Light negative board mould set

A technology for backlight panels and modules, applied in optics, nonlinear optics, instruments, etc., can solve problems such as not being easy, users being discouraged, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The backlight panel module of the present invention, its use status diagram is as follows figure 1 What is displayed is located on the back side of the LCD panel to provide a backlight. figure 1 Among them, the backlight module of the present invention is arranged behind the polarizing plate 102 , a liquid crystal layer 104 and a color filter 103 are arranged between the polarizing plate 102 and the polarizing plate 101 , and a casing 105 is fixed around the polarizing plate 102 .

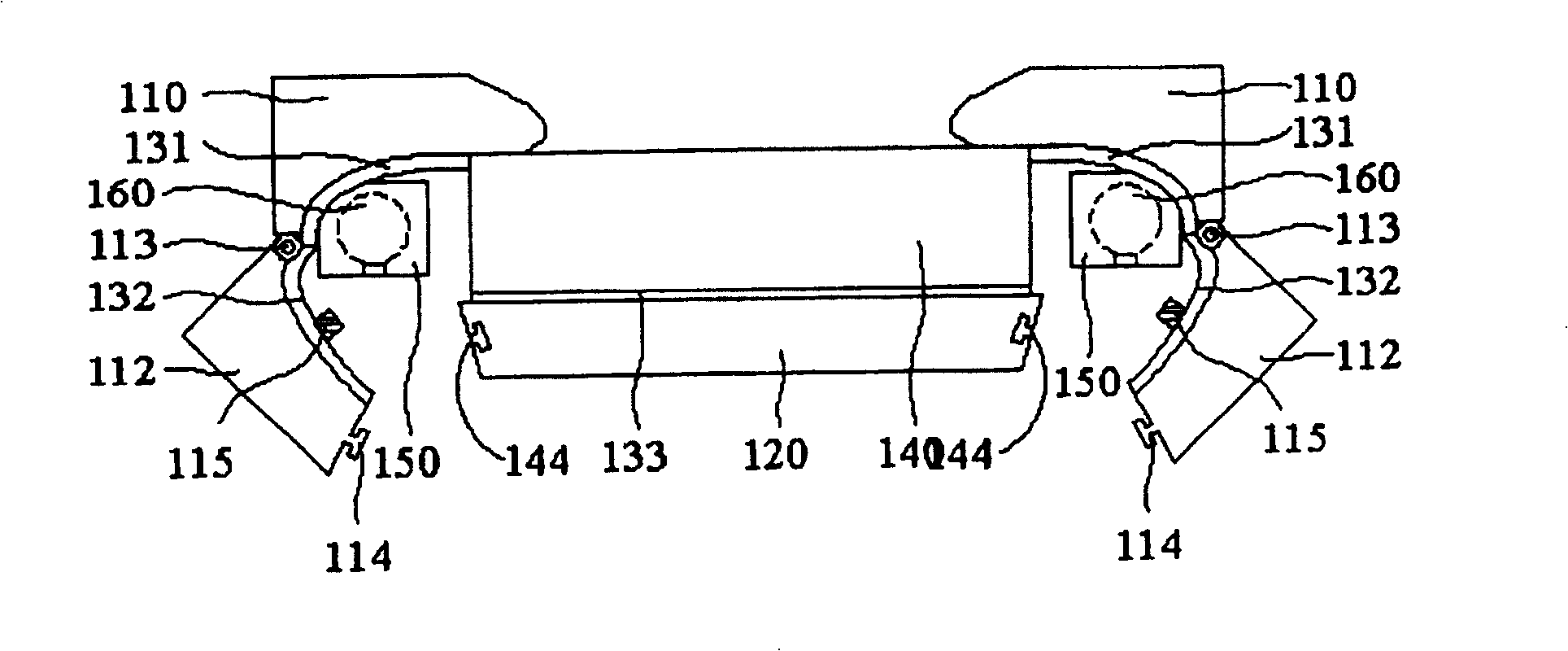

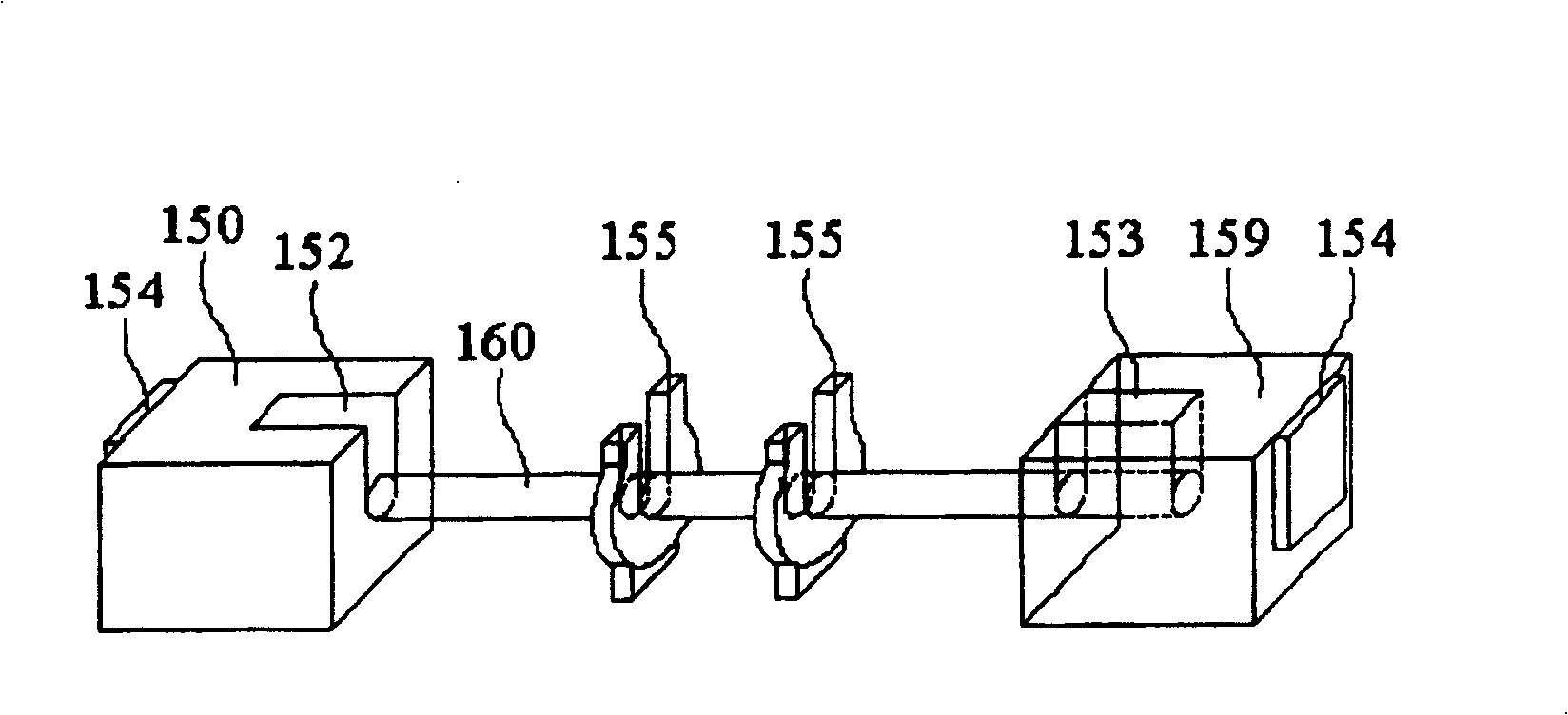

[0018] The first embodiment of the present invention, such as figure 2 What is shown includes a first housing 110 , a bottom cover 112 , a light tube 160 , a light guide plate 140 and a second housing 120 . The bottom cover 112 includes a rotating portion 113 and a fastener 114 , and the bottom cover 112 is connected to the first housing 110 through the rotating portion 113 . The lamp tube 160 is disposed in a space formed by the first casing 110 and the bottom cover 112 . The light guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com