Method for fabricating electric cold light sheet without joint shadow, and electric cold light sheet

A production method and seamless technology, applied in the direction of electroluminescent light source, electric light source, light source, etc., can solve the problem of losing the integrity of the pattern, and achieve the effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

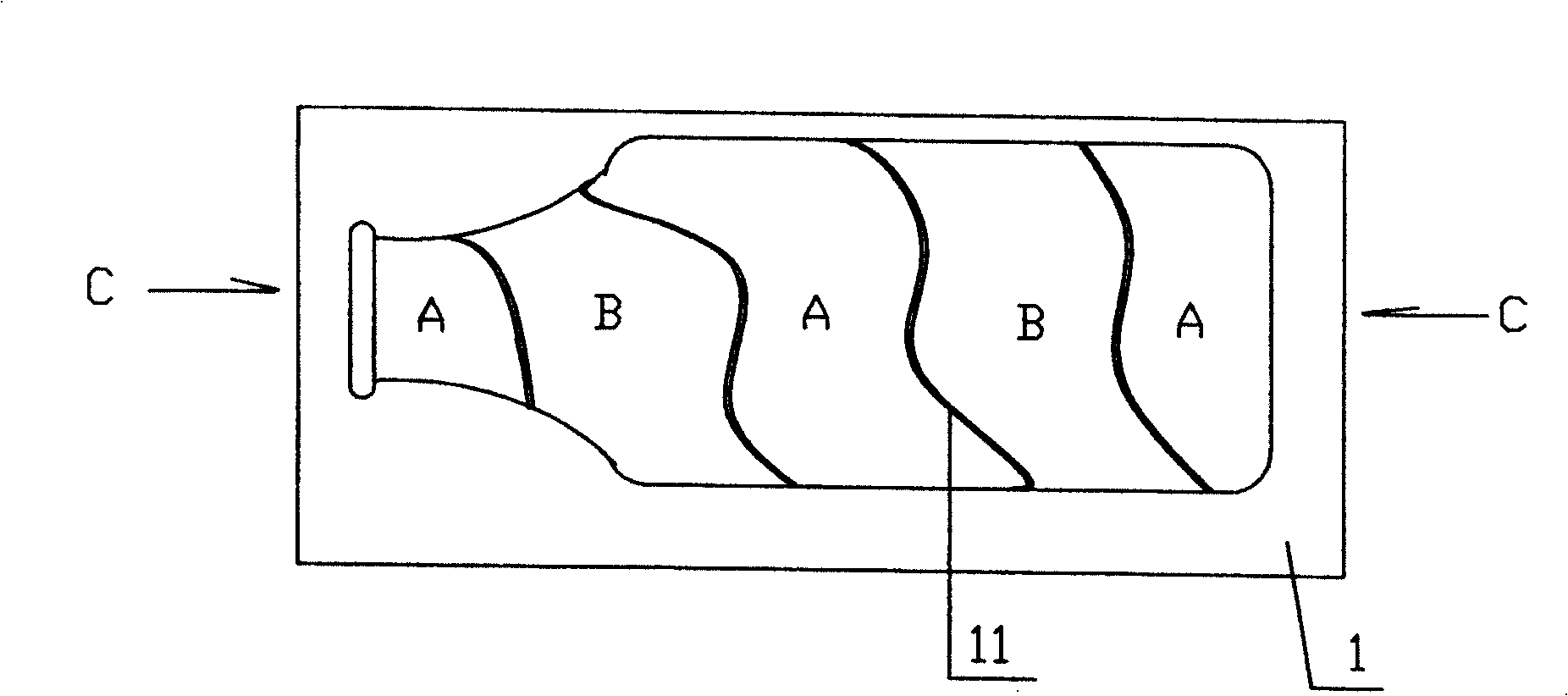

[0025] Such as figure 1 : When general electroluminescent products run lights in sections, because multiple light-emitting blocks must be arranged on the line, the conductive layer between the blocks must be separated, so there will be insulation between the blocks The existence of the gap 11 causes shadows to be generated between the two groups of different pattern blocks A and B in the electroluminescent light-emitting area.

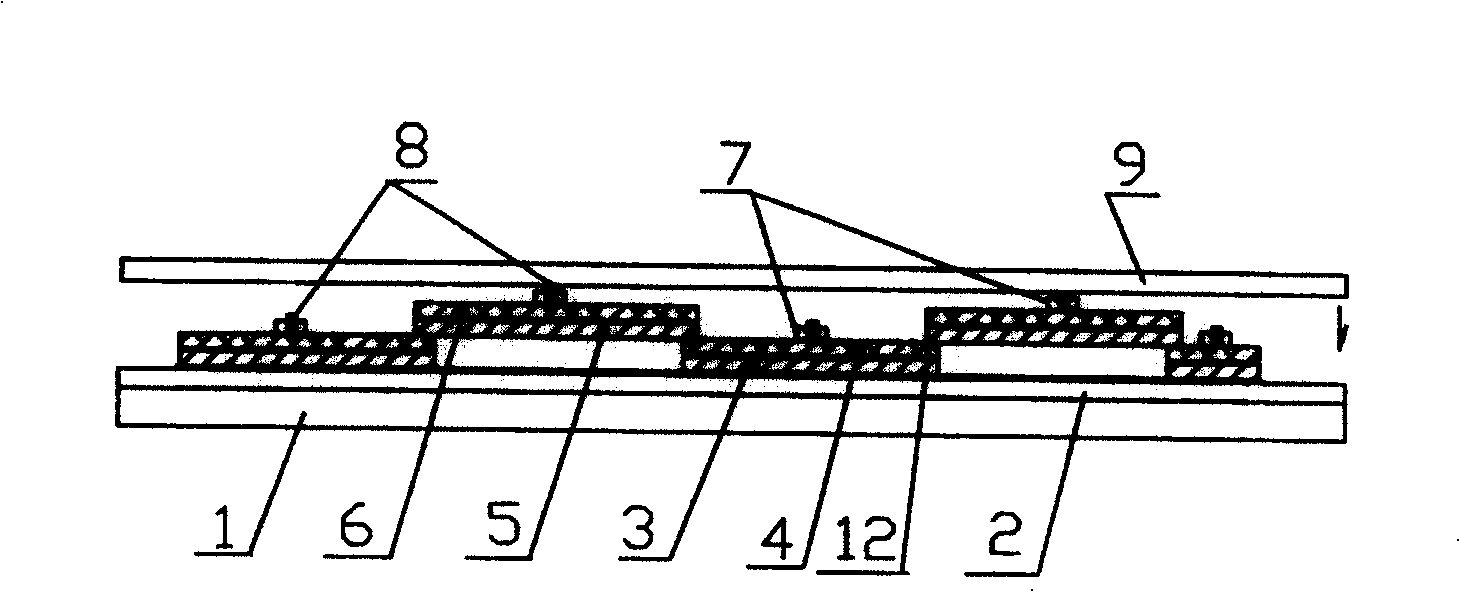

[0026] Such as figure 2 : The present invention makes the light-emitting gap of electroluminescence into a light-emitting overlapping region 12, so that the shadow between the light-emitting regions A and B of electroluminescence is reduced, or even completely eliminated.

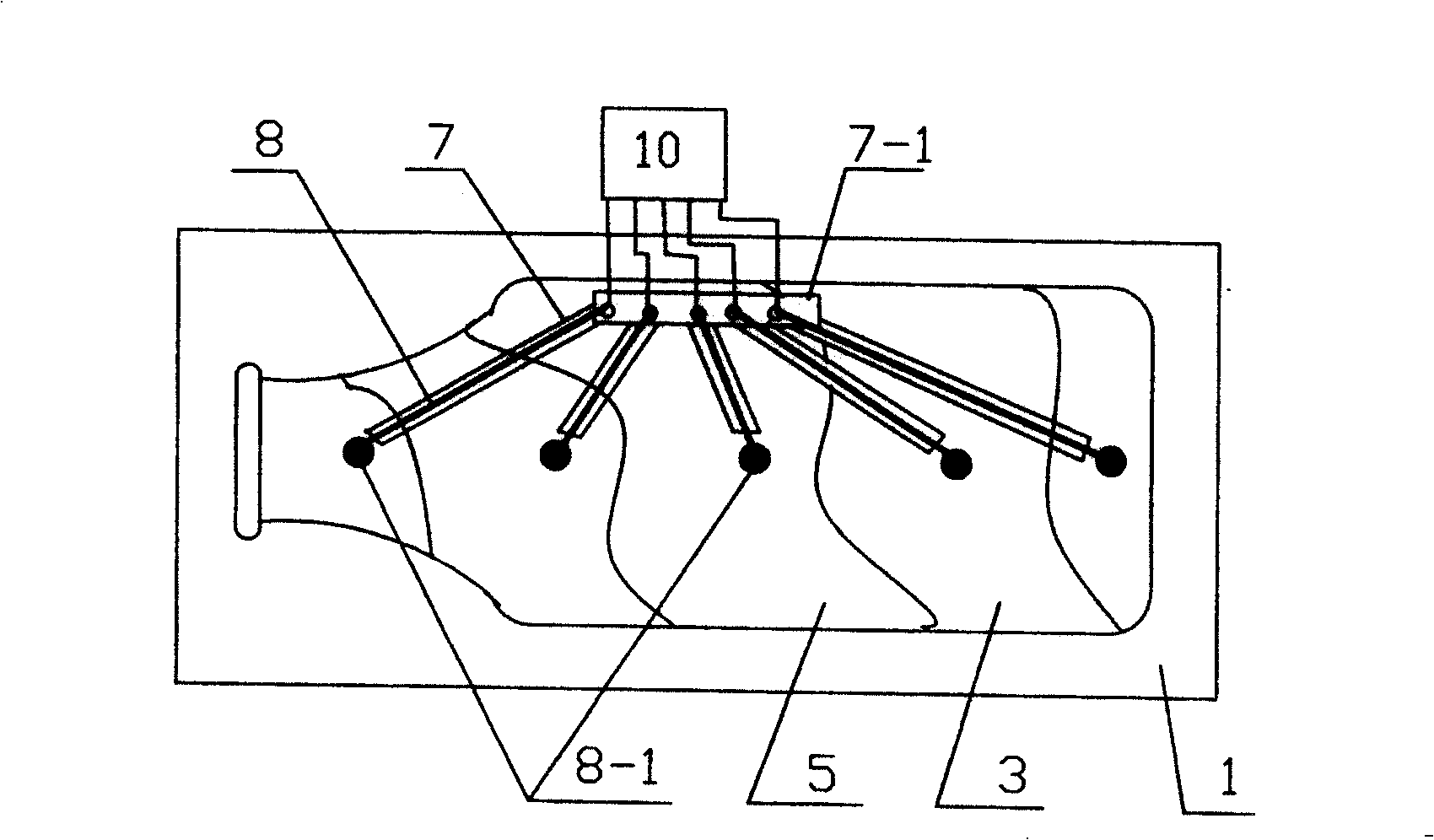

[0027] The preparation method of the electroluminescent sheet of seamless shadow of the present invention is as follows:

[0028] A) printing fluorescent layer 2 on transparent conductive film 1;

[0029] B) Divide the pattern blocks on the fluorescent layer into two groups A an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com