Liquid cooling foods freezer

A freezing device and food technology, which is applied to household refrigeration devices, cooling fluid circulation devices, food preservation and other directions, can solve the problems of complicated assembly, increased cost, time-consuming and other problems, and achieves simple assembly, efficient cooling, and easy expansion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

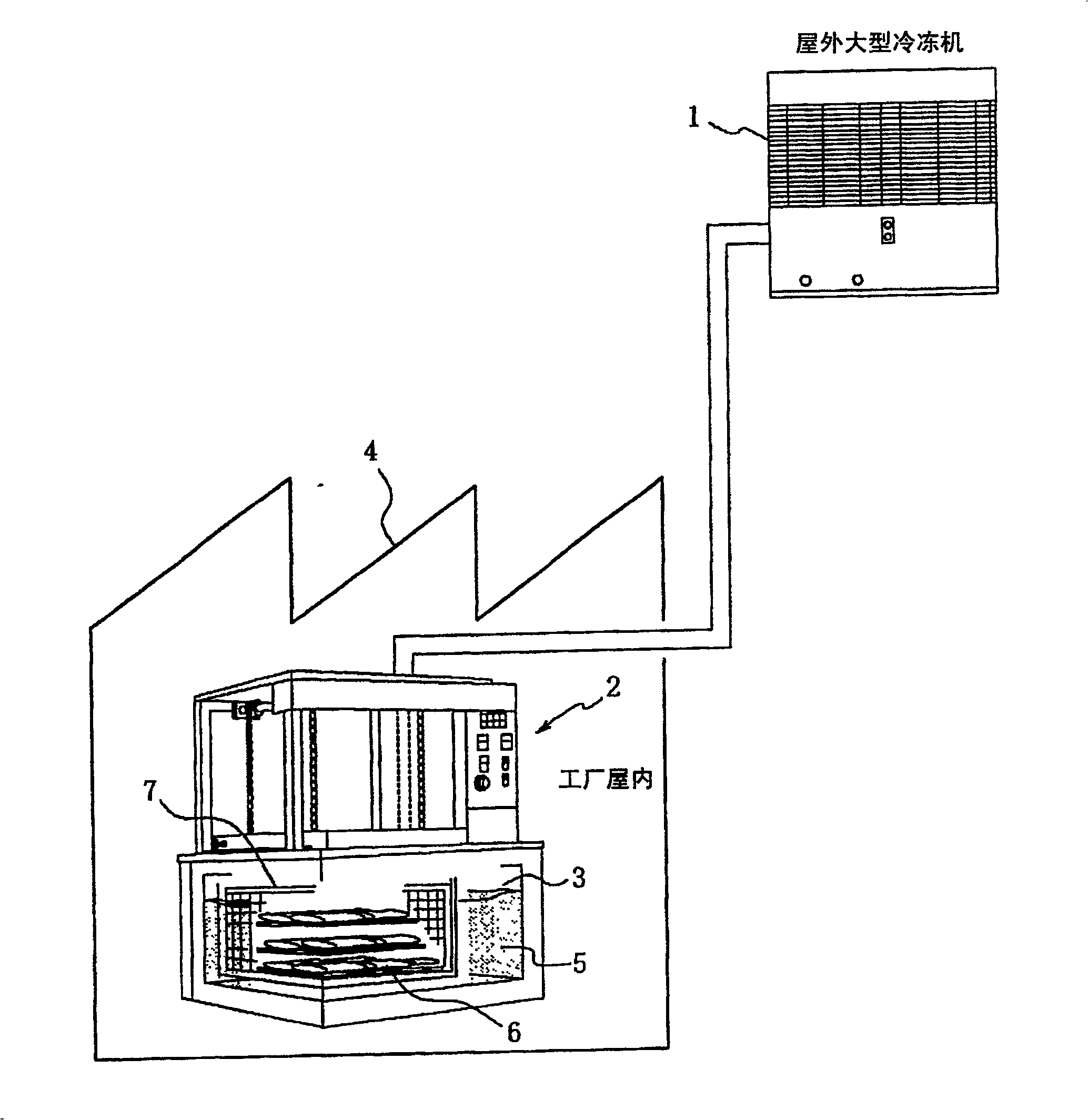

[0030] figure 1 It shows a refrigeration plant 4 that supplies refrigerant to a heat exchange piping mechanism that is piped in an antifreeze tank 3 that is an antifreeze tank mechanism of an indoor liquid-cooled food freezing device 2 through a large outdoor cooling pressure-feeding mechanism (that is, a refrigerator) 1 the embodiment. An appropriate amount of antifreeze (antifreeze bath) 5 is accommodated in the antifreeze tank 3, and the packaged food 6 is soaked in the antifreeze (bath) 5 by a transport mechanism 7 carrying packaged food 6 . In the illustrated embodiment, the transport mechanism 7 is a shelf that can be lifted and lowered freely, and a conveyor belt can also be used. The illustrated embodiment is a freezing factory, which can also be installed in common restaurants. In addition, the food carried on the conveyance mechanism 7 may also be carried naked without packaging.

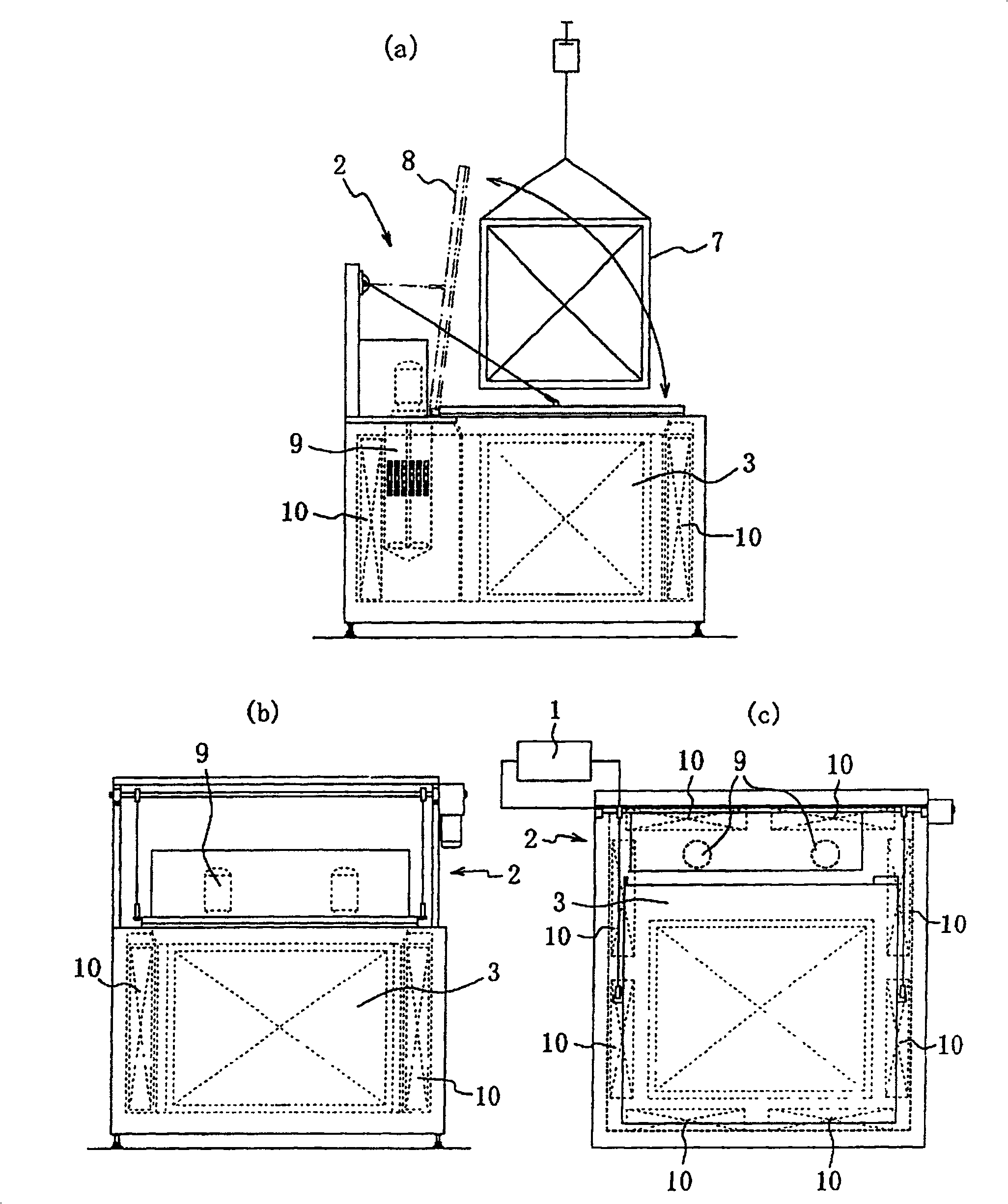

[0031] figure 2 The first embodiment of the liquid-cooled food freezing device 2 ...

Embodiment 2

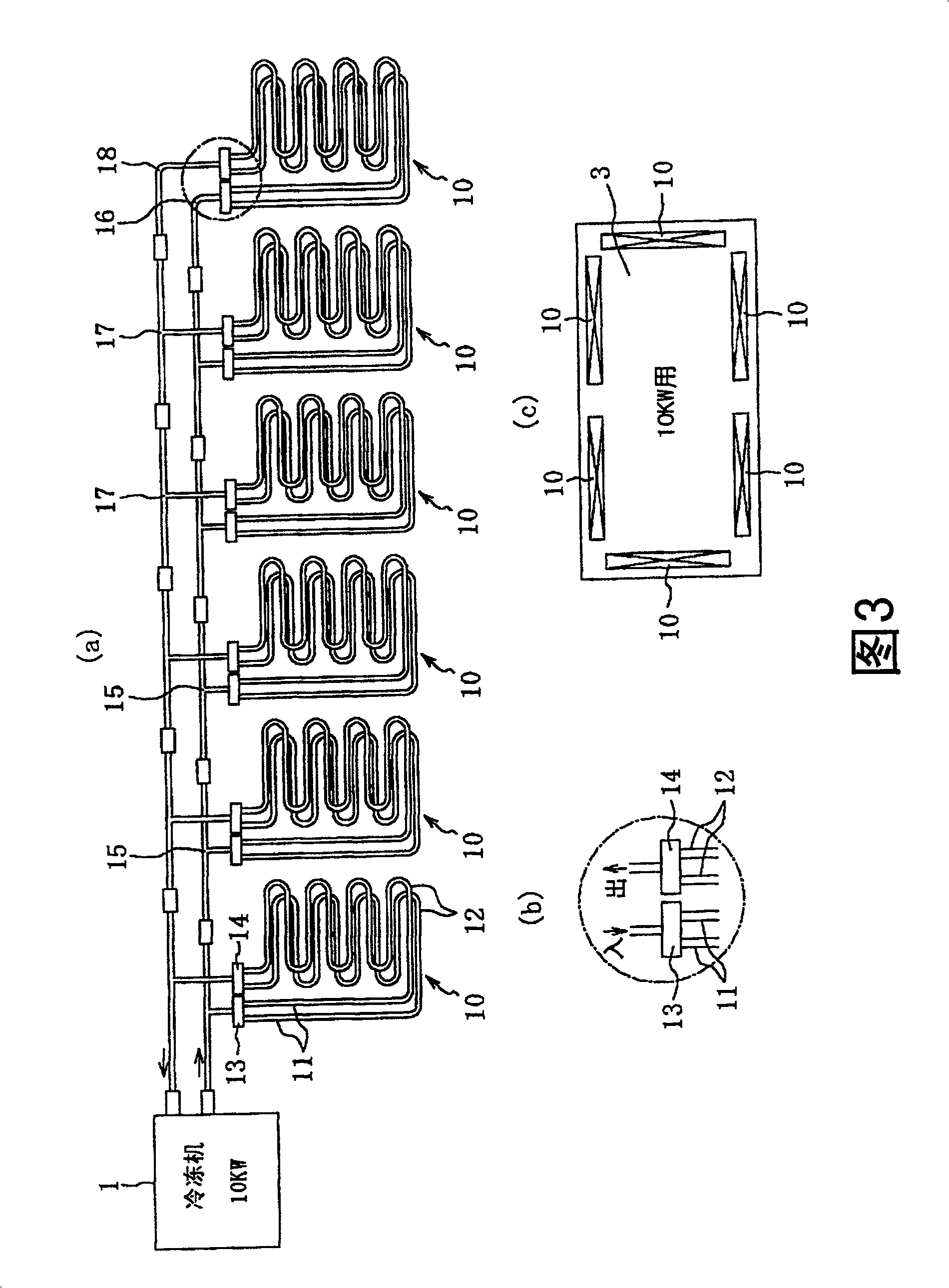

[0033] FIG. 3 shows a second embodiment in which six piping units 10 are arranged around the four side walls of the rectangular antifreeze tank 3 . According to the present invention, the piping unit 10 is composed of two vertical pipe parts 11, two serpentine pipe parts 12 that bend horizontally from these vertical pipe parts 11 and meander along the wall surface, an inlet side manifold port 13, and an outlet side manifold. Port 14 is modular as a unit.

Embodiment 3

[0035] FIG. 4 shows a third embodiment in which eight piping units 10 are arranged around the four side walls of the rectangular antifreeze tank 3 . According to the present invention, the piping unit 10 is composed of four vertical pipe parts 11, four serpentine pipe parts 12 that bend horizontally from these vertical pipe parts 11 and meander along the wall surface, an inlet side manifold port 13, and an outlet side manifold. Port 14 is modular as a unit.

[0036] include figure 2 In the embodiment of ~4, the heat exchange piping mechanism of the liquid-cooled food freezing device of the present invention is constituted as follows: a plurality of piping units 10 are arranged in order along the entire circumference of the side wall of the antifreeze tank 3, and the inlet side manifold Port 13 is connected in parallel with the outlet side manifold mechanism, and the outlet side manifold port 14 is connected in parallel with the return side manifold mechanism. continue. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com