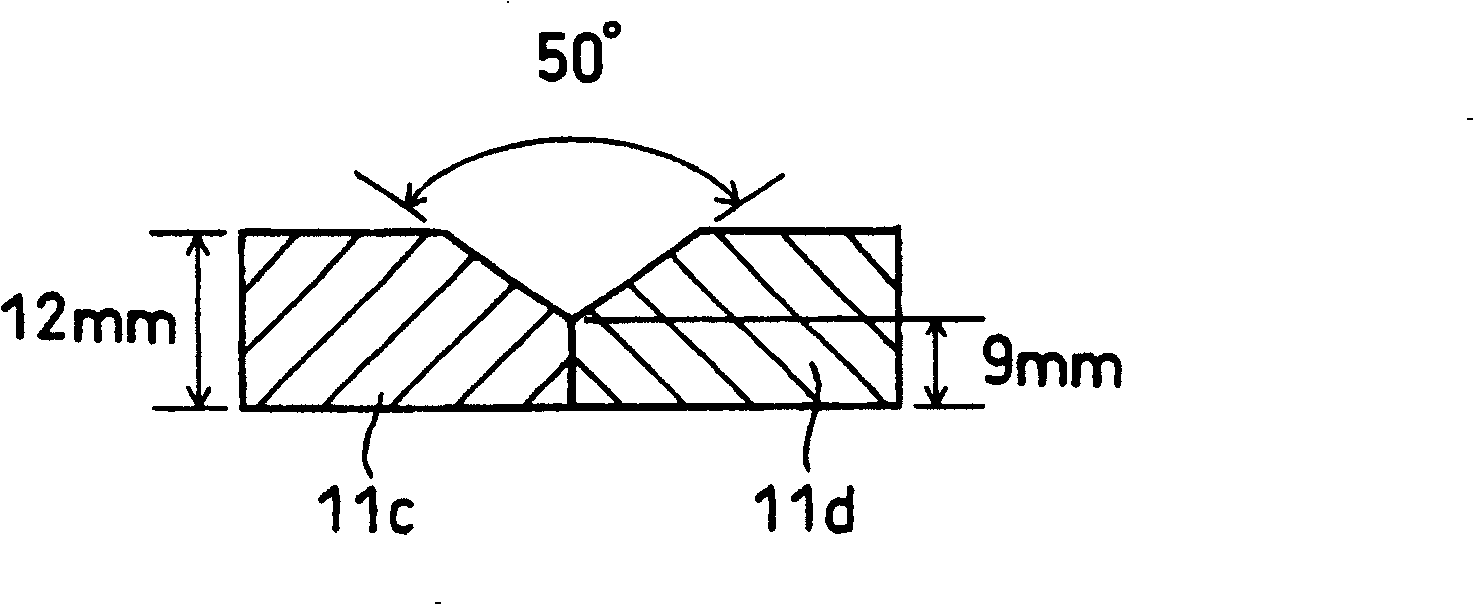

Image

Examples

Embodiment Construction

[0027] Hereinafter, such a flux according to an embodiment of the present invention will be specifically described. The flux of this embodiment is a melting flux used for submerged arc welding. Hereinafter, the reason for numerical limitation regarding the component composition of the flux of this embodiment is demonstrated.

[0028] SiO 2 : 10 to 40% by mass

[0029] SiO in flux 2 Acts as a slag forming agent to increase the viscosity of molten slag. In addition, there is an effect of improving the retention force of the bead during lateral welding and stabilizing the shape of the bead. However, when SiO 2 When the content is less than 10% by mass, the viscosity of the molten slag is insufficient, the bead shape becomes unstable, and weld flash and undercut occur. On the other hand, if SiO 2 When the content exceeds 40% by mass, the viscosity of the molten slag becomes too high, the detachability of the slag decreases, and pitting and inclusion of slag occur. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com