Spray gun with improved needle type cut-off valve sealing device

A closed position, injection device technology, applied in the direction of injection device, injection device, liquid injection device, etc., can solve the problems of time-consuming and expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

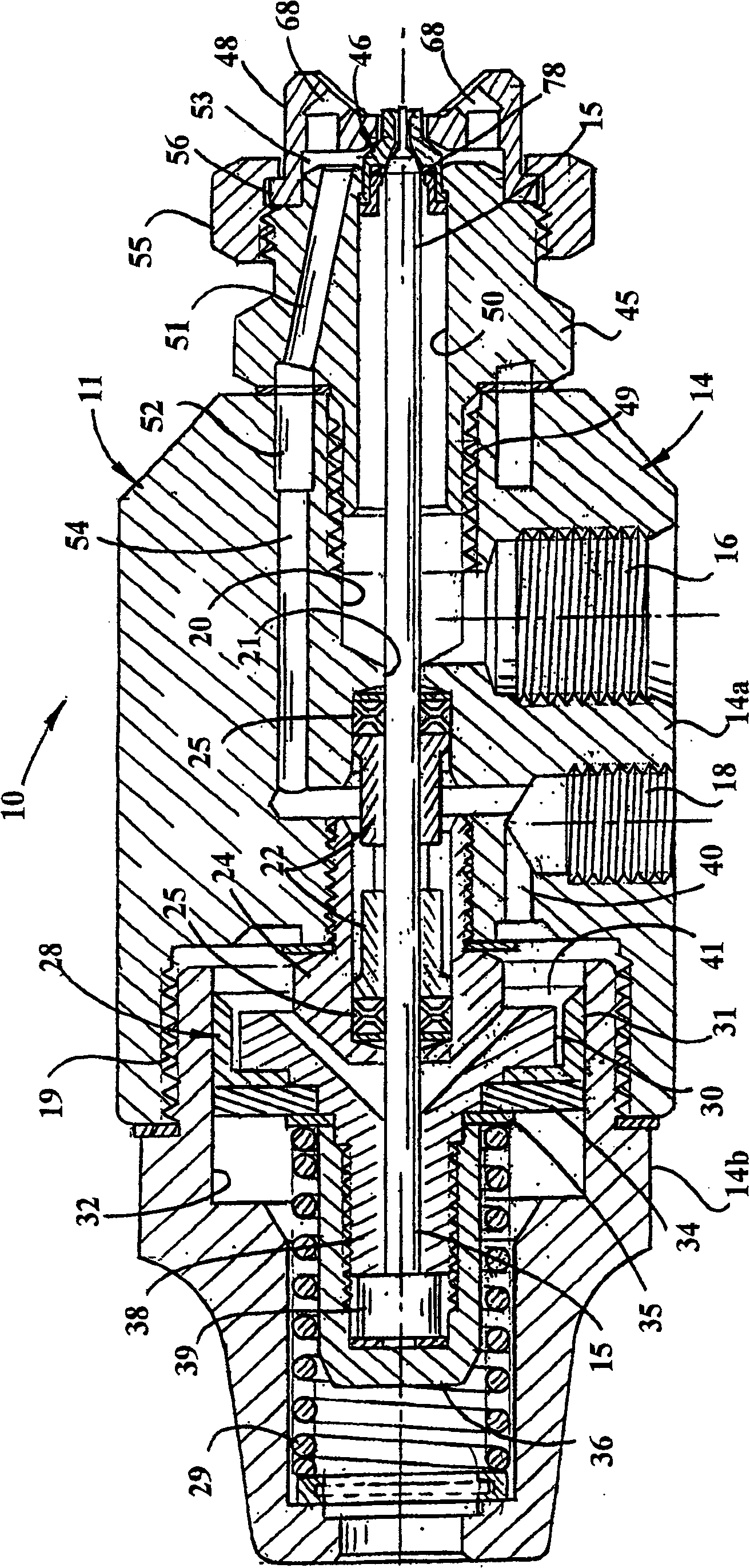

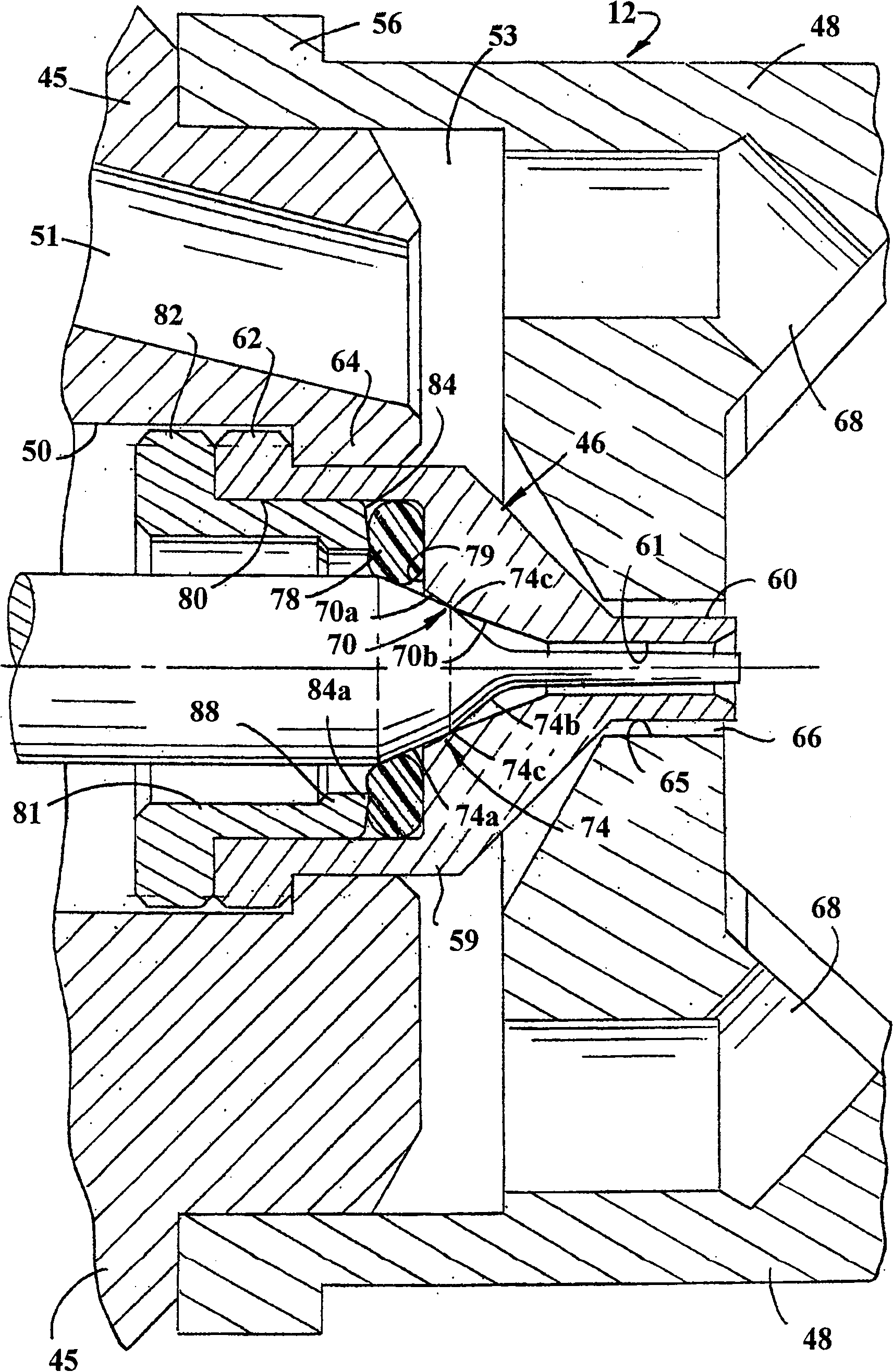

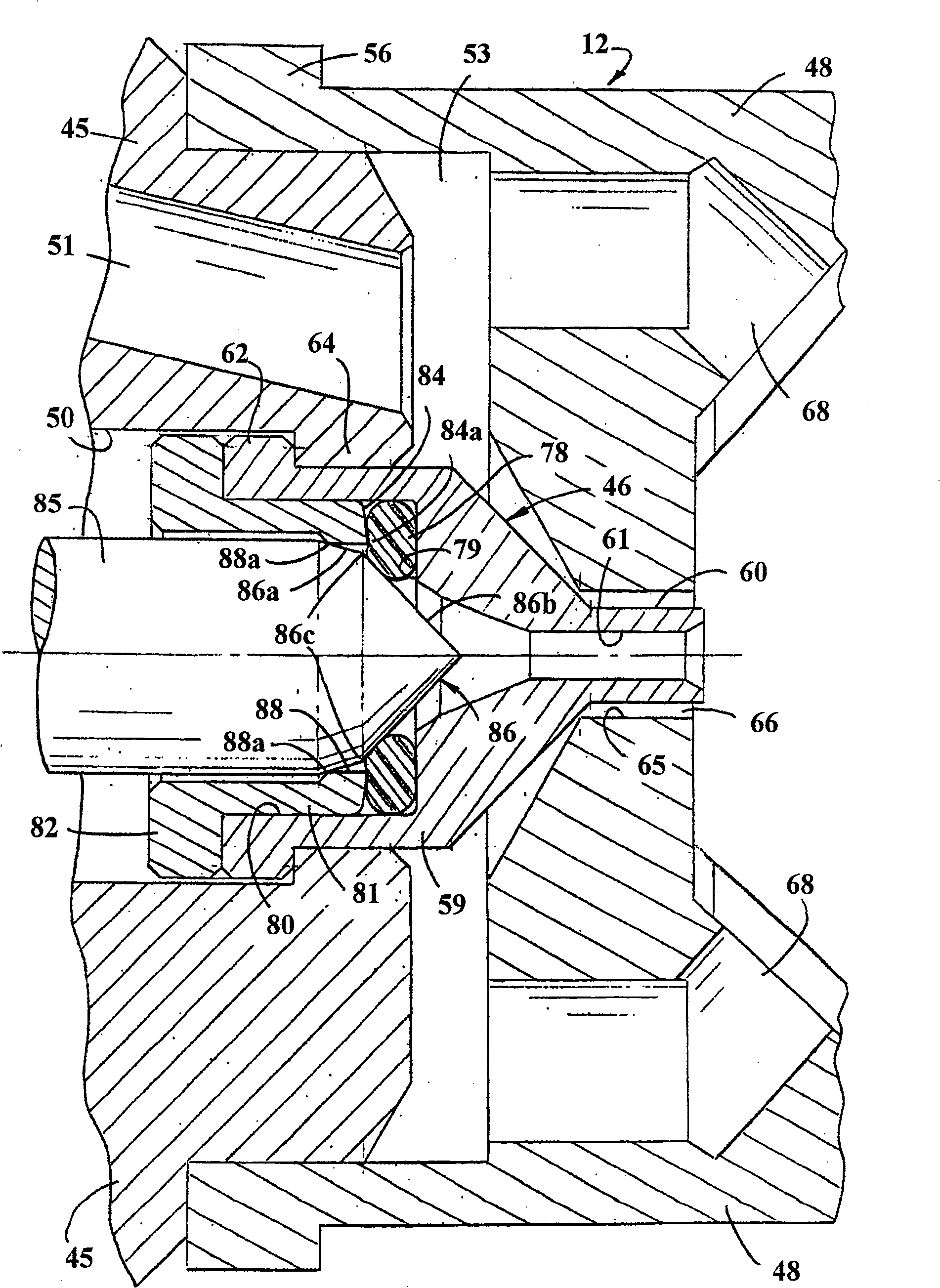

[0022] Referring now in more detail to the drawings, there is shown a spraying device 10 comprising a spray gun 11 having a nozzle assembly 12 in accordance with the present invention. The basic structure and manner of operation of the spray gun 11 is known in the art, for example as shown in the aforementioned US Patent 5,707,010, which is incorporated herein by reference. The overall structure and manner of operation of the spray gun 11 is to be understood as merely illustrative of one example of a spray device employing the nozzle assembly of the present invention.

[0023] The illustrated spray gun 11 comprises a main housing 14 axially supporting a shut-off valve needle 15 and having a fluid inlet 16 connected to a source of fluid to be sprayed and an auxiliary fluid inlet 18 connected, for example, to a source of compressed air, In order to assist in the atomization of the fluid to be sprayed, and to allow the controlled axial movement of the valve needle 15 between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com