Levelling and hanging thermal-insulating composite decoration panel and construction method thereof

A technology of thermal insulation composite and decorative panels, applied in building components, building materials, buildings, etc., can solve the problems of poor decoration and inability to guarantee the quality of on-site construction, and achieve the effect of expanding the scope, wide decorative effect, and convenient and practical overall installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Structure and construction of the present invention are described as follows in conjunction with accompanying drawing:

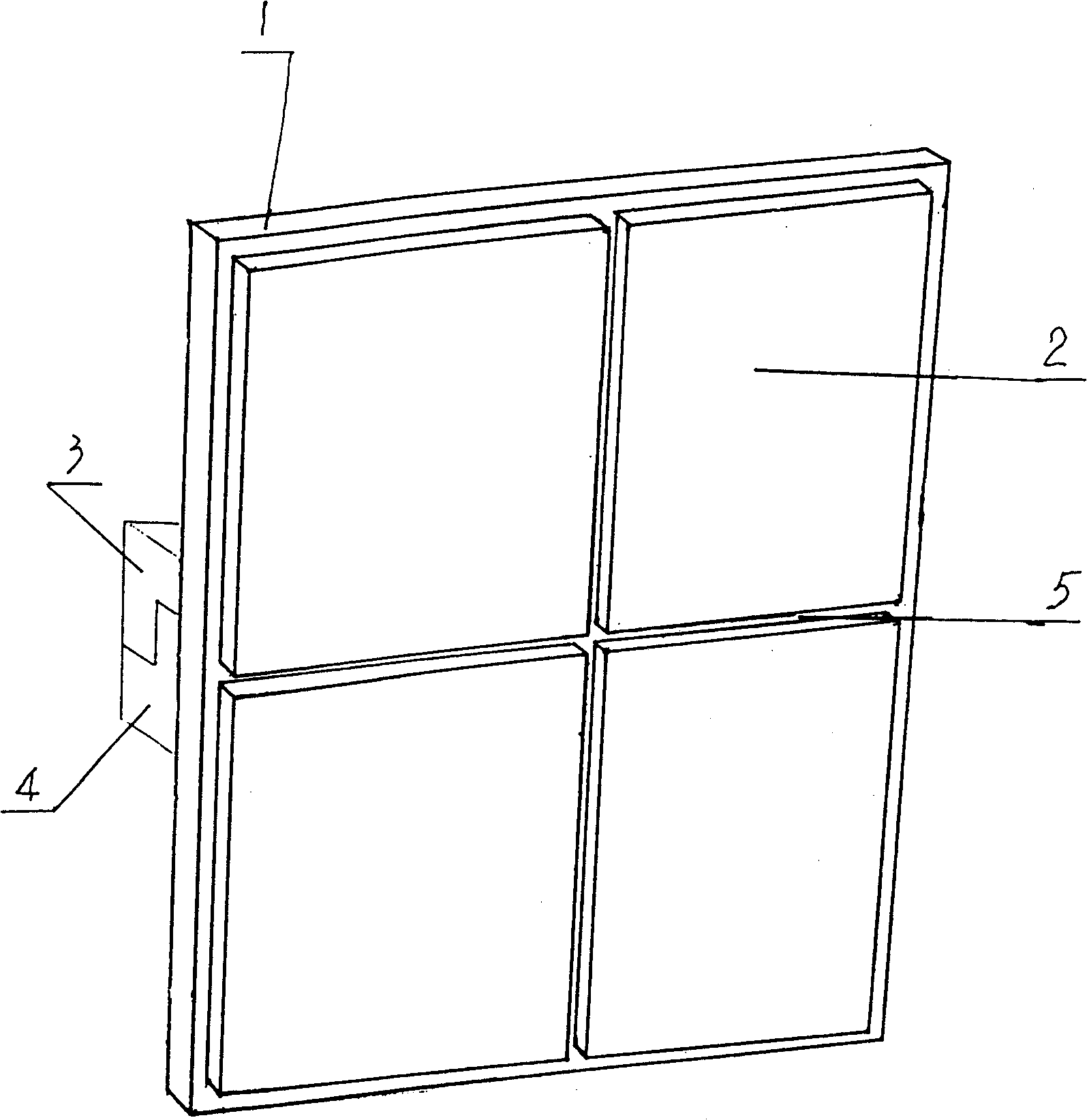

[0025] See figure 1 , a kind of heat preservation composite decorative board that can be leveled and articulated, the foamed plastic board 1 is the inner board, the decorative surface 2 of the reinforcing layer is the panel, the inner surface of the foamed plastic board 1 is provided with a hooking part 3, and the hooking part 3 The matching leveling and fixing hook 4 that can be fixed on the building wall. The hook 3 is a convex hook. The leveling and fixing hook 4 is a groove hooking. The decorative surface 2 of the reinforcing layer is provided with a plate surface reticular groove 5 . The centerline of the mesh plate surface groove 5 and the centerline of the mesh-shaped hanging part 3 are on a horizontal plane.

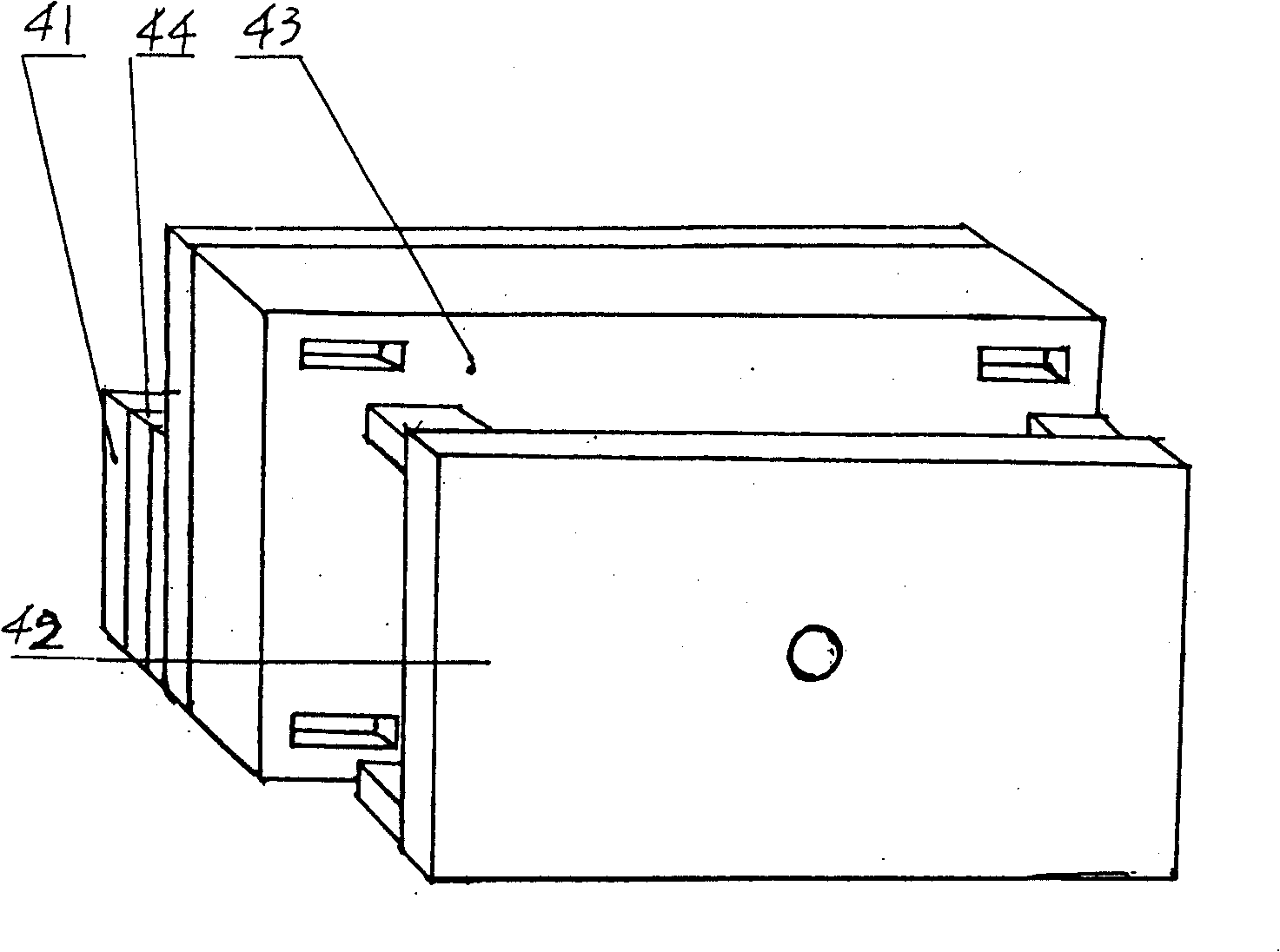

[0026] See figure 2 , the leveling and fixing hook 4 that can be leveled and articulated to the thermal insulation composite deco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com