Tilted variable axial piston device

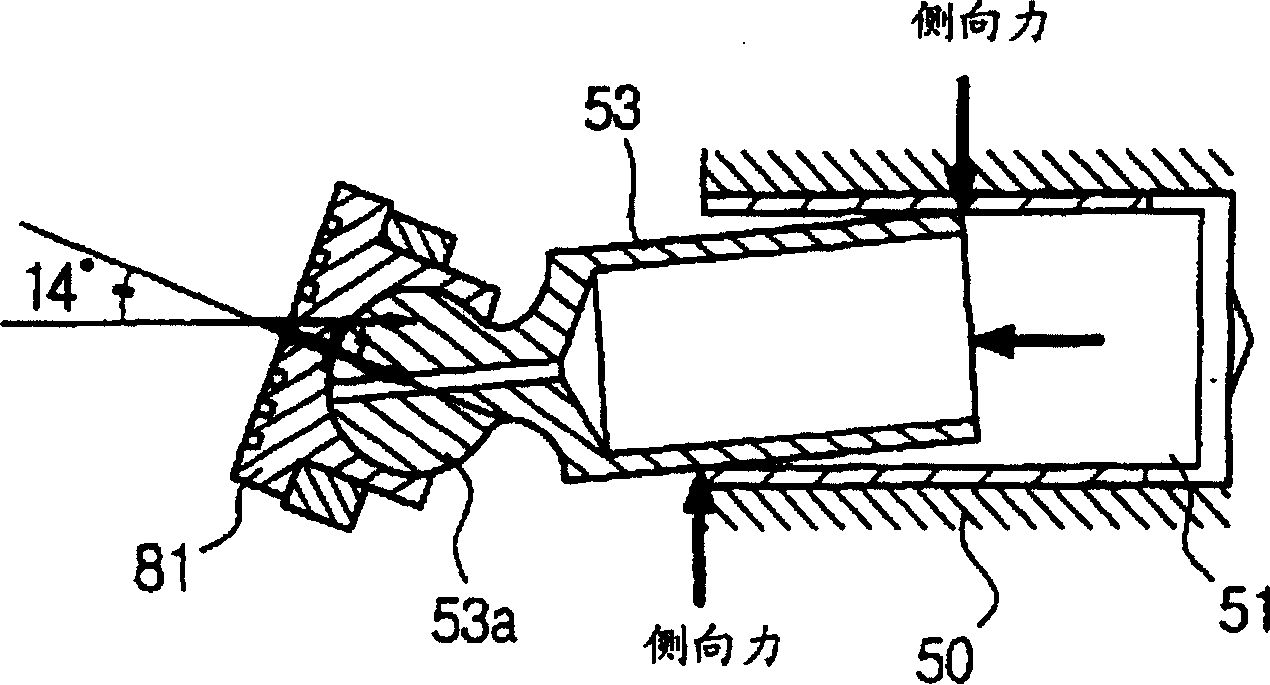

A technology of axial piston and swash plate type, which is applied in the direction of reciprocating piston engines, transmission devices, fluid transmission devices, etc., can solve the problem of shortening the life of the oil cylinder 51 and piston 53, affecting the reciprocating motion of the piston 53, and design restrictions on the angle of the swash plate 70, etc. problem, achieve the effect of increasing mechanical efficiency, avoiding friction and shortening length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The best implementation form of the variable swash plate type axial piston device of the present invention will be described in detail below with reference to the accompanying drawings.

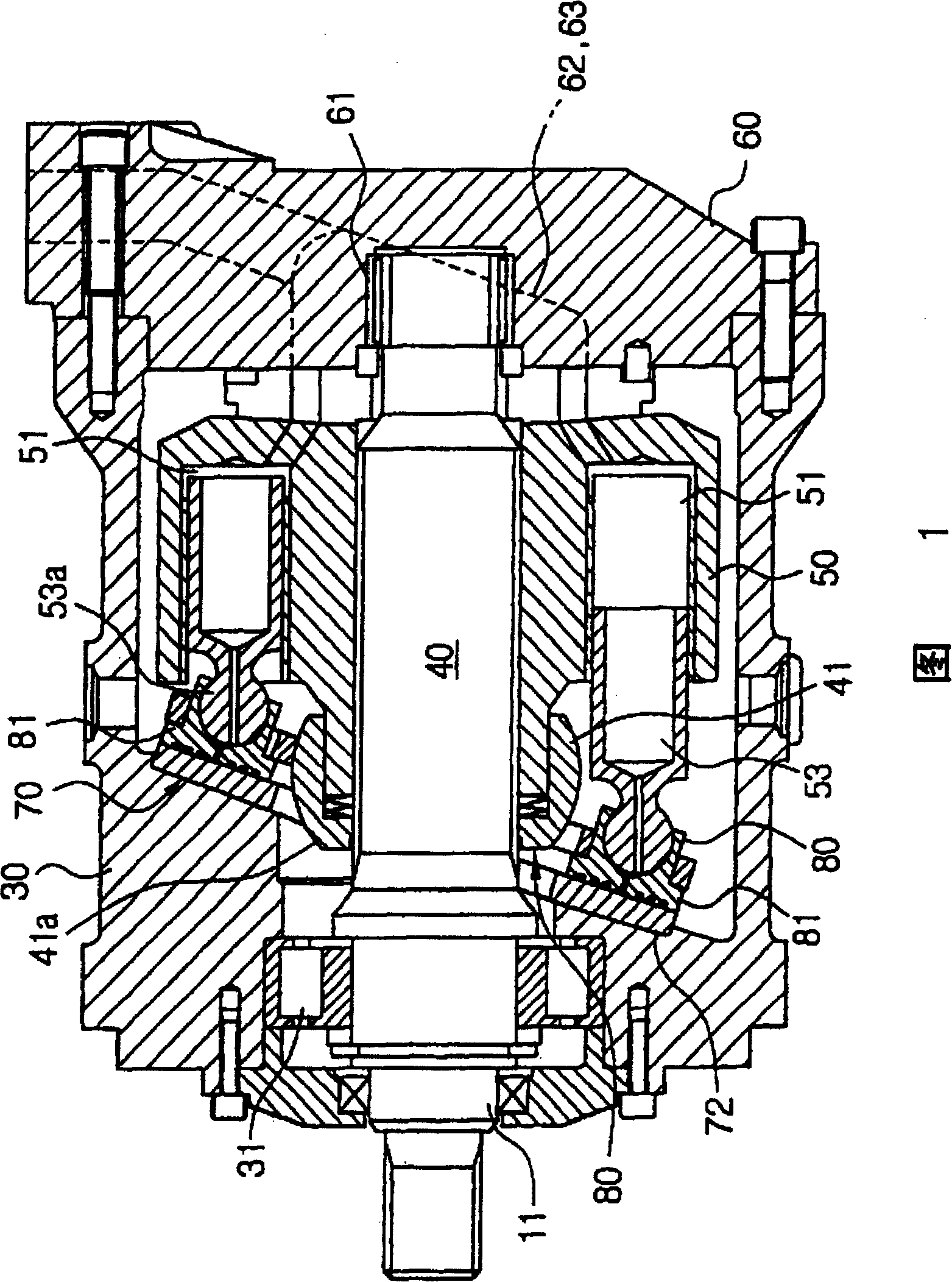

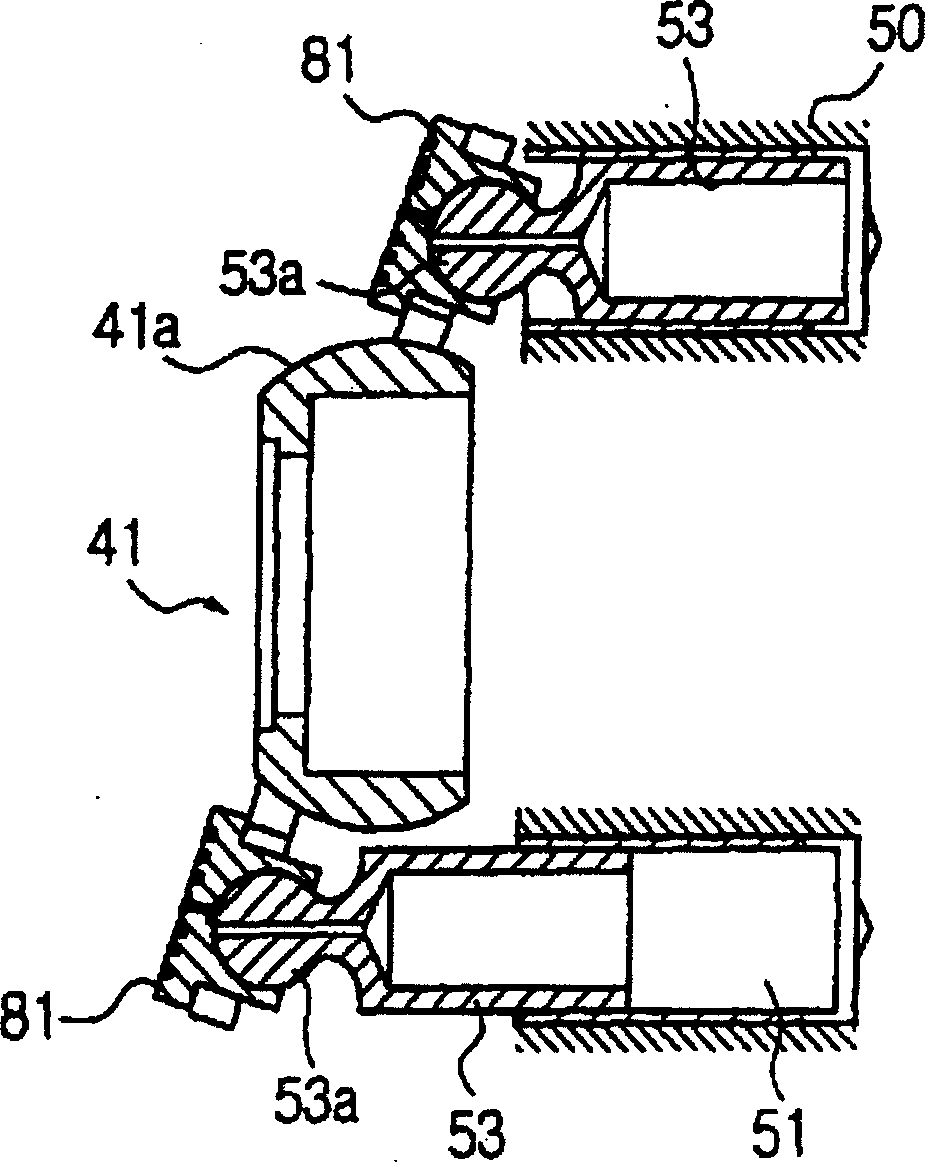

[0062] Fig. 5 is a longitudinal sectional view showing the internal structure of the variable variable swash plate type axial piston device of the present invention, and the parts that are the same as the conventional structural elements are marked with the same symbols.

[0063] In Fig. 5, reference numeral 20 denotes a housing of a variable variable swash plate type axial piston device.

[0064] The casing 20 includes: a bearing assembly 30 for axially supporting the rotating shaft 40 , an oil cylinder 50 rotating simultaneously with the rotating shaft, and a fluid flow tube composed of a multi-channel pipe for the fluid to flow into or out of the oil cylinder 51 of the oil cylinder 50 . The flow path assembly 60 is a cylindrical body 10 having a cylindrical cavity 10a in which the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com