Rail sensor

A sensor and track technology, applied in the field of sensors, can solve problems such as poor wear resistance, achieve the effects of improving service life, easy and convenient maintenance, and solving poor wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

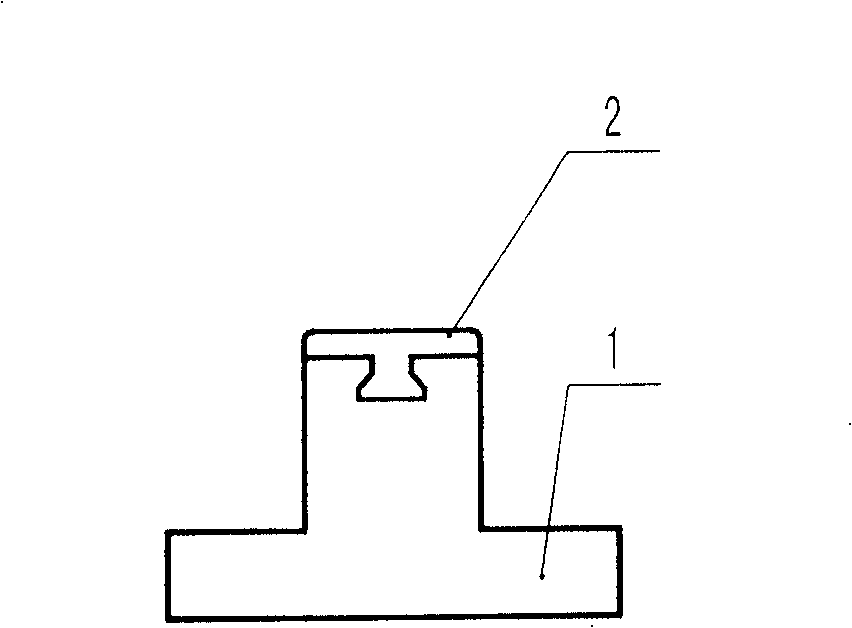

[0014] Embodiment 1: as figure 1 The socket socket 3 and the socket tongue 4 of the present invention are H-shaped;

Embodiment 2

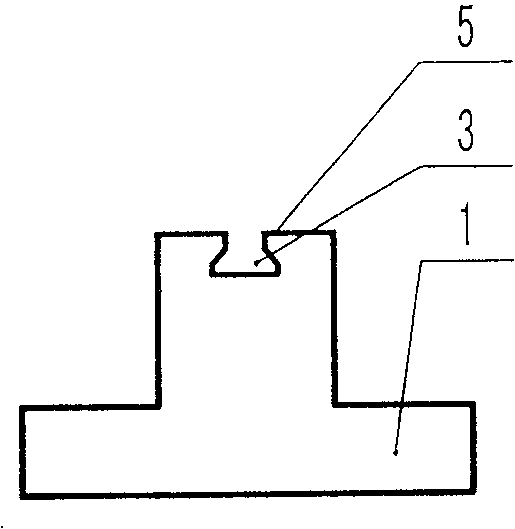

[0015] Embodiment 2: The socket socket 3 and the socket tongue 4 of the present invention are H-shaped, and are wedge-shaped along the longitudinal direction of the track sensor, so that the socket socket and the connector are more closely matched.

Embodiment 3

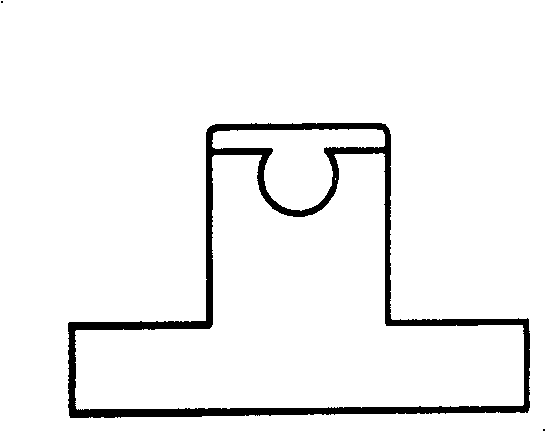

[0016] Embodiment 3: as Figure 4 The socket socket 3 and the socket tongue 4 of the present invention are dovetail-shaped;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com