Rotary type displacement compressor

A compressor and rib-type technology, applied in the field of rotary volumetric compressors, to achieve the effects of convenient installation and fixation, low manufacturing cost and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

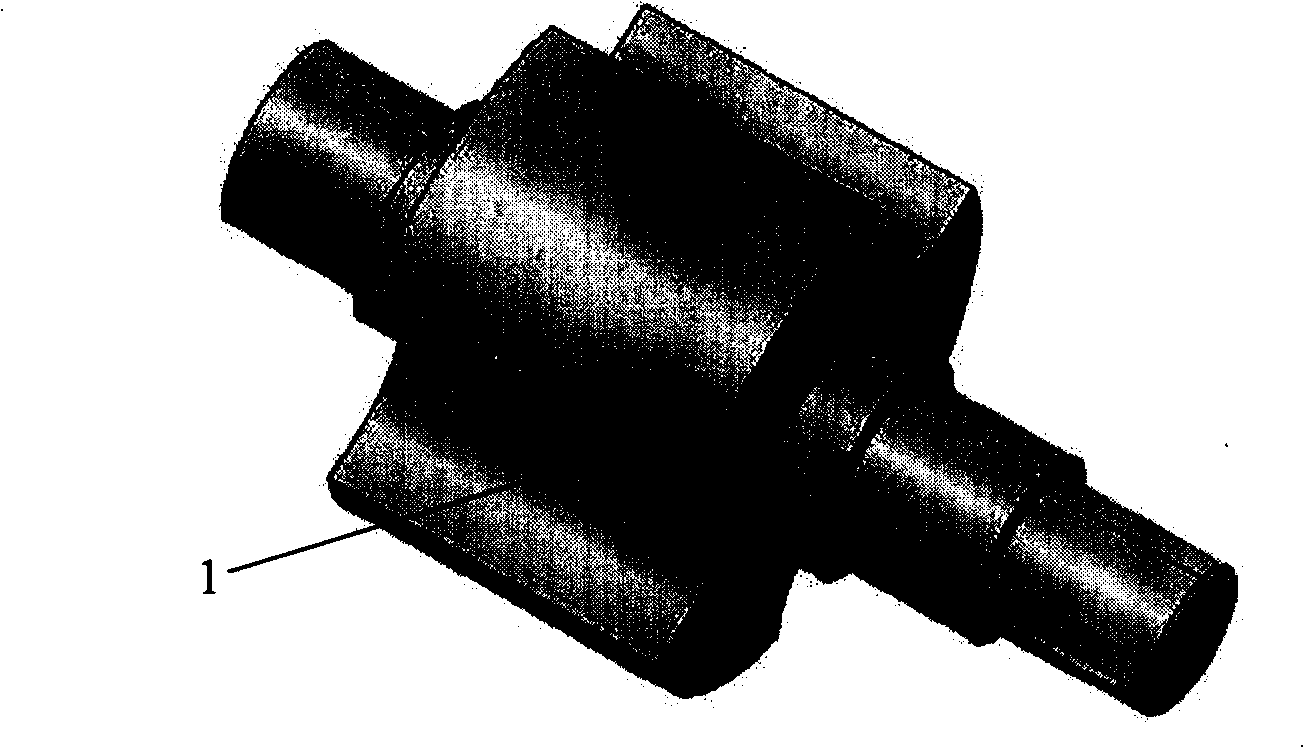

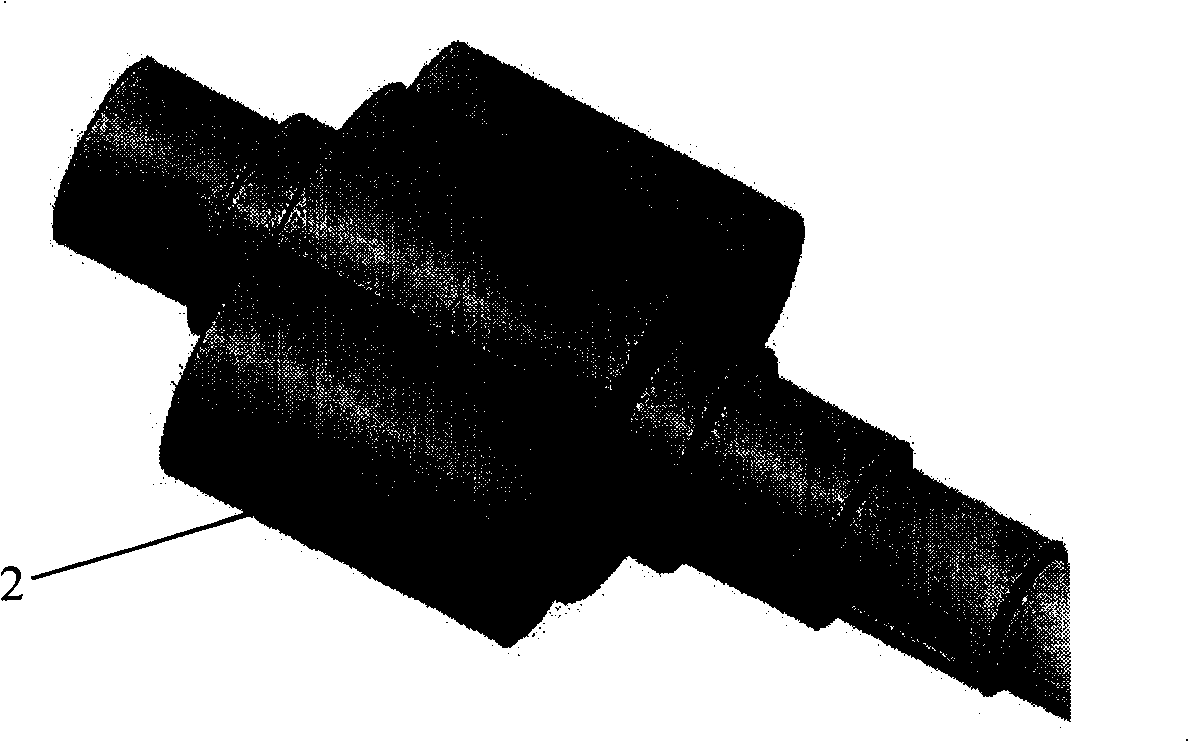

[0014] figure 1 The female rotor shown is provided with three grooved profiles 1, figure 2 The shown male rotor is provided with two ribbed profiles 2 . It can be seen from the figure that the concave and convex profiles of the female and male rotors are formed by expanding laterally along the axial direction of the female and male rotors respectively, which are always parallel to the axial direction of the female and male rotors and not along the The direction of the rotor axis is reversed.

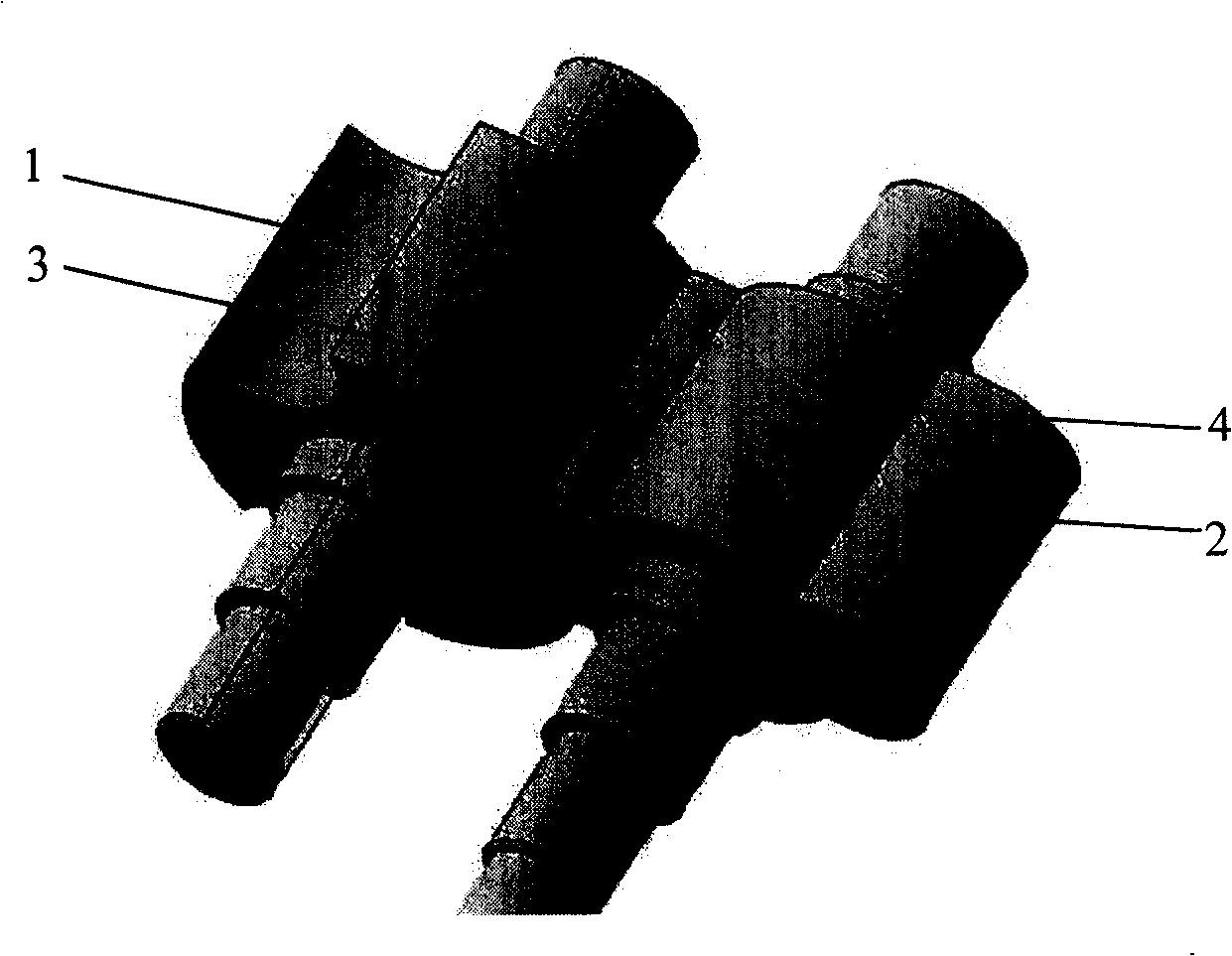

[0015] image 3 It is a three-dimensional rendering of a pair of male and female rotors with a ratio of 2 / 3 of the number of rib-type surfaces to the number of groove-type surfaces assembled together according to the relationship of working positions.

[0016] exist Figure 4 In the illustrated embodiment, the figure 1 Shown female rotor 3 with figure 2 Shown male rotor 4, according to image 3 The working position relationship shown is installed and fixed in the "∞"-shaped cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com