Chuanxiong rhizome volatile oil soft capsule and its preparation method

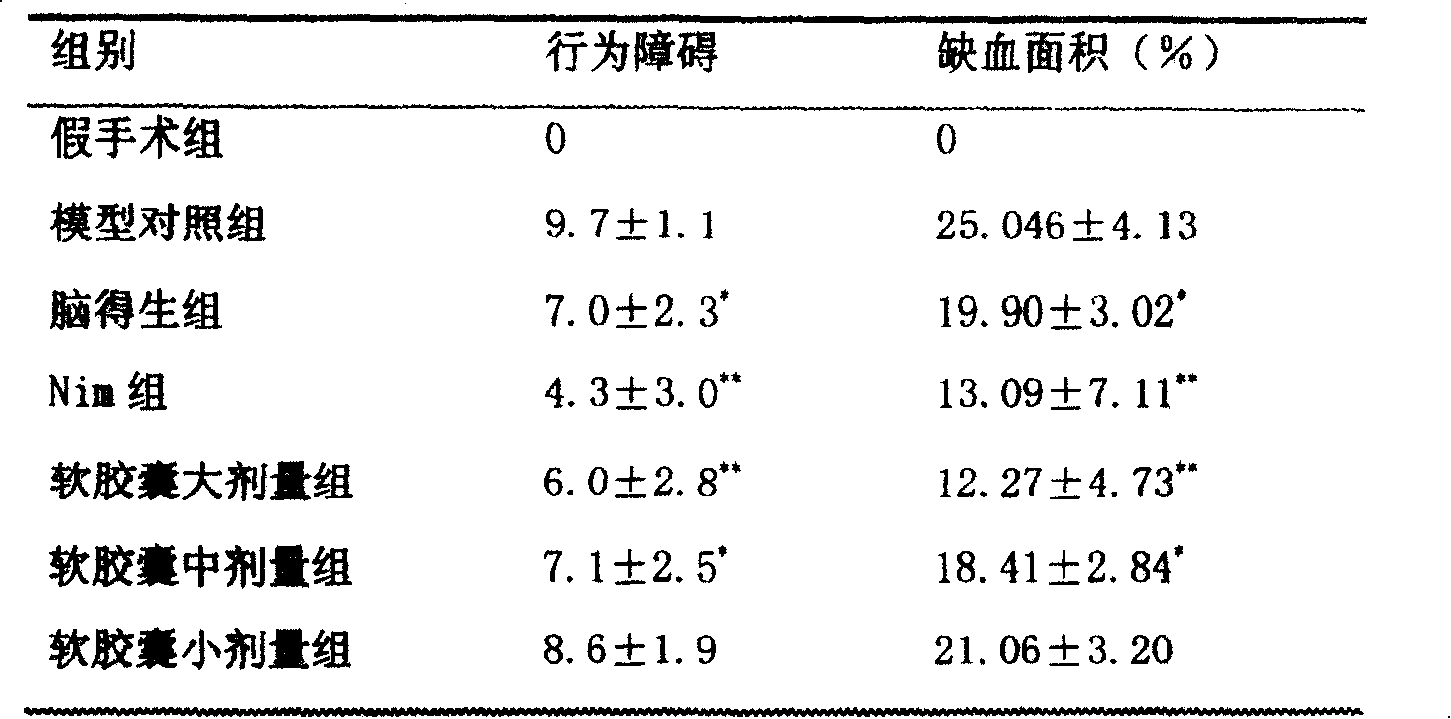

A technology of Chuanxiong volatile oil and soft capsules, which can be used in capsule delivery, pharmaceutical formulations, edible oil/fat, etc. It can solve problems affecting the efficacy of drugs, increase arterial blood flow, reduce necrosis area, and reduce cerebrovascular resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0014] Preparation Example 1: Preparation of Chuanxiong Oil Soft Capsules

[0015] A Chuanxiong oil preparation: 120 kilograms of dried Chuanxiong raw materials are crushed and passed through a No. 2 sieve, placed in a 600L supercritical extraction equipment for extraction, the extraction pressure is 10MPa, the extraction temperature is 40°C, the extraction time is 4 hours, CO 2 The flow rate is 20Kg / Kg Ligusticum chuanxiong·h, the pressure of the first stage separation tank is 8MPa, the temperature is 35°C, the extract is filtered, the filtrate is left to stand, and the oil layer is obtained.

[0016] Preparation of B gelatin solution: 100 g of gelatin, 60 g of glycerin and 100 g of water. Get gelatin and add appropriate amount of water to make it absorb water and swell. In addition, put the glycerin and the remaining water in a glue pot and heat to 70-80°C, mix evenly, add the expanded gelatin, stir, melt, keep warm for 1-2 hours, let stand to make the foam float up, and sc...

preparation example 2

[0019] Preparation Example 2: Preparation of Soft Capsules

[0020] A Chuanxiong oil preparation; 120 kilograms of dried Chuanxiong raw materials are crushed and passed through No. 2 sieve, placed in 600L supercritical extraction equipment, and extracted. The extraction pressure is 8MPa, the extraction temperature is 30°C, the extraction time is 2 hours, CO 2 The flow rate is 10Kg / Kg Ligusticum Chuanxiong·h, the pressure of the first-stage separation tank is 4MPa, the temperature is 20°C, the extract is filtered, the filtrate is left to stand, and the oil layer is taken to obtain the product.

[0021] Preparation of B gelatin solution: 100 g of gelatin, 40 g of glycerin and 70 g of water. Get gelatin and add appropriate amount of water to make it absorb water and swell. In addition, put the glycerin and the remaining water in a glue pot and heat to 70-80°C, mix evenly, add the expanded gelatin, stir, melt, keep warm for 1-2 hours, let stand to make the foam float up, and scra...

preparation example 3

[0025] A Chuanxiong oil preparation: 120 kilograms of dried Chuanxiong raw materials are crushed and passed through a No. 2 sieve, placed in a 600L supercritical extraction equipment for extraction, the extraction pressure is 10MPa, the extraction temperature is 60°C, the extraction time is 12 hours, CO 2 The flow rate is 30Kg / Kg Ligusticum chuanxiong·h, the pressure of the first stage separation tank is 10MPa, the temperature is 40°C, the extract is filtered, the filtrate is left standing, and the oil layer is taken to obtain the product.

[0026] Preparation of B gelatin solution: 100 g of gelatin, 60 g of glycerin and 140 g of water. Get gelatin and add appropriate amount of water to make it absorb water and swell. In addition, put the glycerin and the remaining water in a glue pot and heat to 70-80°C, mix evenly, add the expanded gelatin, stir, melt, keep warm for 1-2 hours, let stand to make the foam float up, and scrape off the floating foam to clean White cloth filter,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com