A veneered raised panel element and method of manufacturing thereof

A veneer and component technology, applied in the field of veneer convex plate components and their manufacturing, can solve problems such as instability, warpage, lack of aesthetics, etc., and achieve the effects of strength improvement, warpage reduction, and appearance coordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The making and using of the presently preferred embodiments are discussed in detail below. It should be appreciated, however, that the present invention provides many applicable inventive concepts that can be embodied in a variety of forms as described. The specific embodiments discussed are merely illustrative of the making and using of the invention, and do not limit the scope of the invention.

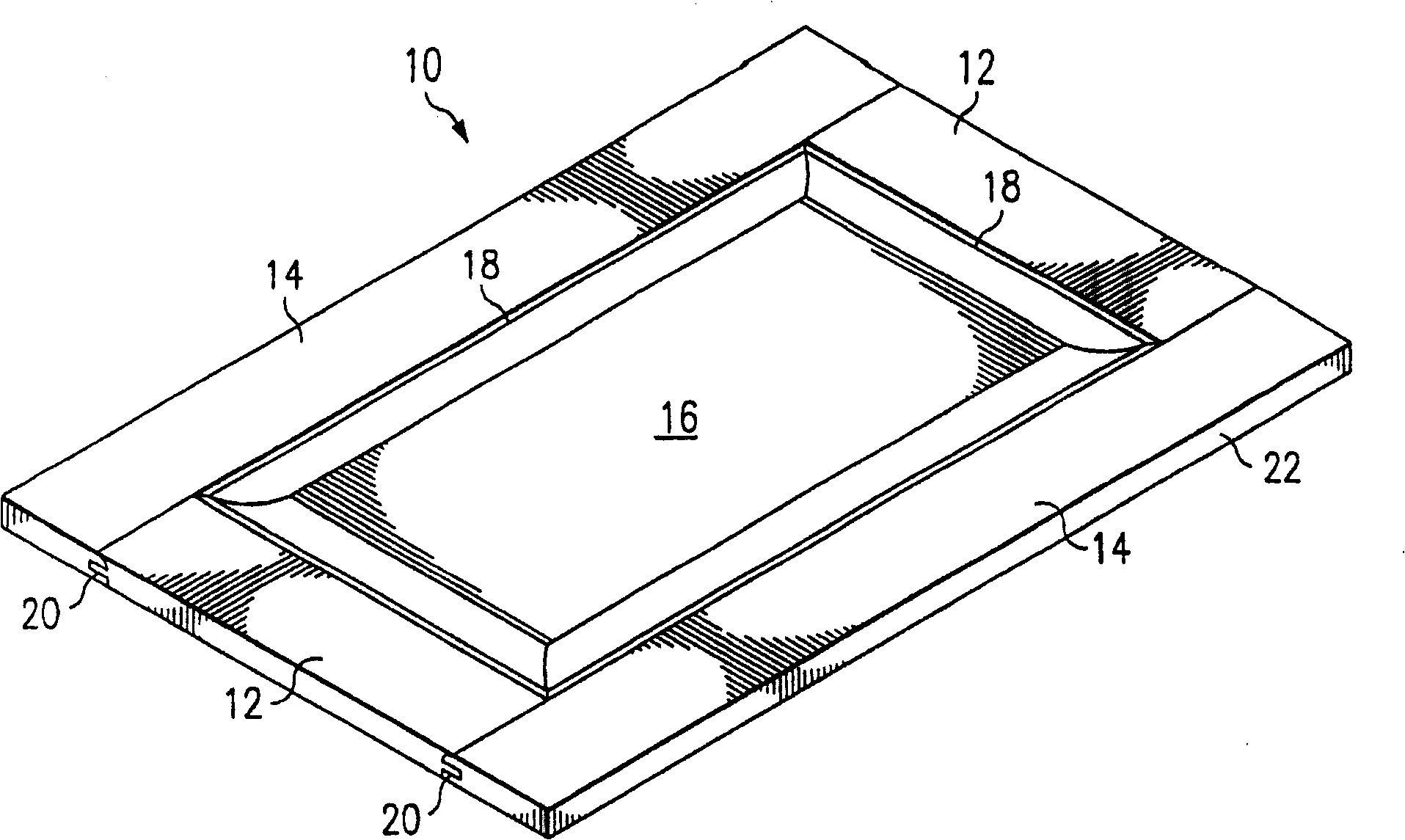

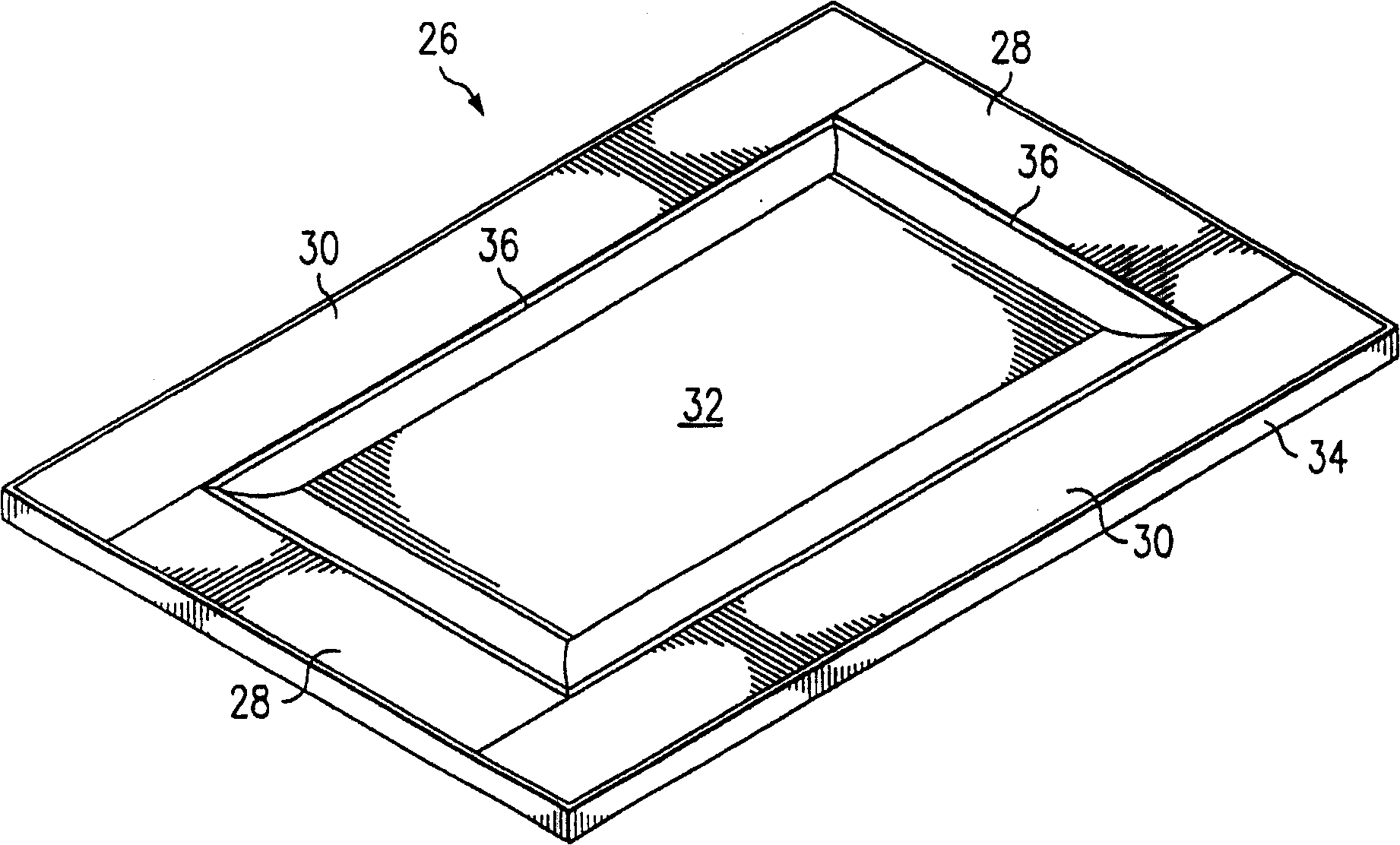

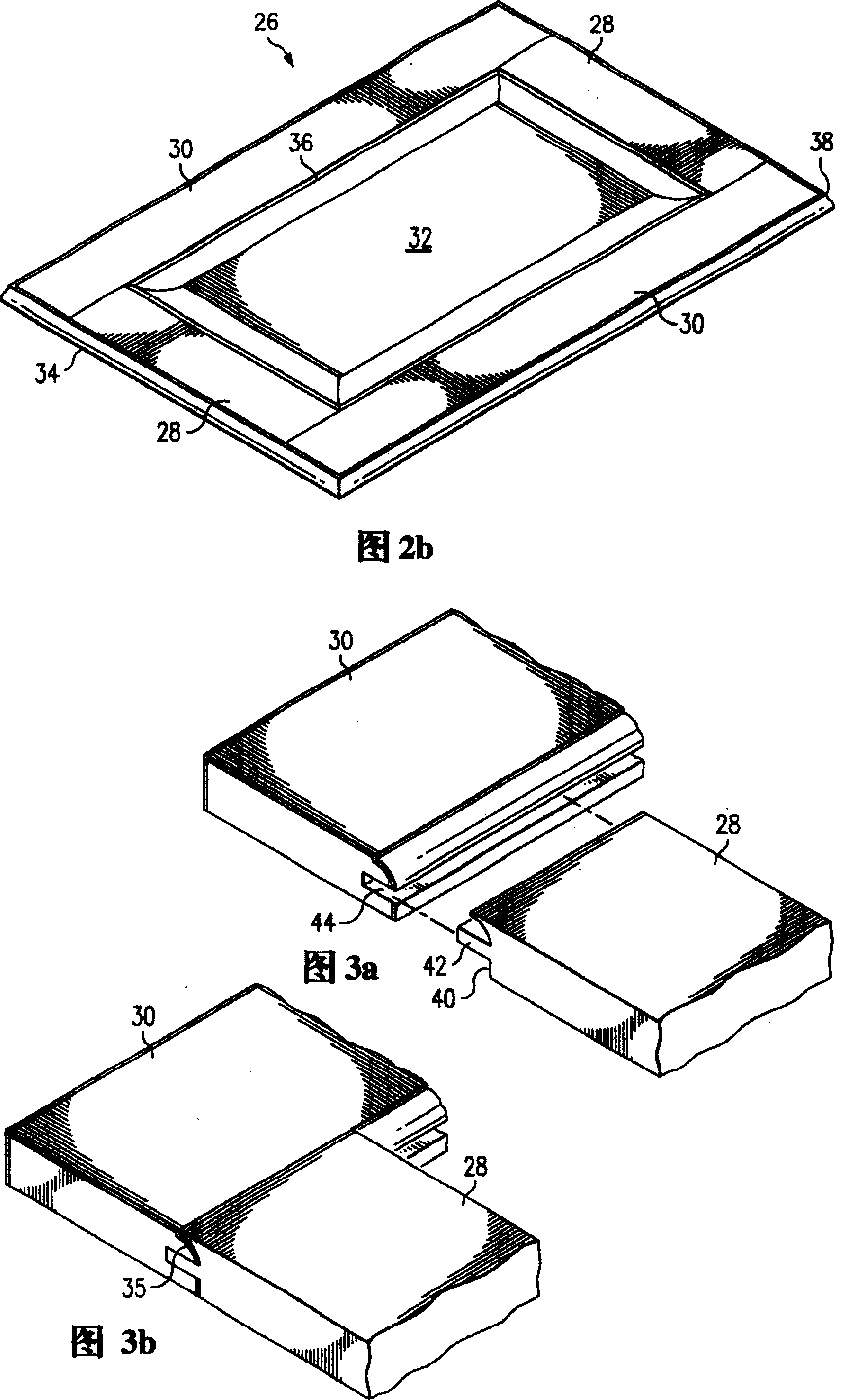

[0029] refer to Figure 2a and 2b, an isometric view of a preferred embodiment of a raised panel door 26 is shown. The door 26 includes horizontally oriented elements or rails 28 , vertically oriented elements or stiles 30 , a central panel 32 and side bars 34 . Overlay veneer veneers over a fabrication material such as pressed wood, medium density fiberboard (MDF), particle board, chipboard or other engineered core material to form rails 28, stiles 30 and center panels 32 . Both rail 28 and stiles 30 include inner edges 36 which may be of simple construction or profiled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com