Drill hole depth identification through ray

A technology for drilling tools and drilling depth, which is applied in the direction of drilling/drilling equipment, manufacturing tools, portable mobile devices, etc., and can solve problems such as surface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

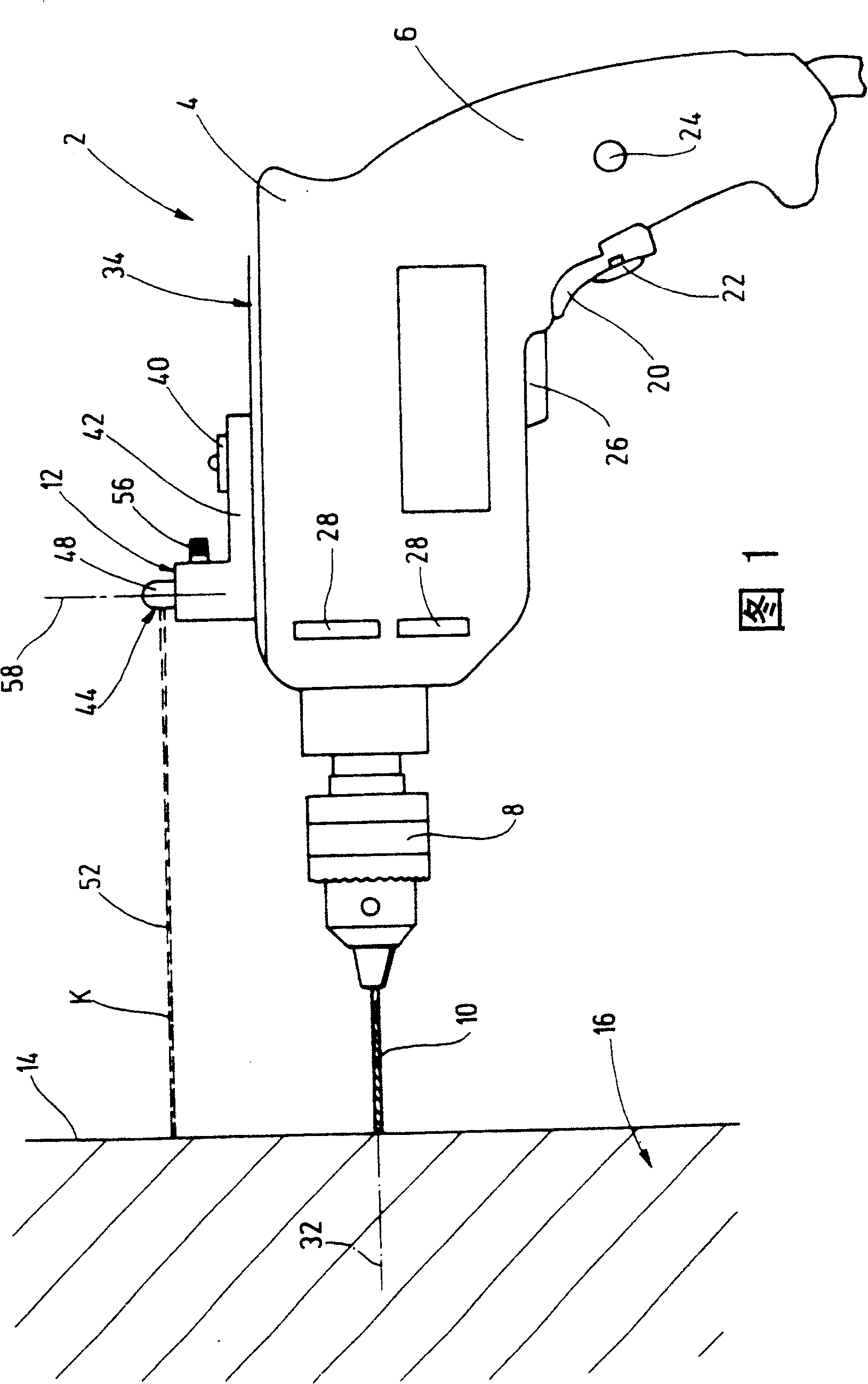

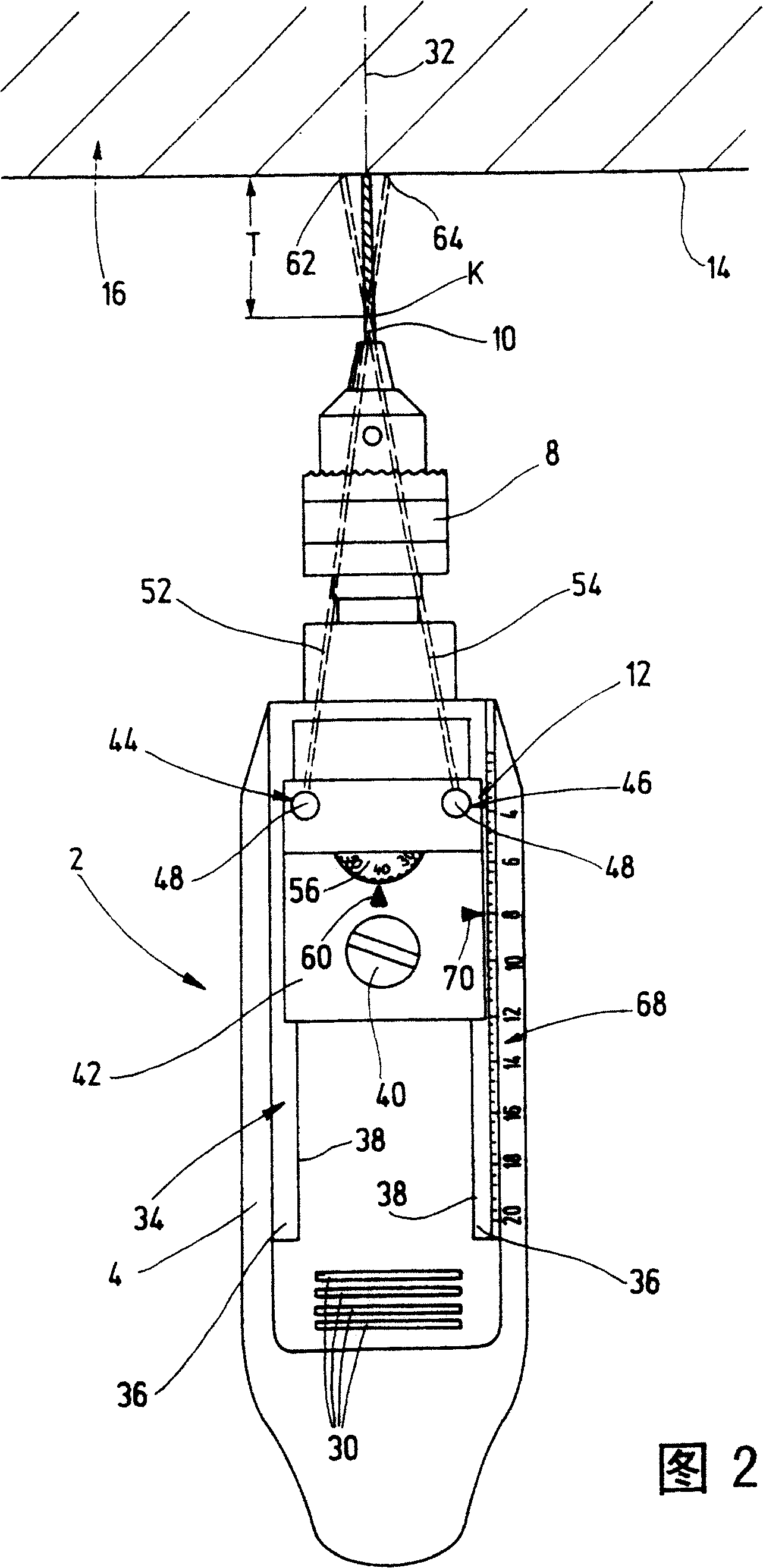

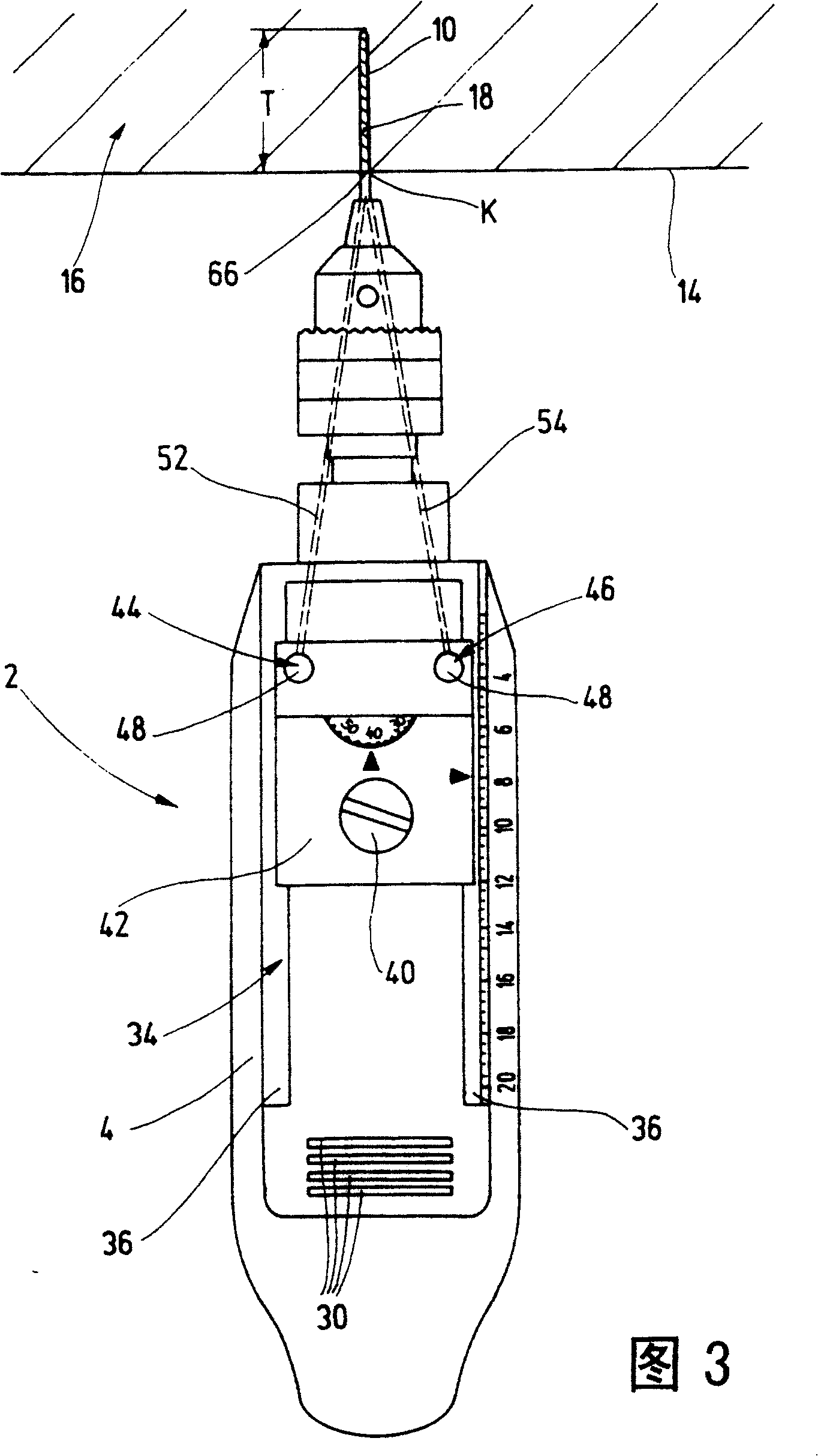

[0024] The drilling machine 2 shown in the accompanying drawings mainly consists of a housing 4 with a handle 6, a drill chuck 8 protruding from the housing 4 for clamping a drill 10 or other drilling tools, and a The device 12 that is mounted detachably on the surface of the housing 4 consists of a contactless determination of a borehole 18 to be drilled on a wall 16 or other flat surface 14 of a workpiece by means of a drilling machine 2 and a drill bit 10 The preset drilling depth T is reached in the middle (Fig. 3).

[0025] Like most drilling machines commonly seen in the market, an on / off switch 20 is provided on the handle 6 of the housing 4, and an on / off switch 20 integrated in the on / off switch 20 is used to adjust the drill chuck. An adjustment wheel 22 for the rotational speed of the disc 8 , a determination button 24 for continuous operation of the drilling machine 2 , and a switch 26 for changing the direction of rotation of the drill chuck 8 . The housing 4 sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com