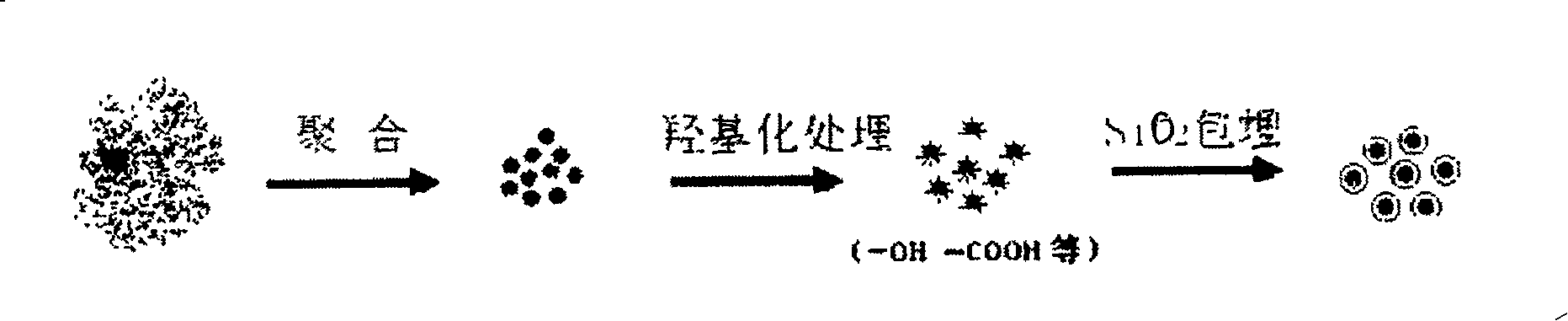

Method for preparing silicon dioxide embedded nano composite particles

A technology of composite particles and silica, applied in the direction of magnetic properties of inorganic materials, can solve the problems such as treating the symptoms but not the root cause, complex preparation steps, and large influence on the final product shape, and achieves smooth appearance, increased preparation amount, and narrow particle size distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

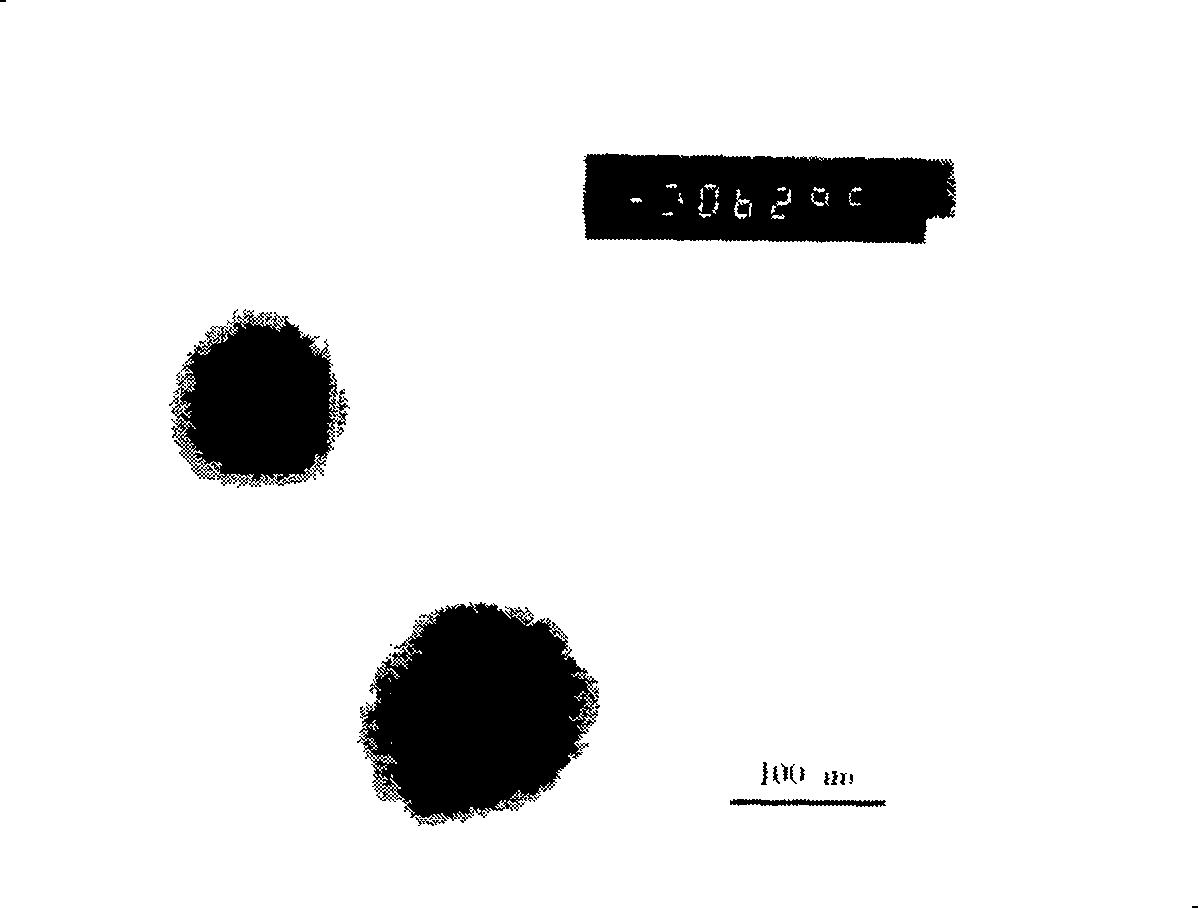

[0018] Embodiment 1: Utilize traditional co-precipitation method to prepare Fe respectively 3 o 4 , Fe 2 o 3 、CoFe 2 o 4 2.2 g of nanoparticles each. After the reaction, the obtained precipitate was separated from the reaction medium by applying an external magnetic field, and washed with water for 3 times.

Embodiment 2

[0019] Embodiment 2: Disperse any fresh nanoparticles prepared in Example 1 in 220mL methanol solution, and make a magnetic fluid suspension with a concentration of 10g / L, and add trimethoxy in a ratio of 0.1 gram per gram of magnetic nanoparticles propenyl silane (MPS), the solution was heated and refluxed for 4 hours, after the solution was cooled to room temperature, the precipitate was centrifuged, and the precipitate was washed alternately with water and ethanol for three cycles, and then the precipitate was dispersed in the ethanol solution to obtain MPS- Magnetic nanoparticles ethanol solution;

Embodiment 3

[0020] Embodiment 3: Disperse any fresh nanoparticles prepared in Example 1 in 220mL aqueous solution, and make a magnetic fluid suspension with a concentration of 10g / L. By the nitrogen degassing method of the prior art, the suspension will Degas for 20 minutes. Then, the prepared magnetic fluid suspension was heated to 80°C, and 3 mL of oleic acid was added dropwise at a stirring speed of 800 rpm, followed by the addition of 1 mL of ammonia water. Leave it for half an hour. Finally, the precipitate was collected by centrifugation, and the precipitate was alternately washed with water and ethanol for three cycles, and the precipitate was dispersed in the ethanol solution to obtain the oleic acid-magnetic nanoparticle ethanol suspension.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com