Low temperature construction method for bridge support grouting

A bridge support and construction method technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of slow bridge erection, failure to erect, and rapid loss of fluidity, etc., to save energy and time, heat Fast speed, reduce the effect of water vapor evaporation

Inactive Publication Date: 2008-11-12

北京建工华创工程技术有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Since the bridge and the bridge piers are mainly connected by supports, the pouring quality will directly determine the safety and service life of the bridge, and the solidification characteristics of concrete determine that this important process will inevitably be affected by the environment. When constructing under high temperature conditions, the fluidity of the slurry will be lost quickly. Generally, when the temperature is higher than 35°C, it is necessary to take cooling measures, such as shading, watering, preparing ice water as mixing water, etc., which are relatively easy Solve, when constructing under low temperature conditions, especially negative temperature conditions, the bridge erection speed is often slow or cannot be erected, mainly because there is no effective low temperature construction method, and most of the current heating antifreeze processes use electric blankets to However, due to the low power of the general electric blanket, it is easy to absorb water vapor and dissipate heat quickly with the outside world, so it can only be heated by convection or radiation, which is inconvenient to heat the steel backing plate of the bridge support. Moreover, the heating part is limited, and the overall strength and frost resistance of each part of the anchor mortar cannot be guaranteed, which will bury a huge hidden danger to the overall safety of the bridge.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

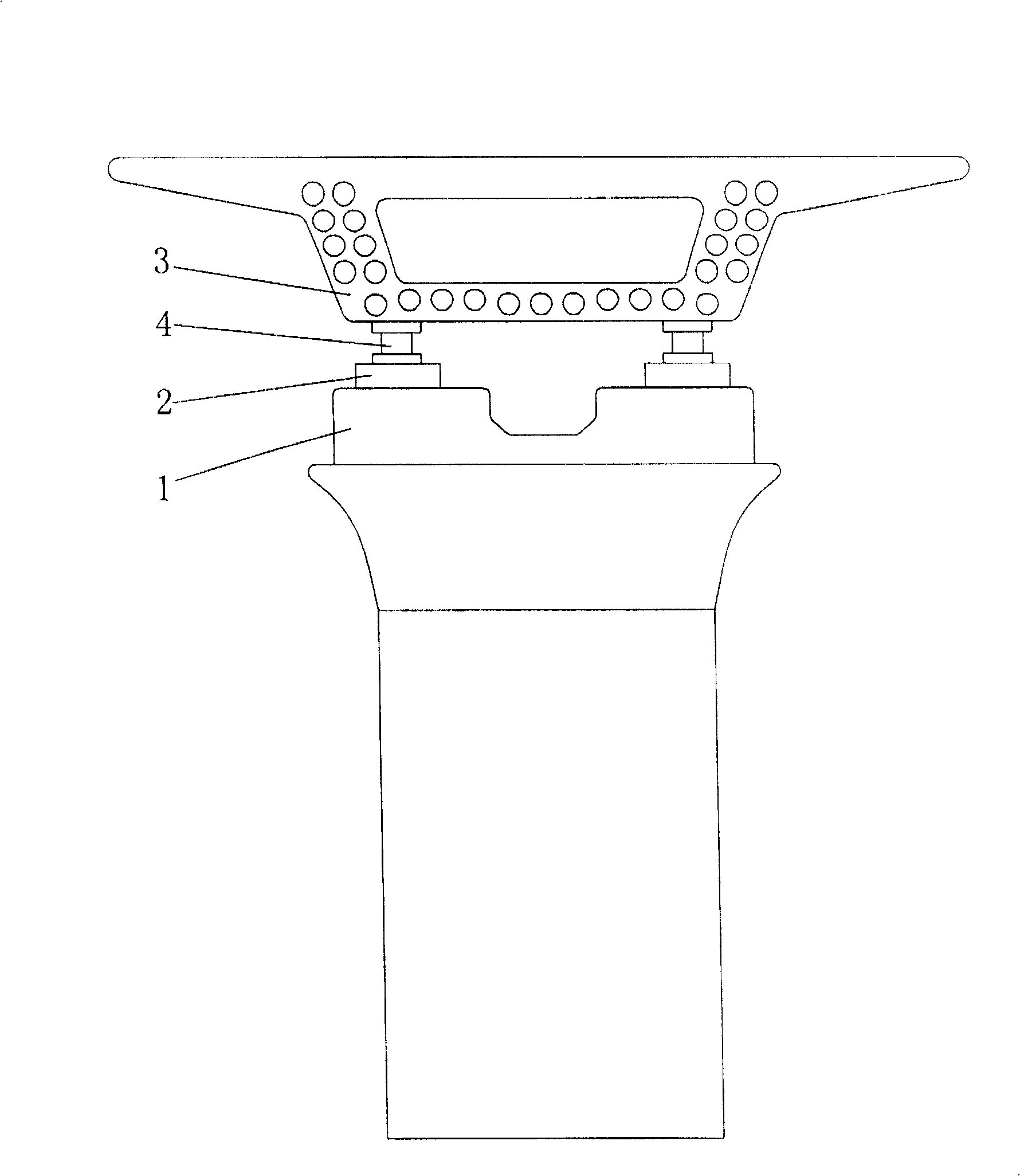

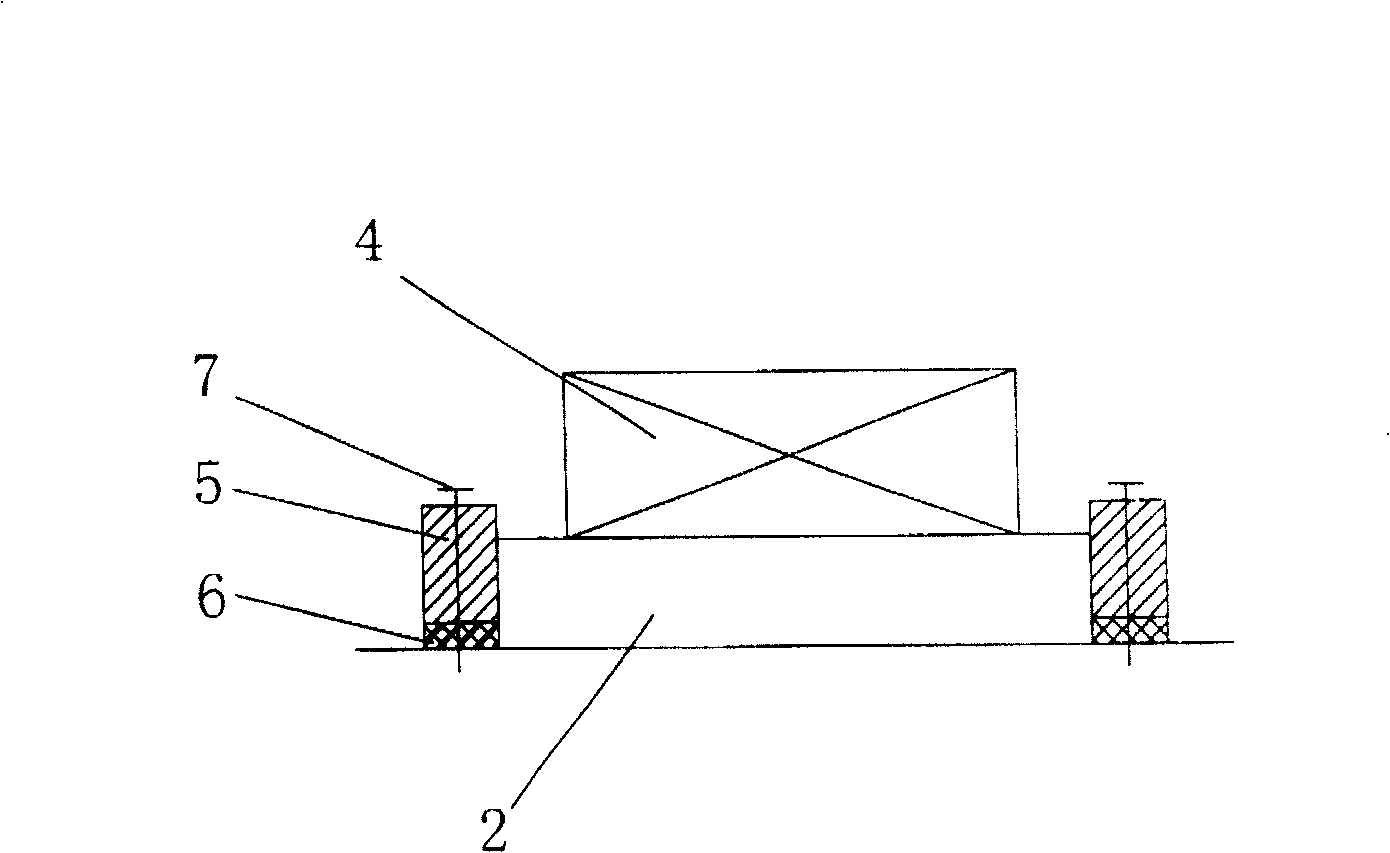

The low temperature construction method for grouting bridge support in the temperature lower than 10 deg.c, especially lower than 0 deg.c, includes heating the support bed stone in the pier top, pier anchor hole, lower bridge bearing steel plate, screw and sleeve, mortar stirrer, mortar pipe, etc partially or completely, taking heat insulating measures, and heating and maintaining the grouted mortar with heating bag and heat insulating jacket. The present invention has homogeneous heating of the mortar in and after grouting, and can ensure the global strength and antifreeze performance of anchoring mortar.

Description

technical field [0001] The invention relates to a low-temperature construction method of bridge support grouting technology, more specifically a construction method and technology for preventing mortar from hardening slowly due to low temperature after pouring, unable to harden or being damaged by freezing. technical background [0002] At present, my country has started large-scale construction of high-speed railways, and has adopted a large number of new processes and methods. In order to improve work efficiency and speed up the progress of the project, bridges prefabricated in factories are generally used. A bridge generally weighs 900 tons. The beam machine erects the bridge on the constructed pier, and connects the bridge and the pier through the bridge support. The bridge support and the bridge are connected by high-strength bolts. In order to adjust the height of the bridge, high-strength grouting mortar is cast on the support on site. The bridge support and concrete pi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E01D21/00

Inventor 佘海龙

Owner 北京建工华创工程技术有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com