Single-line arrangement development processing apparatus

A processing device and word arrangement technology, applied in photography, optics, instruments, etc., can solve problems such as different heat transfer coefficients, uneven development, and large-scale devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

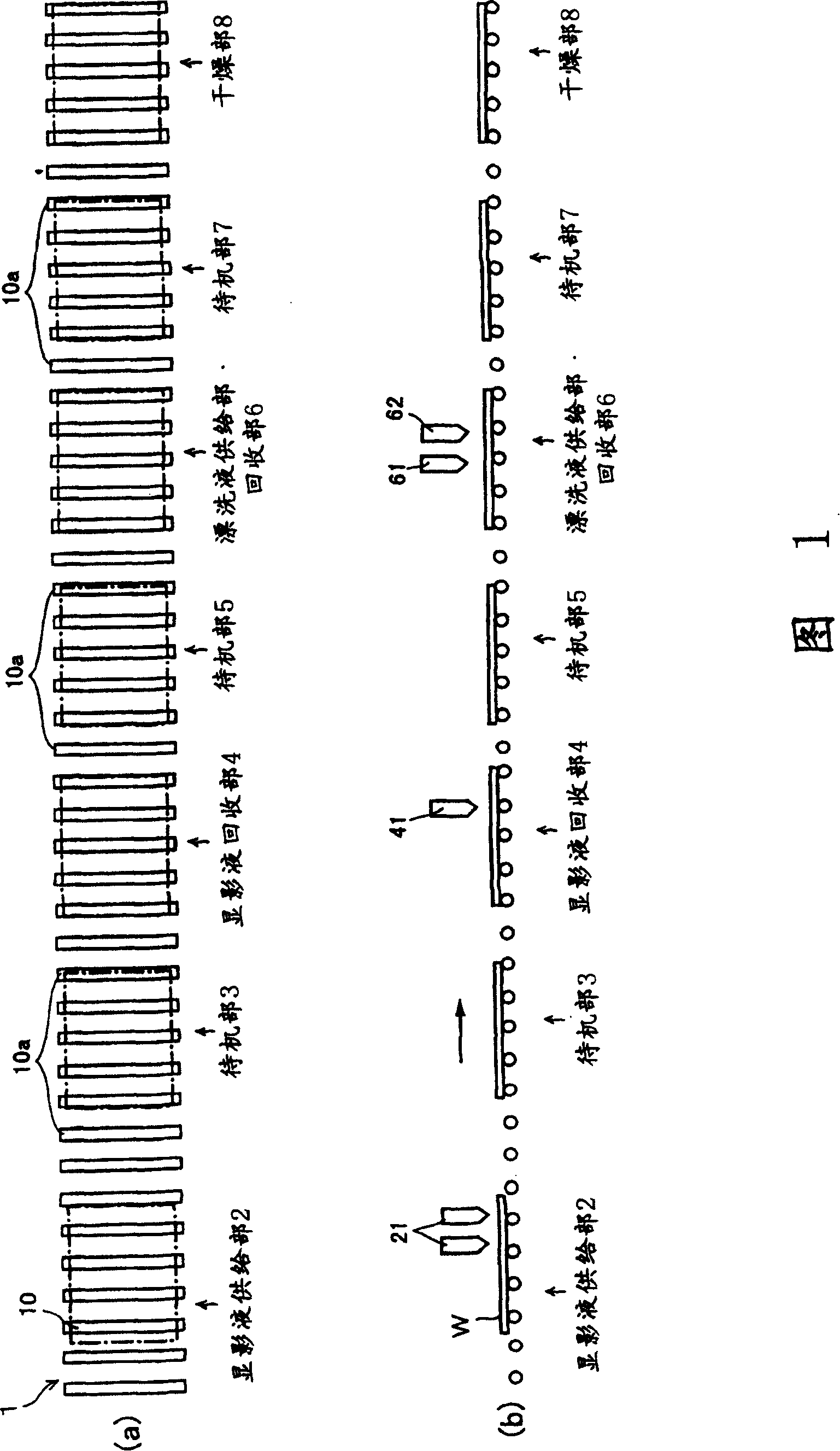

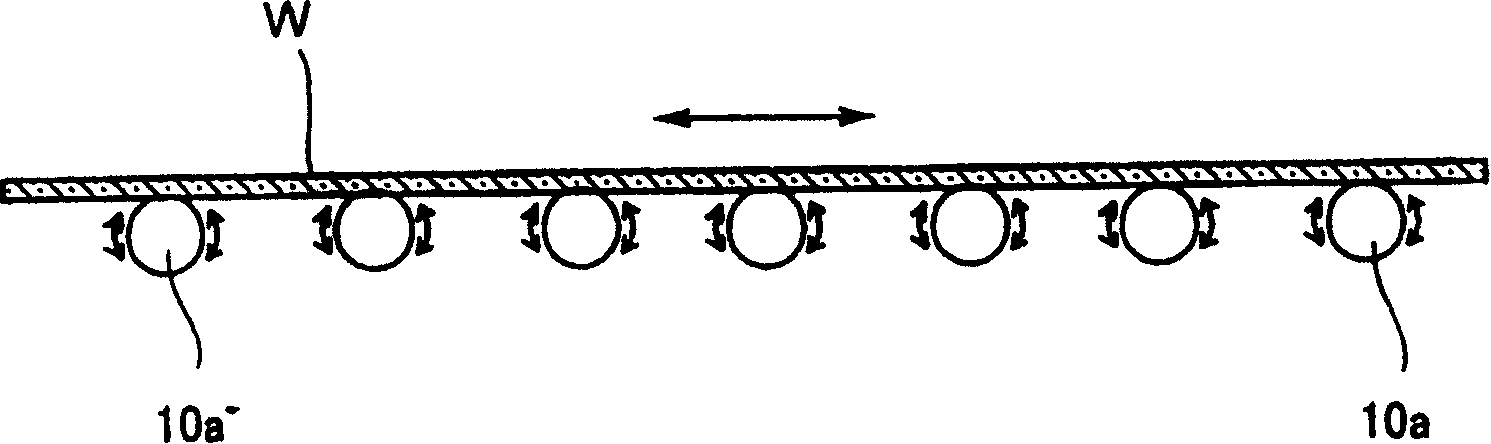

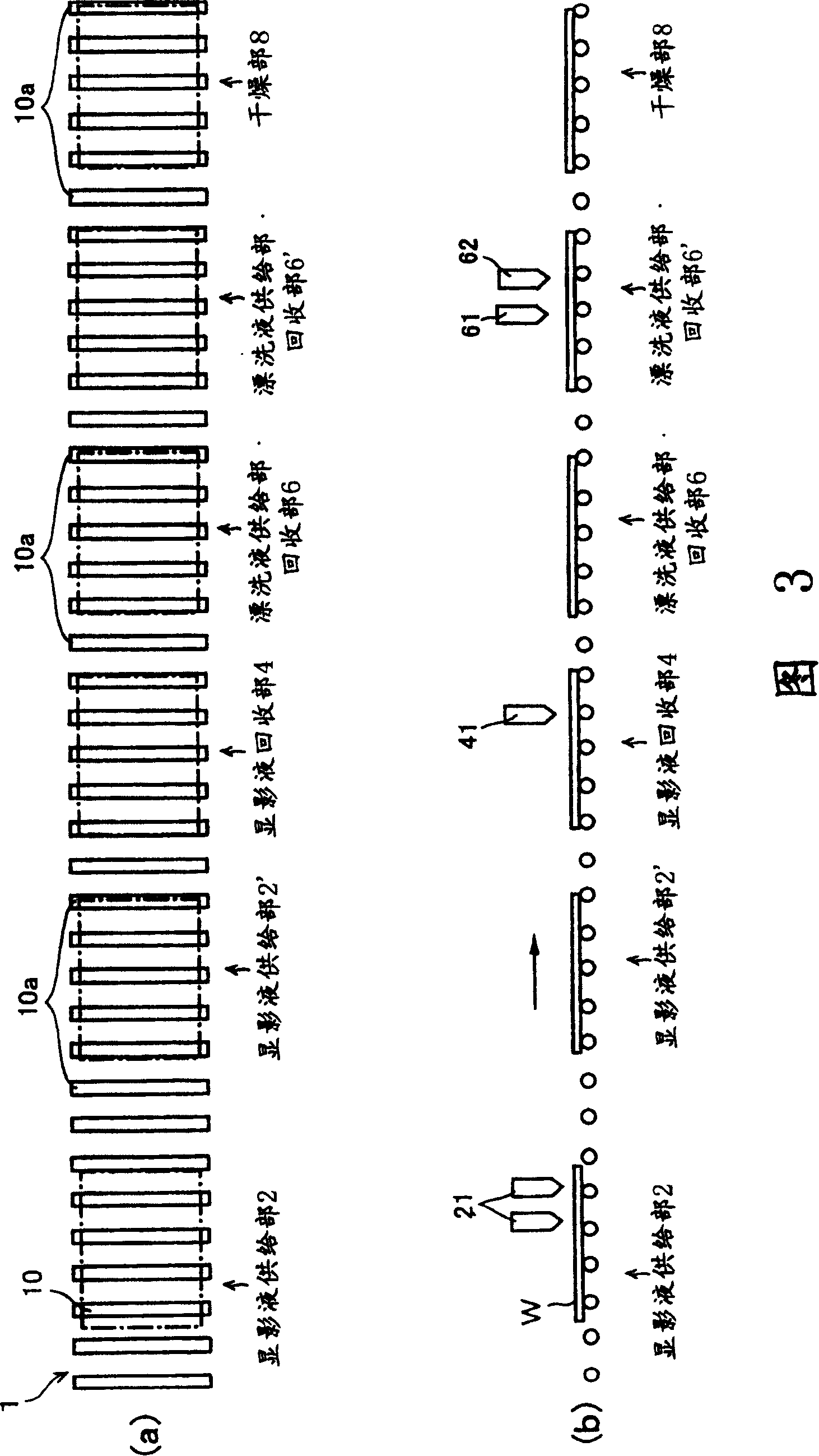

[0022] Embodiments of the present invention will be described below with reference to the drawings. Here, FIG. 1(a) and FIG. 1(b) are a plan view of a developing device according to the present invention and a side view thereof, respectively, figure 2 3(a) and 3(b) are plan views and side views thereof according to another embodiment of the present invention.

[0023] The in-line developing device is arranged in sequence from the upstream side along the substrate conveying line 1 with a developer solution supply unit 2, a standby unit 3, a developer solution recovery unit 4, a standby unit 5, a rinse solution supply / recovery unit 6, and a standby unit 7. In the drying section 8, a plurality of rollers (cylindrical rollers) 10 constituting the conveying line 1 are spaced at equal intervals and their axes are arranged in a direction perpendicular to the conveying direction of the substrate.

[0024] In addition, in the illustrated example, a standby unit is provided before vari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com