Coupling for a steel spiral flexible hose

A technology of spiral hose and connector, applied in the direction of hose connection device, pipe/pipe joint/pipe fitting, application, etc., to achieve the effect of reliable fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

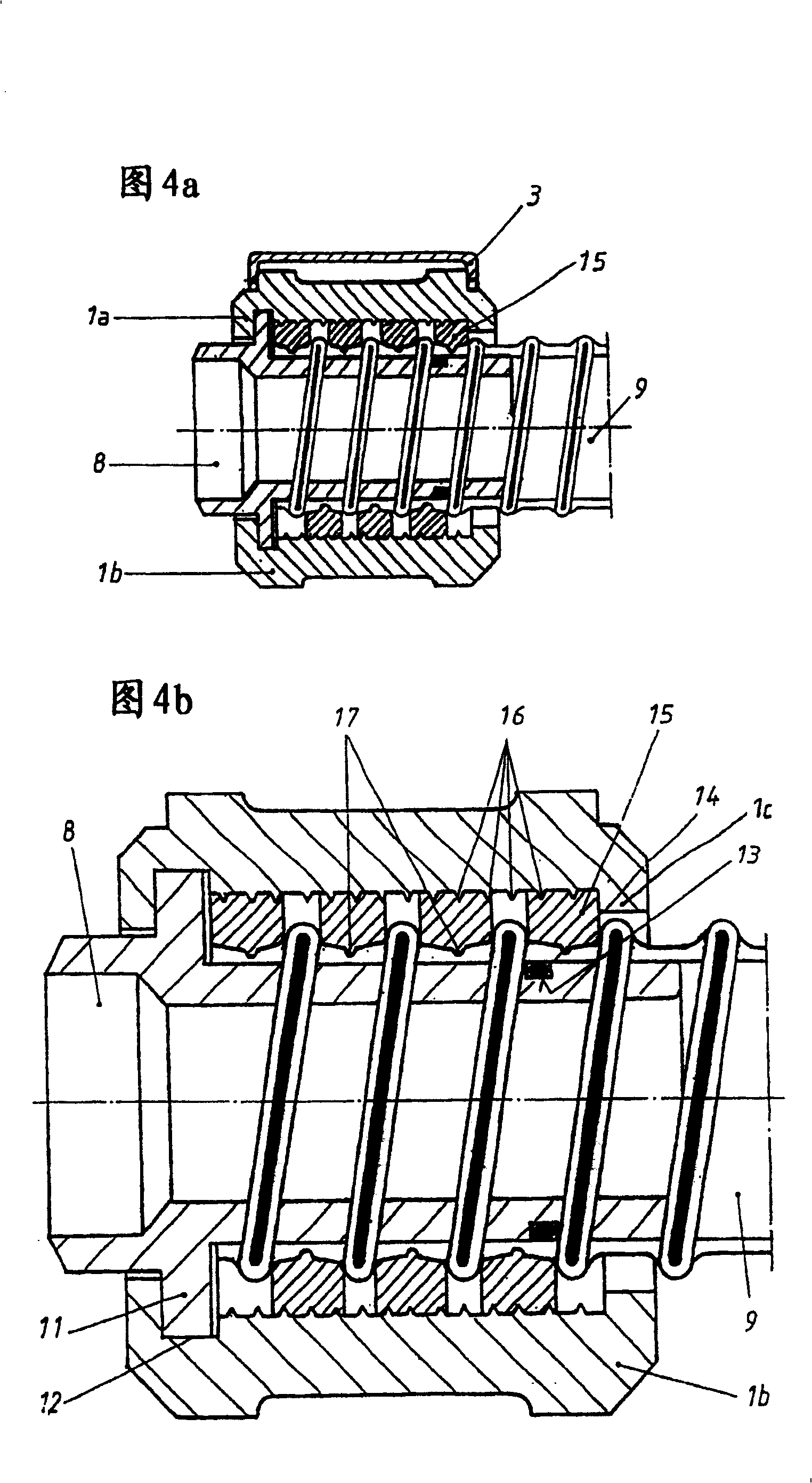

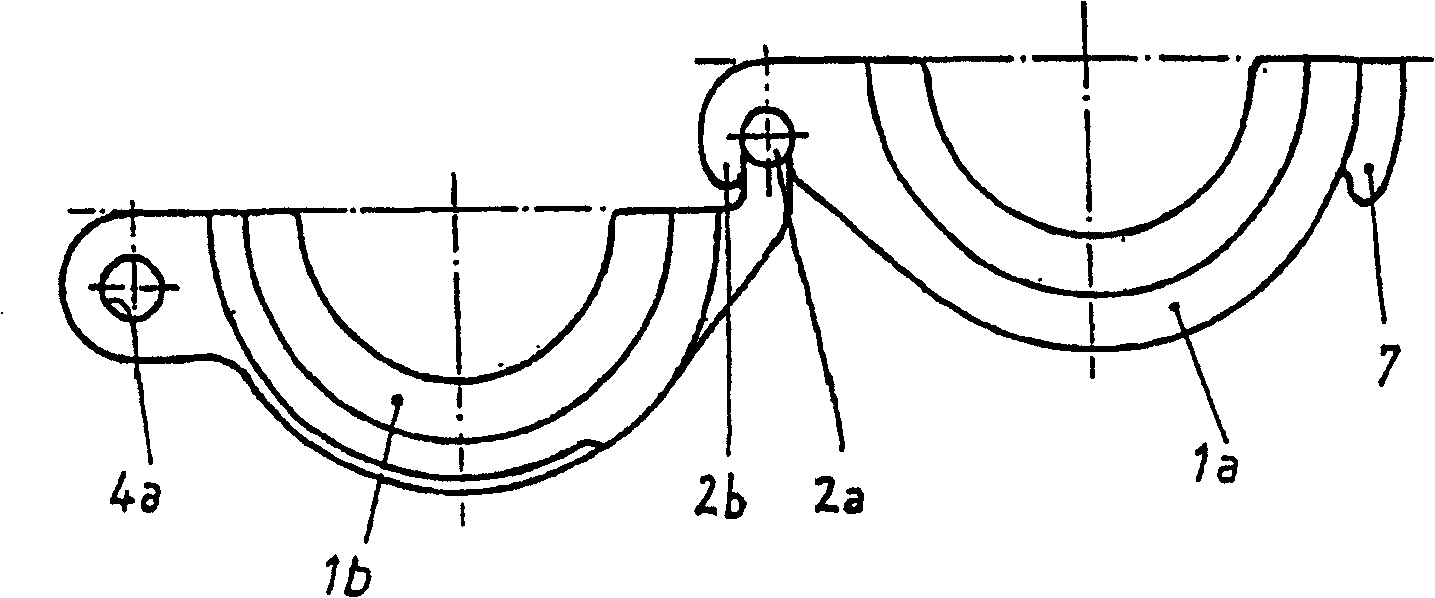

[0020] Figures 1 to 3 show three different views of the connector of the invention. The core part of the connector is a clamping clip 1 which, in the illustrated and therefore preferred embodiment, comprises two separate partial shells 1a and 1b. As can be seen in particular from FIGS. 1 and 3, the two partial shells are hingedly connected to each other via a hinge 2, wherein one end of the partial shell 1a has two shaped pins 2a which are formed by a correspondingly formed lug of the partial shell 1b. 2b Hooked surround.

[0021] In a preferred embodiment, the shown connector also has an easy-to-use quick clamping device, wherein the clamping clip 1 has a clamping lever 3 at the free peripheral end of the partial shell 1a, which can be moved by means of a bolt 4. It is rotatably hinged to the partial shell 1a, as can be seen from FIGS. 1 and 2 . The clamping lever 3 also has a pin 5 for fixing one end of a locking spring 6 . In this case, the free end of the locking spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com