Injection pretreatment method for oil water well

A pretreatment, oil-water well technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve problems such as rapid rise in injection pressure, oil layer damage, low recovery degree, etc., to delay energy decline , The effect of removing formation blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0018] Experimental Example 1 Scale Analysis and Countermeasures

[0019] 1. Scale composition

[0020] We selected the scale samples from the Qian’an water injection well, and after calcination and acid solution dissolution, the scale composition was measured as follows: Table 1

[0021] Scale composition

Organic fouling (%)

Inorganic scale (%)

Acid insoluble matter (%)

Scale 1#

21.56%

76.30%

2.14%

Dirty sample 2#

42.60%

54.77%

2.63%

[0022] 2. Countermeasures taken

[0023] According to the analysis results of scale samples in Qian'an area, it can be seen that there are three types of substances in the scale samples: organic scale, inorganic scale and acid insoluble substances. For the composition of these scales, we have adopted different indoor tests based on the field and the experience of acidification measures over the years.

[0024] (1) Tests for organic fouling

[0025] Weigh the scale...

experiment example 2

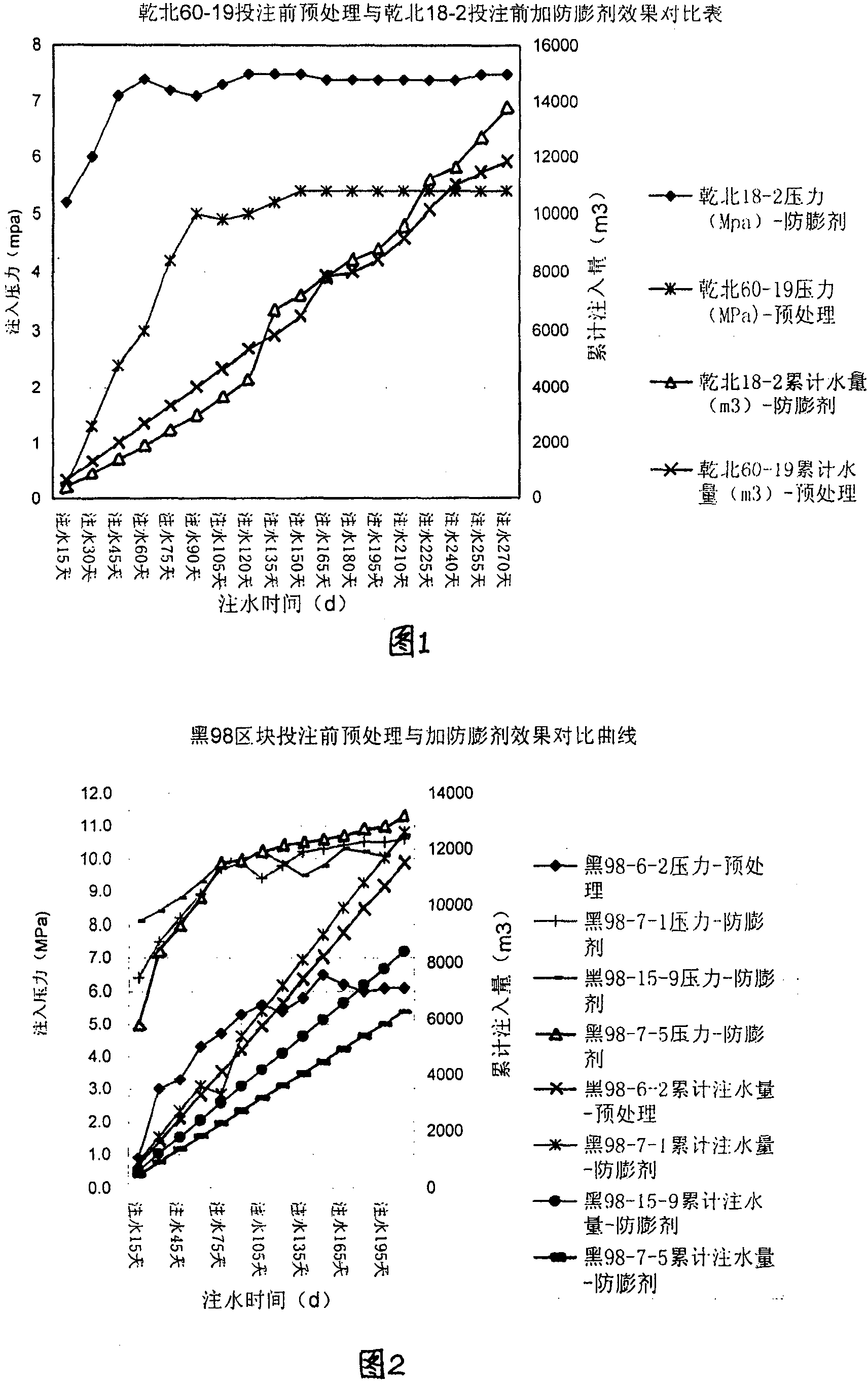

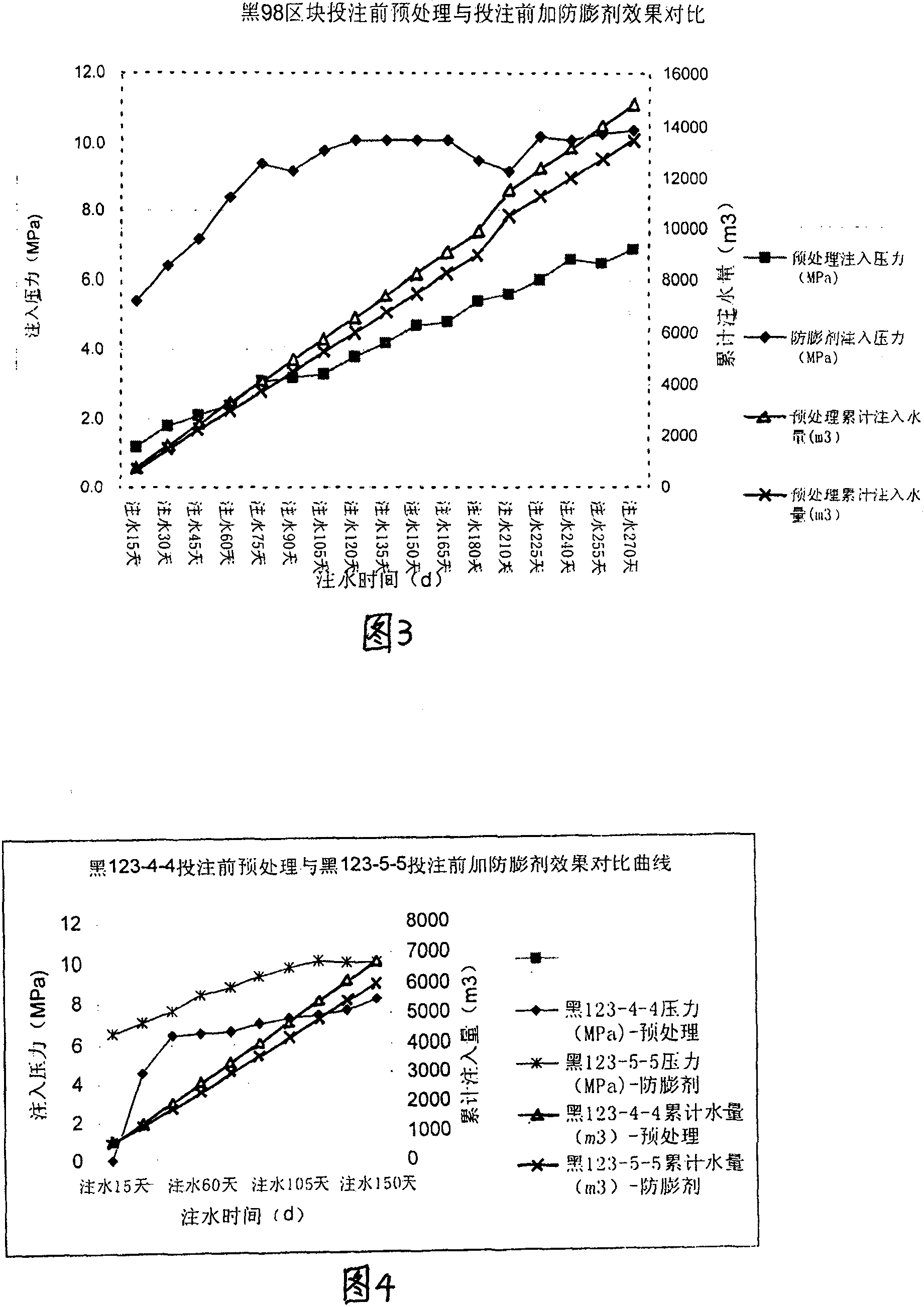

[0067] 6 wells were selected for pretreatment before injection, and 12 wells were squeezed with anti-swelling agent. Statistical results show that: the initial injection pressure of wells using pre-injection pretreatment technology is 3.5 MPa lower than that of wells squeezed with anti-swelling agent.

[0068]

experiment example 3

[0070] In addition, 4 wells with comparable pretreatment before injection were selected, and 8 wells were squeezed with anti-swelling agent. Statistical results show that the initial injection pressure of wells using pre-injection pretreatment technology is 5.3MPa lower than that of wells squeezed with anti-swelling agent, and the pressure is still 3.9MPa lower after 120 days of water injection.

[0071] project

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com