Direct laminated floor

一种产品、图案的技术,应用在层压产品领域,能够解决表面纹理图样视觉和触觉错误、不能逼真地模仿天然产品、不能很好地耐磨等问题,达到产品寿命延长的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] An embodiment of the present invention is described below, but it is not restrictive.

[0028] Typically, products in this form have a cellulose core impregnated with a polymer resin (eg phenol), especially melamine. The core may comprise wood or other products that are wear resistant, such as silica.

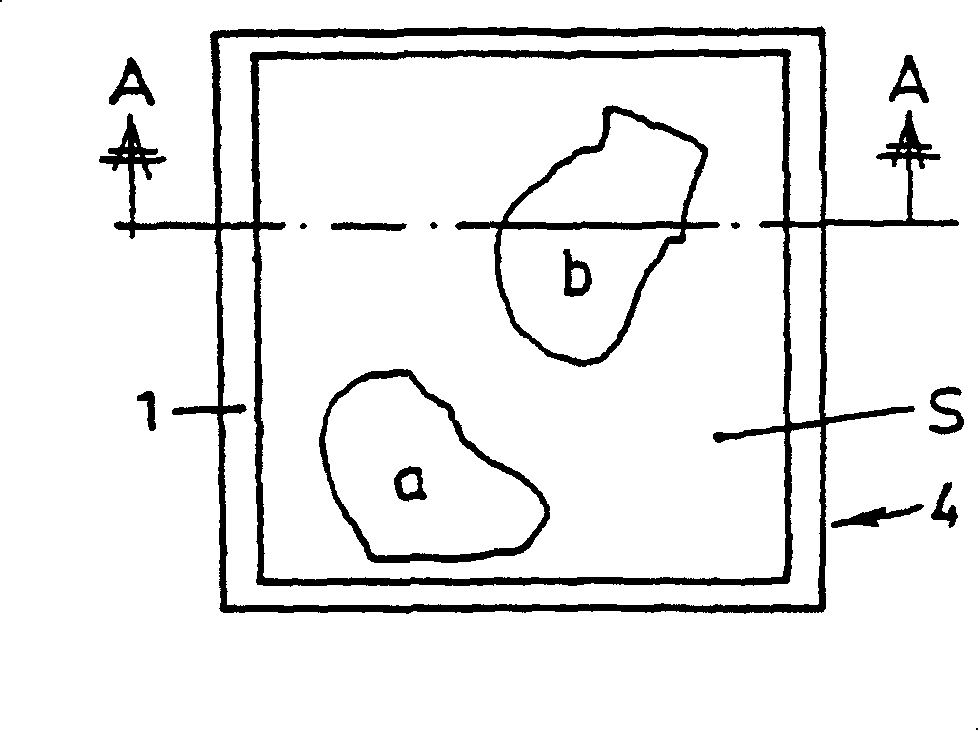

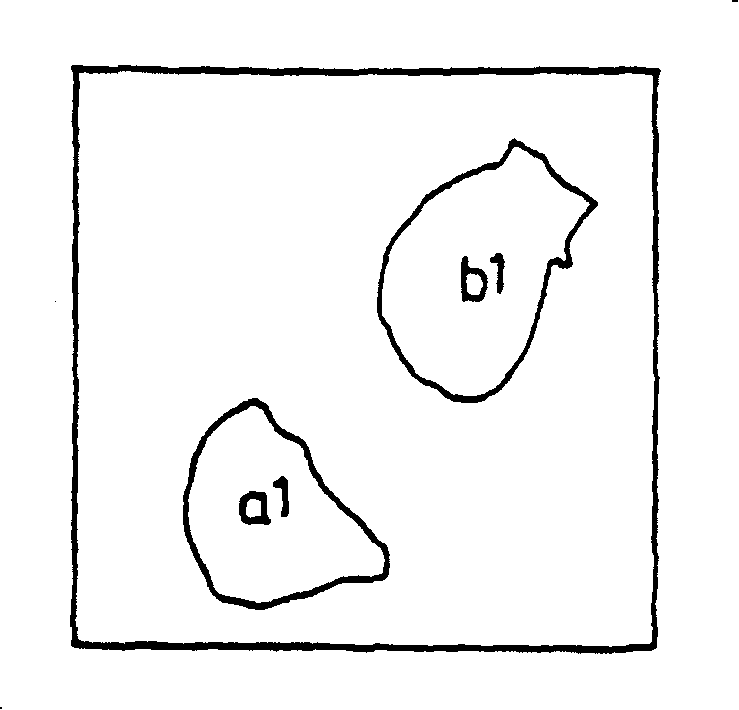

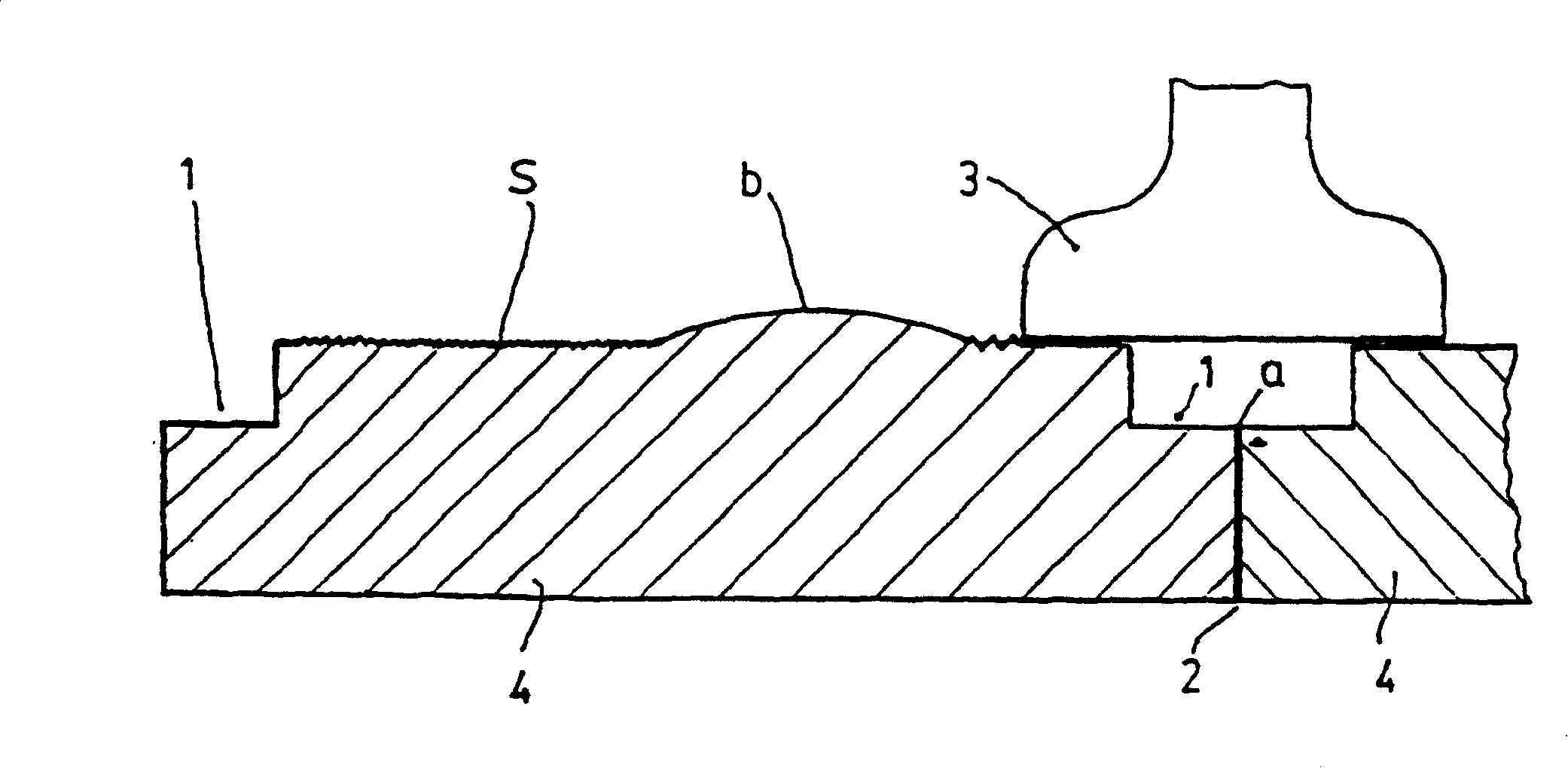

[0029] like figure 1 As shown, the product has an edge area. The color of this edge area is different from the rest of the product. After pressing, the edge is higher than the lower perimeter 1 (see figure 2 ).

[0030] see now figure 2 , the peripheral edge 1 of the pressed product unit 4 for paving is recessed below the rest S of the surface of the product unit. like image 3 As shown, the peripheral edge 1 forms a joint 2 . The joint 2 can be formed in a number of ways, such as tongue and groove.

[0031] The (mechanical) cutting or quartering of the initial sheet can be carried out by a press, cutting it into units (strips) of, for example, 300 x 300 mm or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com