Wave plate shape bag type dust collector

A technology of bag filter and corrugated plate, applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of increasing raw material costs, lack of mineral resources, waste of raw materials for reinforced steel, etc., to reduce production Cost and labor costs, high degree of production mechanization, and the effect of quality assurance on appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

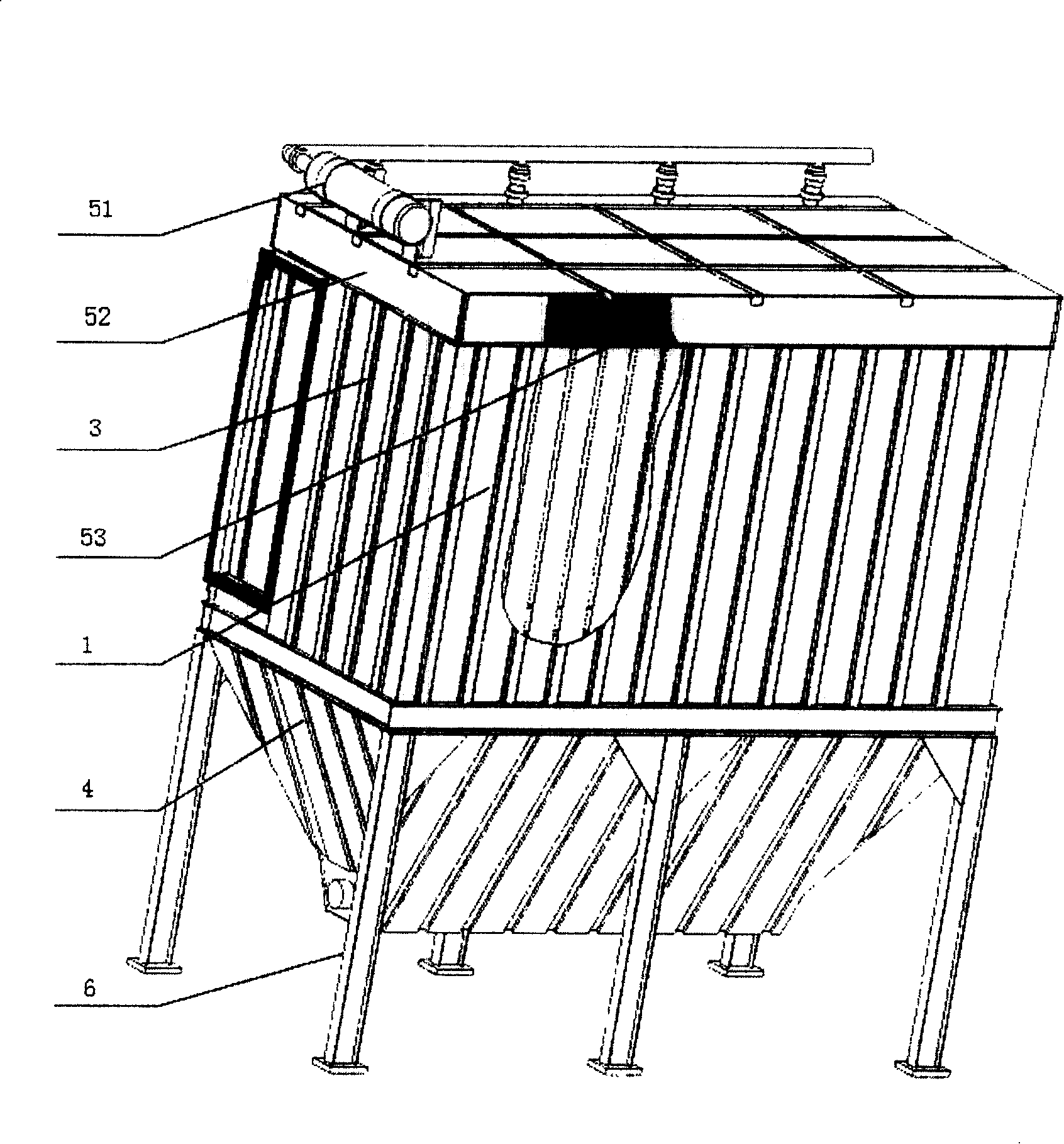

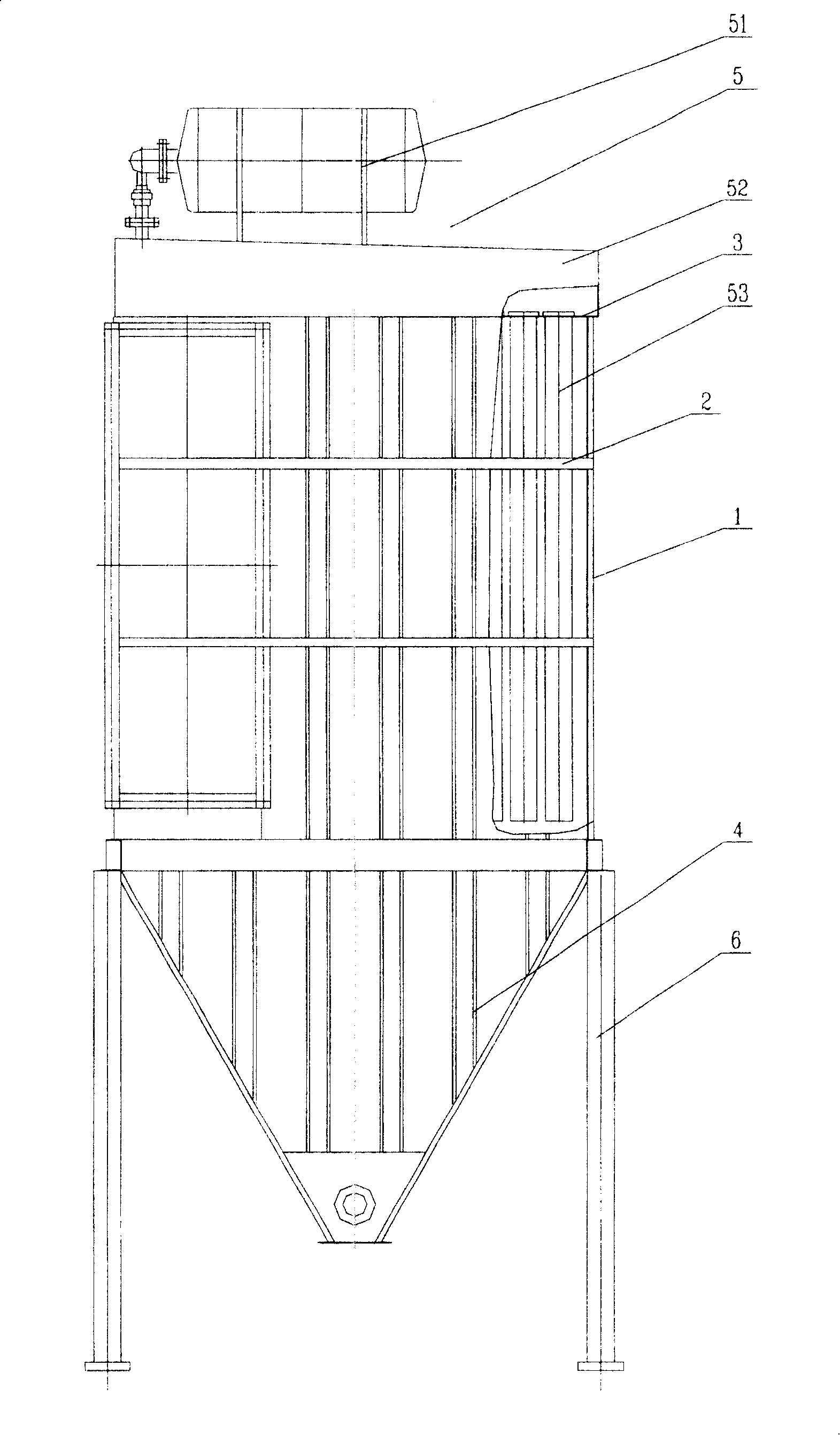

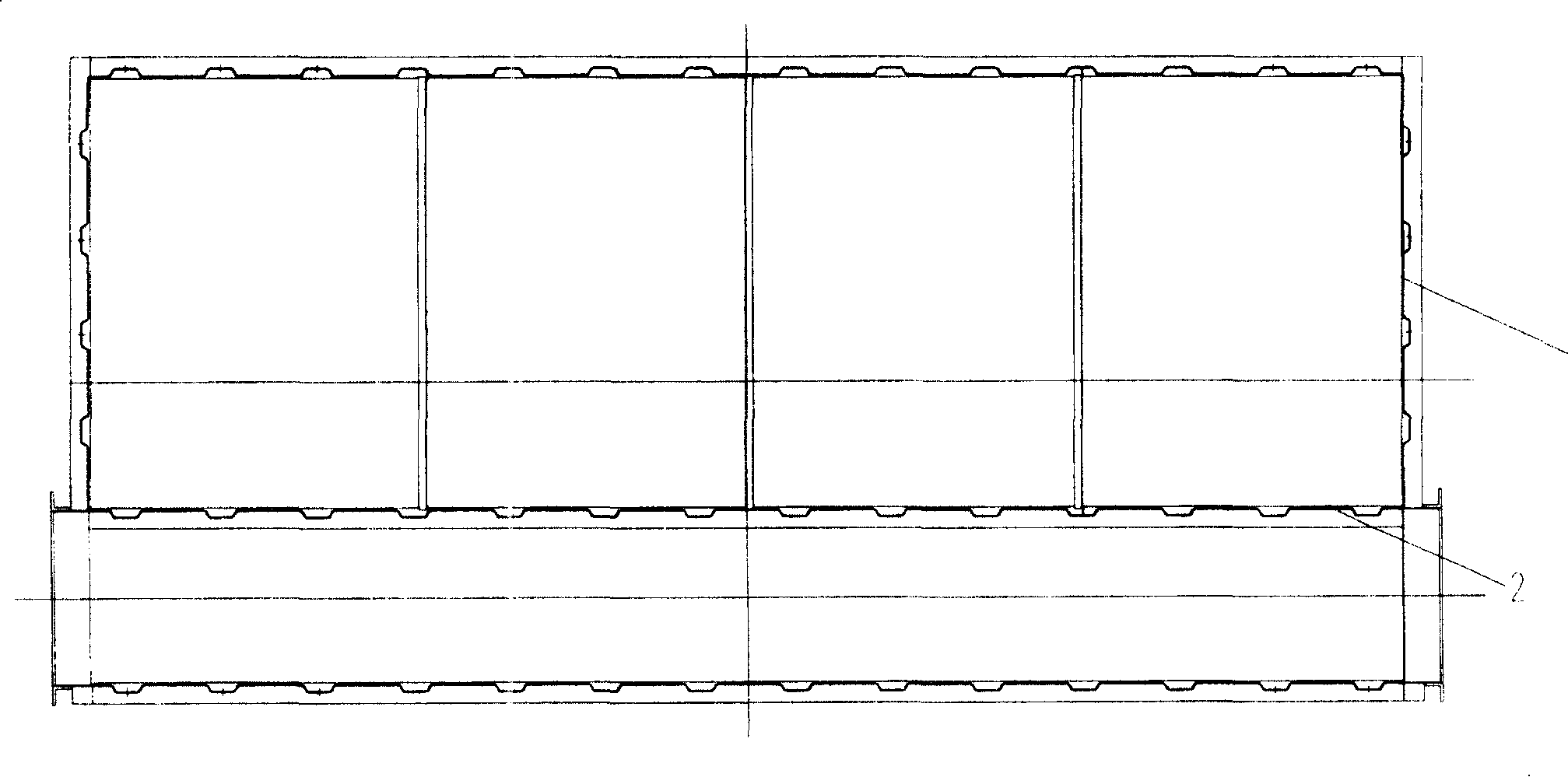

[0018] like figure 1 Shown is a perspective view of the wave plate type bag filter of the present invention; including but not limited to the box shell plate 1, a number of partition plates 2 separating the box shell plate 1, and the flowers corresponding to the partition plate 2 Plate 3, ash hopper 4 and pulse dust removal assembly 5 connected with box shell plate 1, said box shell plate 1 adopts profiled steel plate, and profiled steel plate is trapezoidal corrugated plate. The box shell plate 1, partition plate 2 and ash hopper 4 of the bag filter must withstand a pressure of 6000-14000 Pa during the dust-gas filtration and dust-cleaning operation; In this way, it is difficult to realize the automatic and high-efficiency production of dust collectors. like image 3 Shown is a structural schematic diagram of the box shell plate and the partition plate of the wave plate type bag filter of the present invention. The present invention adopts special-purpose corrugated profil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com