Method for repairing thin-film transistor array substrate and thin film removing method

A technology of thin film transistors and array substrates, which is applied in the repair of thin film transistor array substrates and the removal of thin films. It can solve the problems of affecting display quality and increasing the number of dark spots on the panel, so as to improve the process yield and ensure normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

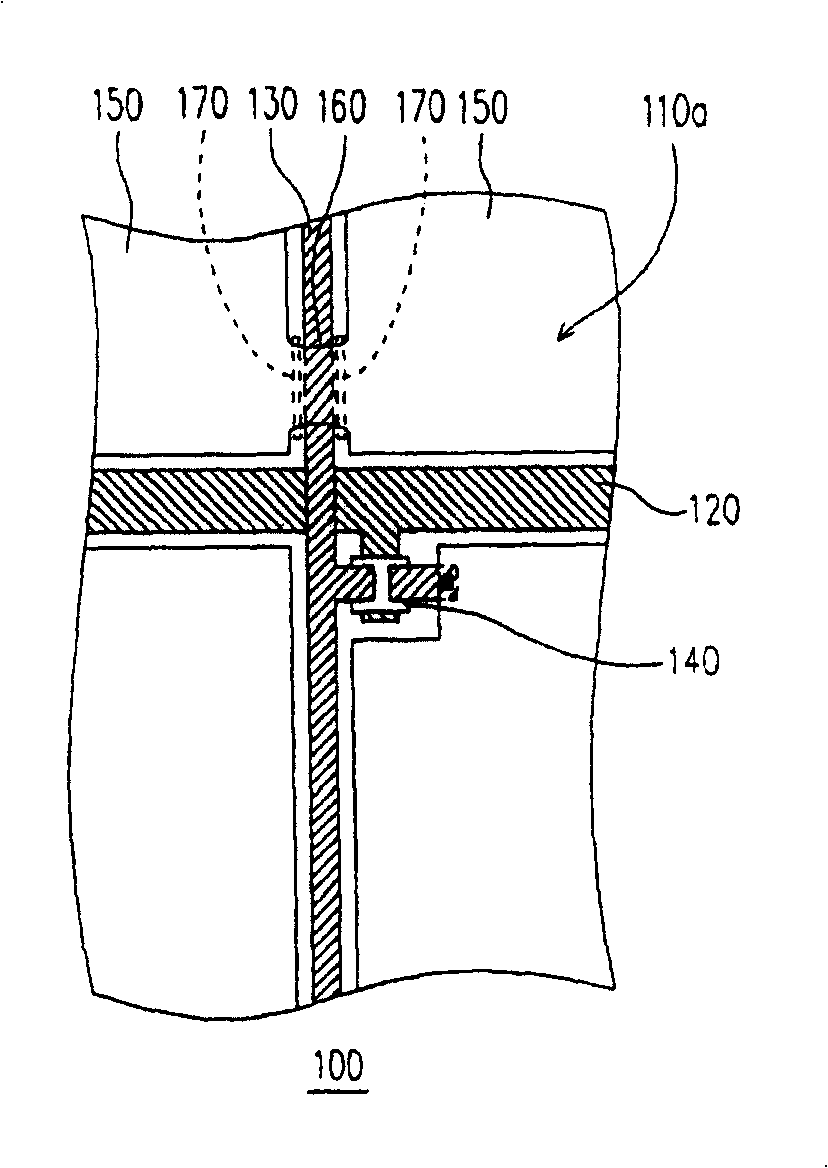

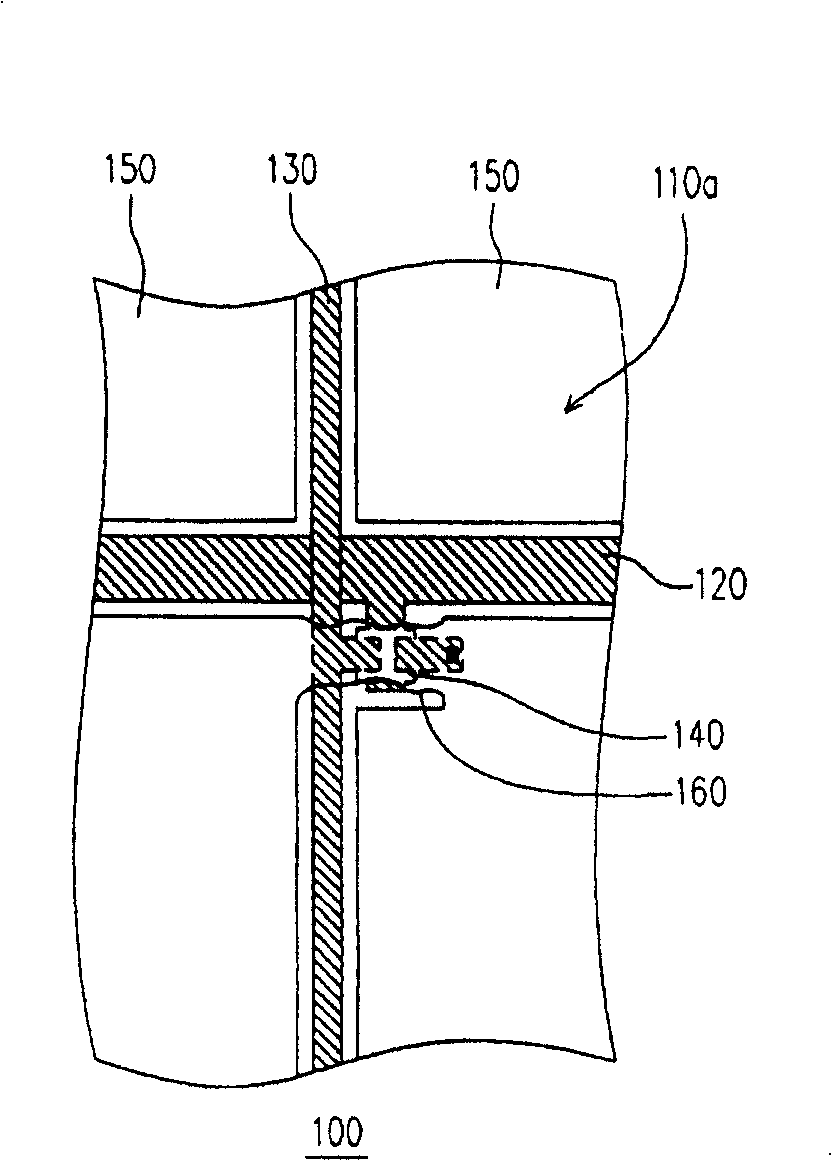

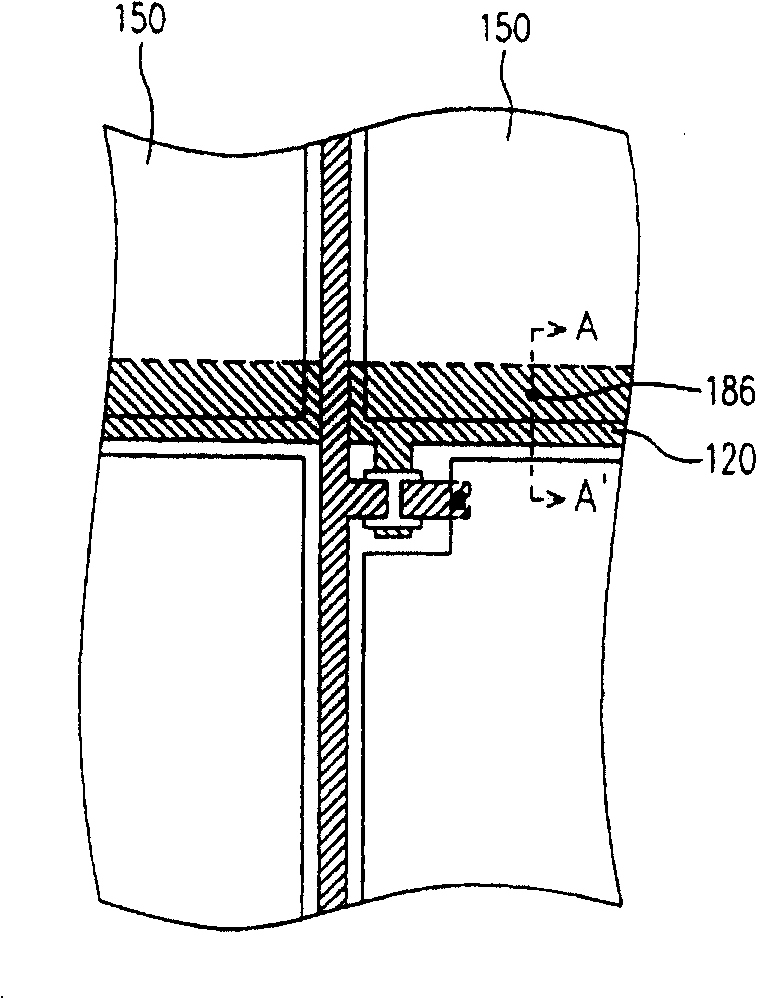

[0030] Please refer to figure 1 , which shows a schematic diagram of a thin film transistor array substrate according to a preferred embodiment of the present invention. The thin film transistor array substrate 100 includes, for example, a substrate 110 (shown in Figure 3B Middle), a plurality of scanning lines 120 , a plurality of data lines 130 , a plurality of thin film transistors 140 and a plurality of pixel electrodes 150 . Wherein, the scan wires 120 and the data wires 130 are respectively disposed on the substrate 110, and a plurality of pixel regions 110a are divided on the substrate. The thin film transistor 140 is correspondingly disposed in the pixel area 110 a and driven by the scan wiring 120 and the data wiring 130 . In addition, the pixel electrode 150 is correspondingly disposed in the pixel region 110 a and is electrically connected to the corresponding thin film transistor 140 , and the material of the pixel electrode 150 is, for example, a transparent co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com