Fibre-optical sensing device for monitoring metal rust

A technology of optical fiber sensing and optical fiber, which is applied in the direction of measuring device, phase influence characteristic measurement, material analysis through optical means, etc., to achieve the effect of simple structure, easy manufacture, and high initial corrosion sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

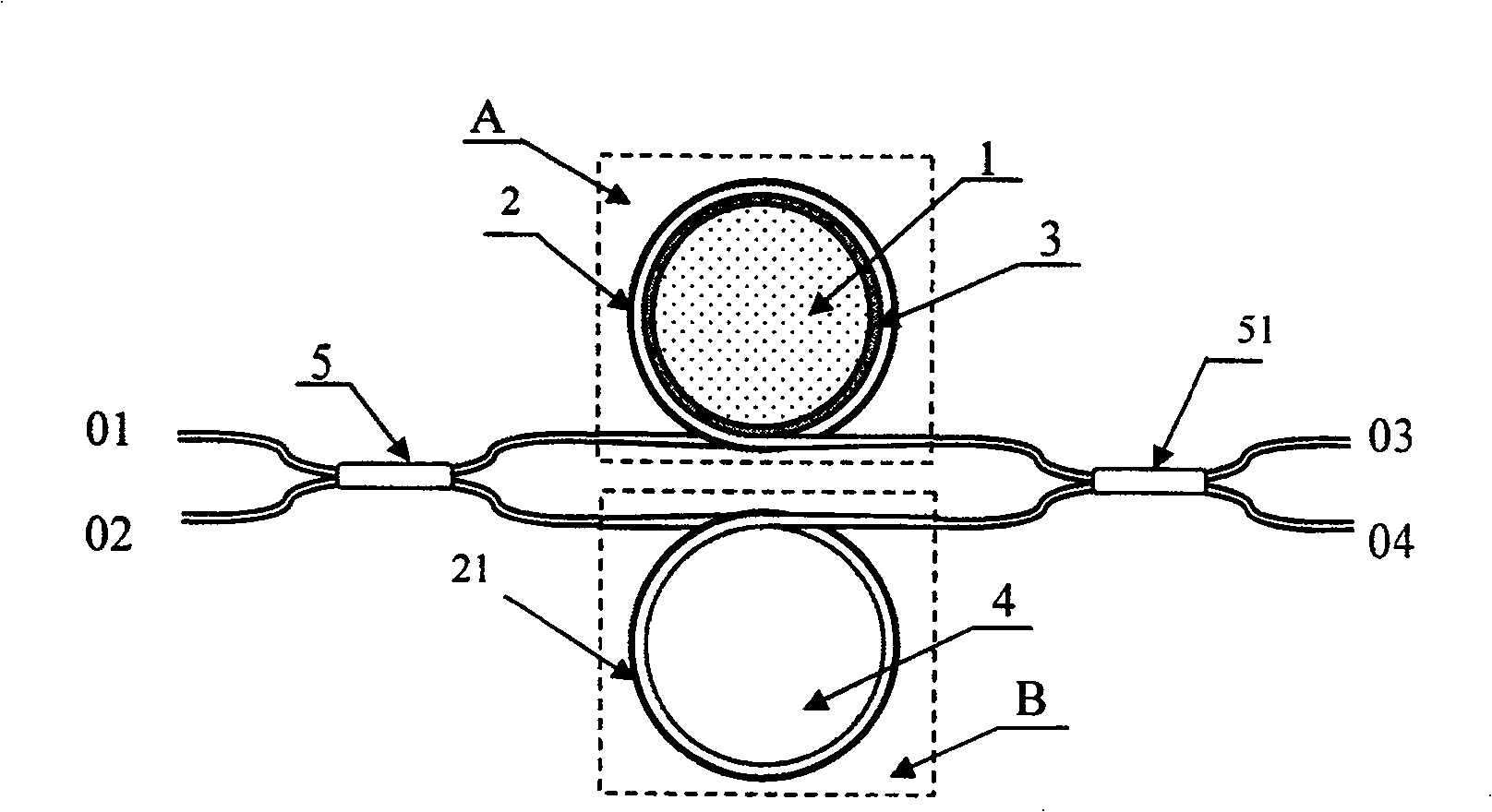

[0027] see first image 3 , image 3 Embodiment 1 of the present invention—a schematic diagram of a Mach-Zehnder interferometer, as can be seen from the figure, the optical fiber sensing device for monitoring metal corrosion of the present invention, its composition includes:

[0028] A detection head A is formed by winding N turns of the first optical fiber 2 on the cylindrical metal structure material 1 to be monitored;

[0029] A reference head B is formed by winding N turns of the second optical fiber 21 on a corrosion-resistant material 4 having the same configuration and radius as the metal structural material 1 to be monitored;

[0030] One end of the first optical fiber 2 of the probe head A and one end of the second optical fiber 21 of the reference head B are coupled through the first optical fiber coupler 5 with a beam splitting ratio of 1:1 to form the first port 01 and the second port 02, the other ends of the first optical fiber 2 and the second optical fiber 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com