Lithium ion battery capable of low-temperature working

A lithium-ion battery and working technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of one-sided failure to comprehensively consider the low temperature performance and high temperature characteristics of the battery, so as to ensure the viscosity of the electrolyte and the ionic conductivity. The effect of ensuring low temperature discharge performance, good electrolyte viscosity and ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

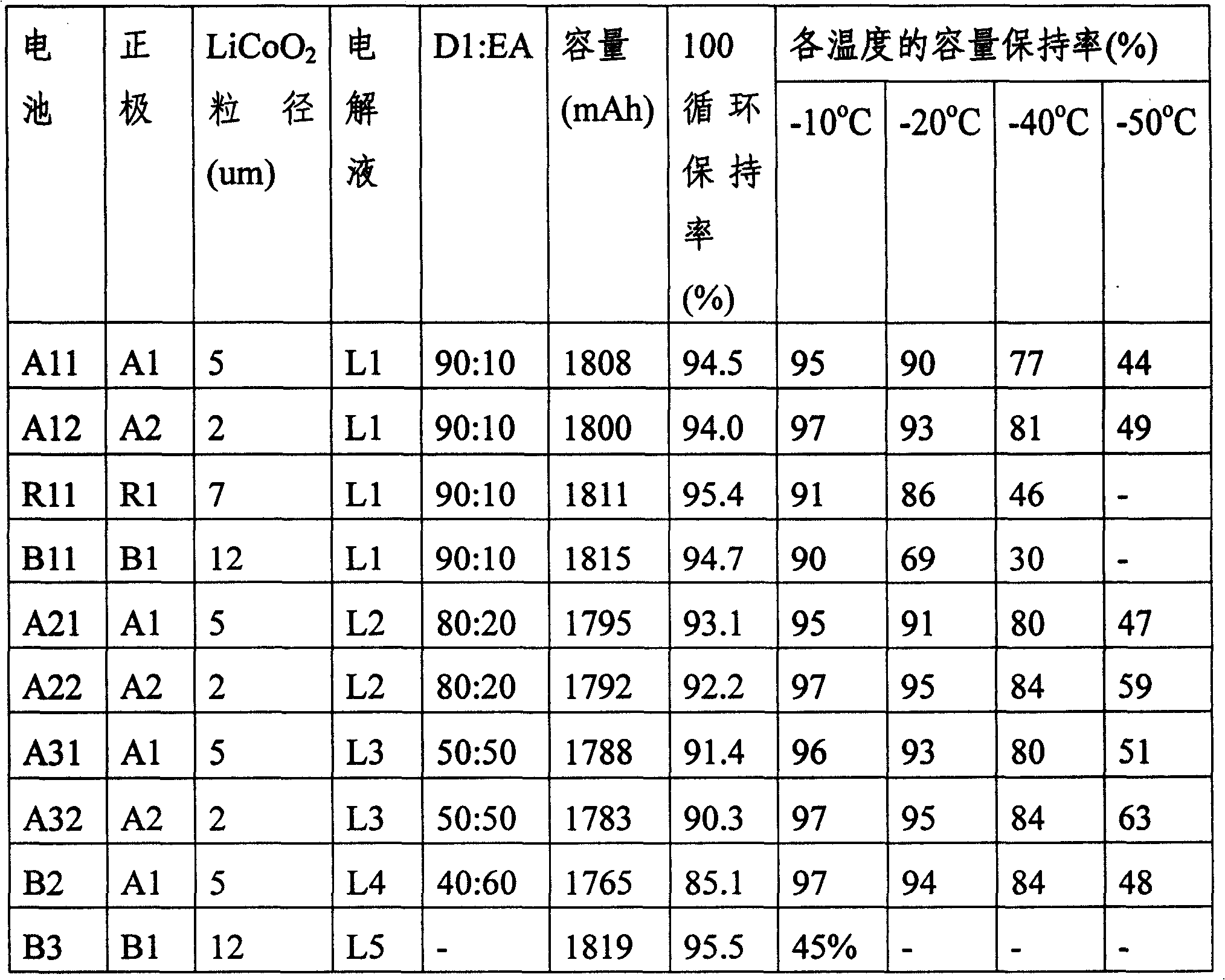

[0016] Embodiment 1: According to the following procedure, select LiCoO 2 10 kinds of batteries were prepared with different particle sizes and different ratios of D1:EA for data test:

[0017] Preparation of positive plates containing lithium cobalt oxide with various particle sizes: LiCoO with an average D50 particle size of 12 microns 2 The powder is ball milled and reclassified to make four kinds of D50: 12 microns, 7 microns, 5 microns and 2 microns. Then, weigh the above-mentioned positive electrode active materials with different particle sizes, and make LiCoO with a solid content of 93wt% respectively. 2 , the NMP solution of 4.5wt% PVdF binding agent, the conductive material of 2.5wt% acetylene black: VGCF=2: 1, the three are mixed to form positive electrode mixture, add NMP in the mixture and prepare paste with stirrer, then put Coating weight is 43mg / cm 2 The paste was evenly applied to both sides of aluminum foil with a thickness of 20 μm, and then dried and rol...

Embodiment 2

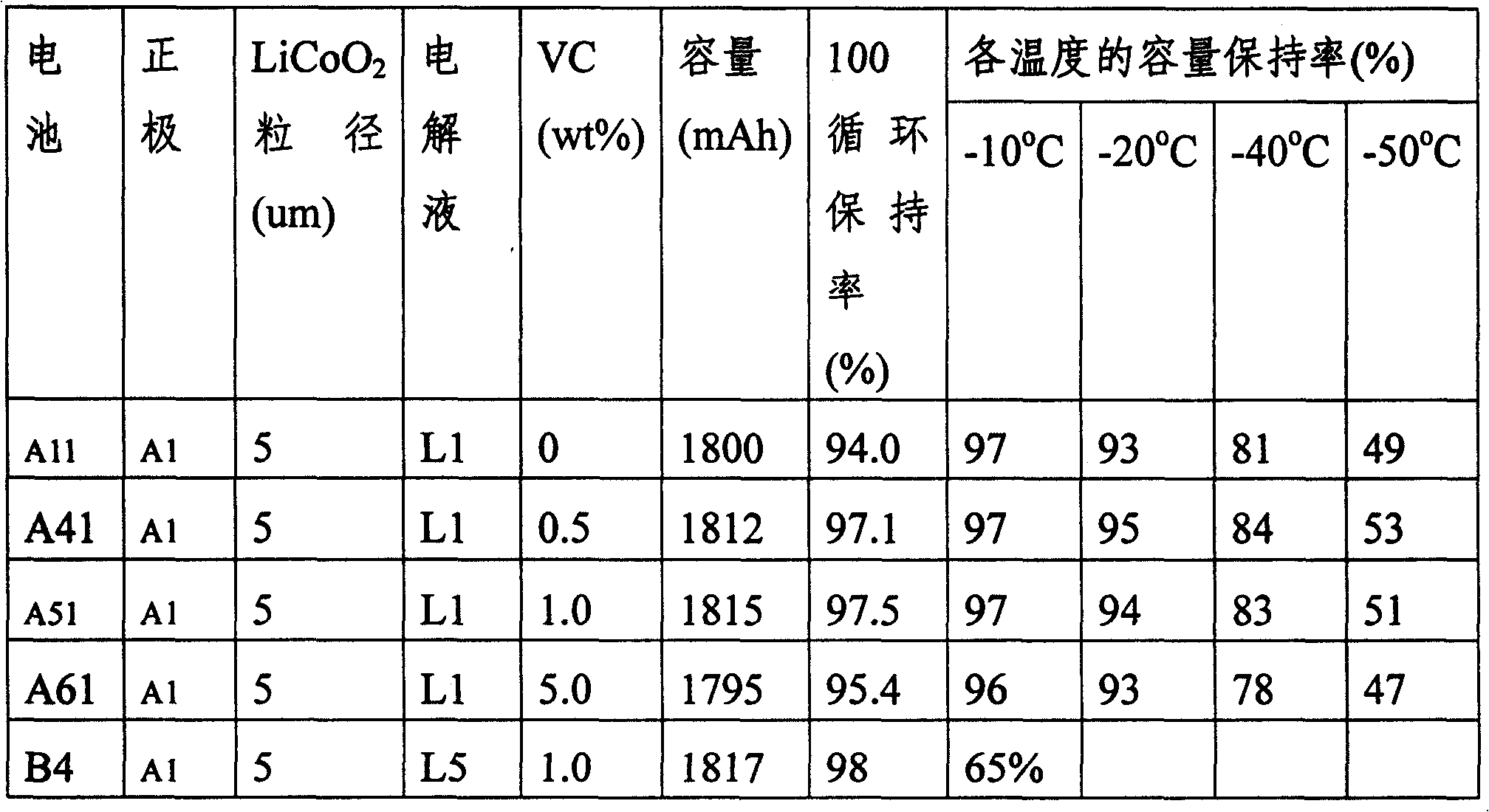

[0027]Follow the procedure below, select LiCoO 2 The particle size is 5 microns, and different amounts of VC are added to the following electrolytes to prepare A41, A51, A61, and B4. The test data of the 4 batteries are compared with the battery A11 in Example 1:

[0028] Preparation of the positive plate of lithium cobalt oxide: LiCoO with an average D50 particle size of 12 microns 2 The powder is ball milled and then made into a particle size of 5 microns. Then take the positive electrode active material to make LiCoO with a content of 93wt% in the solid component 2 , the NMP solution of 4.5wt% PVdF binding agent, the conductive material of 2.5wt% acetylene black: VGCF=2: 1, the three are mixed to form positive electrode mixture, add NMP in the mixture and prepare paste with stirrer, then put Coating weight is 43mg / cm 2 The paste was evenly applied to both sides of aluminum foil with a thickness of 20 μm, and then dried and rolled to obtain a positive plate. D50 is the p...

Embodiment 3

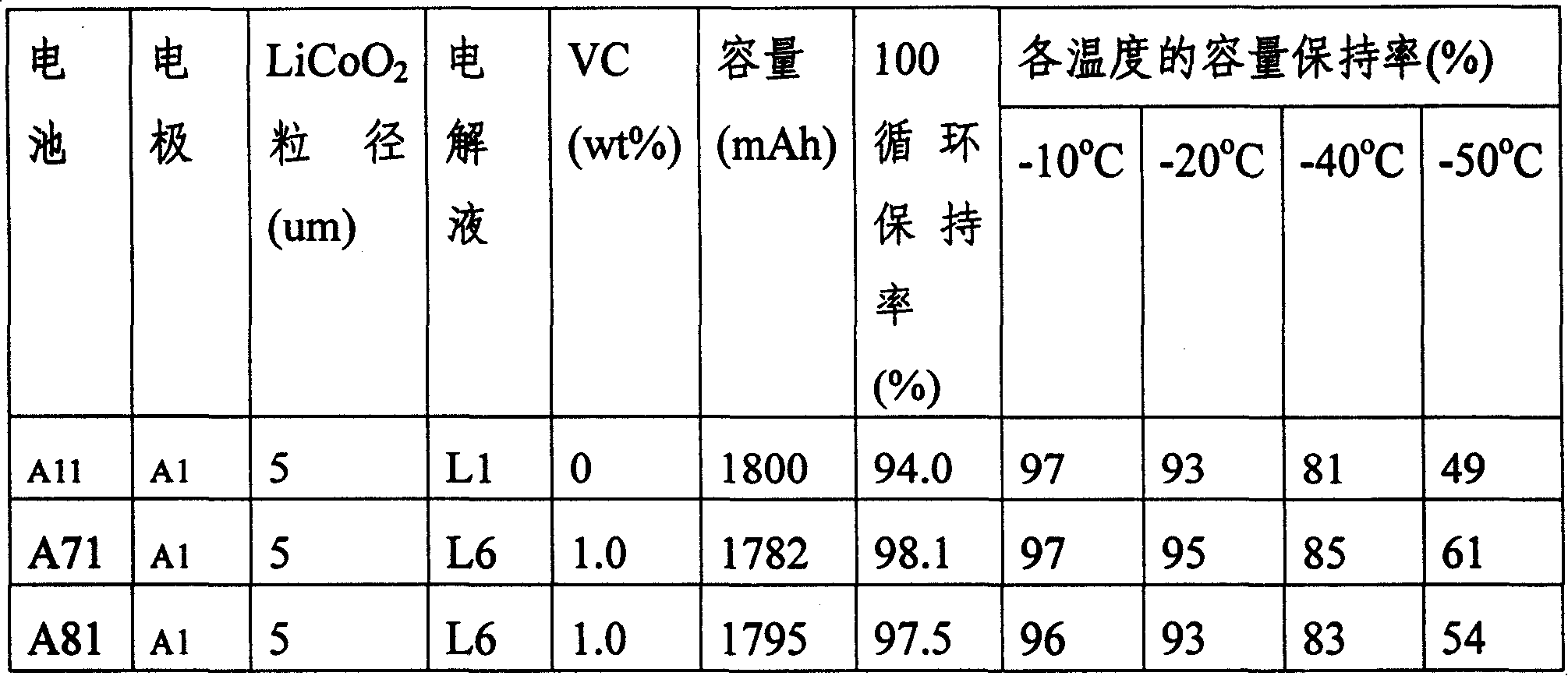

[0038] Follow the procedure below, select LiCoO 2 Particle diameter 5 microns, do not add VC and add VC in the following electrolytic solution, prepare 2 batteries A71, A81, carry out test data comparison with battery A11 in the embodiment 1:

[0039] Preparation of the positive plate of lithium cobalt oxide: LiCoO with an average D50 particle size of 12 microns 2 The powder is ball milled and then made into a particle size of 5 microns. Then take the positive electrode active material to make LiCoO with a content of 93wt% in the solid component 2 , the NMP solution of 4.5wt% PVdF binding agent, the conductive material of 2.5wt% acetylene black: VGCF=2: 1, the three are mixed to form positive electrode mixture, add NMP in the mixture and prepare paste with stirrer, then put Coating weight is 43mg / cm 2 The paste was evenly applied to both sides of aluminum foil with a thickness of 20 μm, and then dried and rolled to obtain a positive plate. D50 is the positive plate A1 made...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com