Method for synthesizing beta zeolite in small crystal grain

A technology of beta zeolite and small crystal grains, which is applied in the field of synthesizing small crystal grains of beta zeolite, can solve the problems of low yield of molecular sieves, and achieve the effects of low template dosage, reduced production cost, and shortened crystallization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

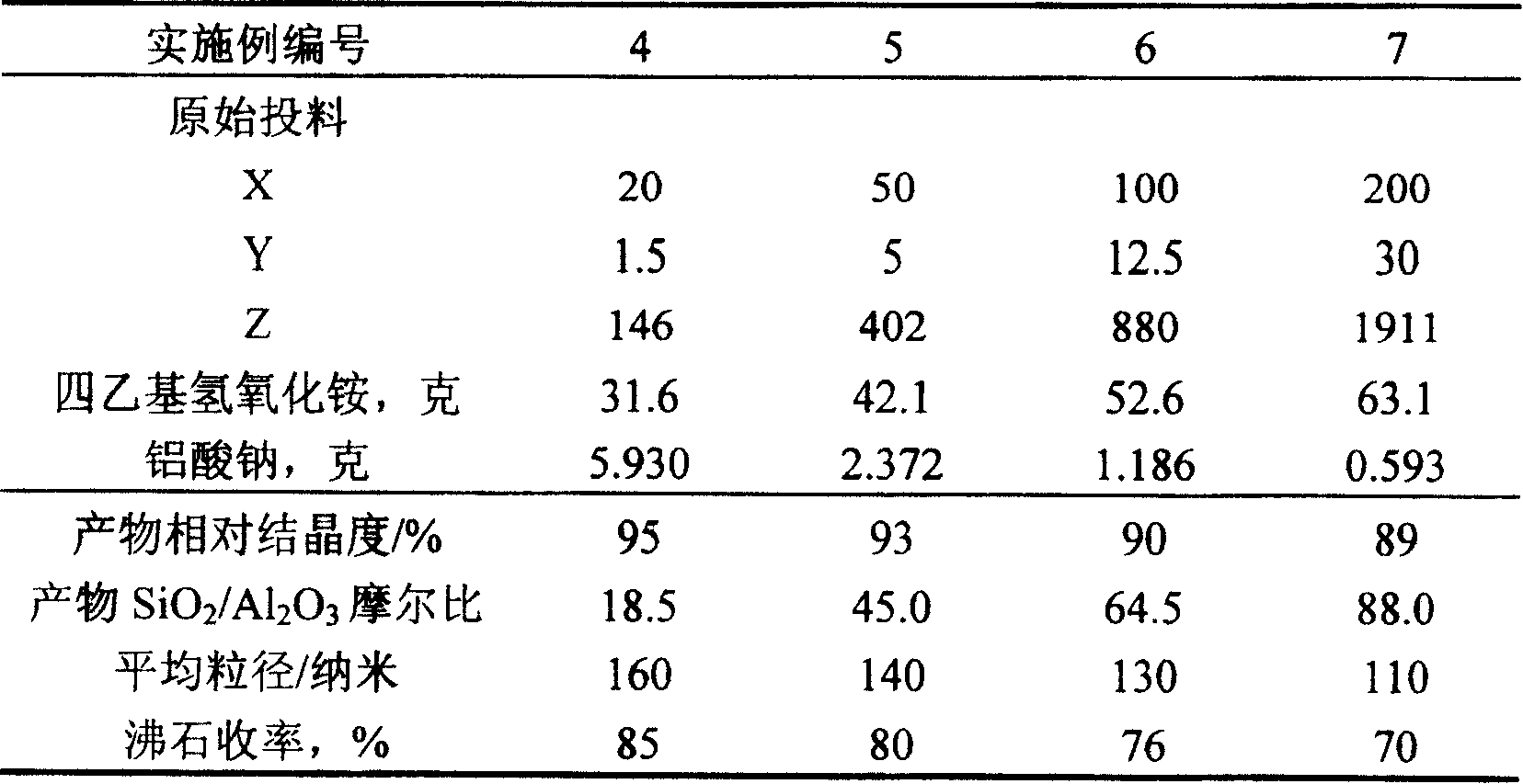

Examples

preparation example Construction

[0023] Preparation of zeolite beta reference

[0024] A beta zeolite reference was synthesized following the method disclosed in the examples in US3308069.

[0025] In 26.2 grams of 25% by weight TEAOH (commercially available), add 1.05 grams of sodium aluminate (containing Al 2 o 3 43% by weight, containing Na 2 (39% by weight, industrial product), then add 38.8 grams of silica sol (containing SiO 2 26% by weight, industrial product), stirring was continued for 1 hour. Transfer to a stainless steel reaction kettle, crystallize at 150°C for 3 days, take it out and cool, filter, wash, and dry at 140°C to obtain zeolite beta.

[0026] The mol ratio of feeding each component is:

[0027] 1Al 2 o 3 ·38SiO2 2 5 (TEA) 2 O·1.5Na 2 O·532H 2 o

[0028] Taking this sample as a reference sample, the crystallinity measured by XRD is taken as 100%. The crystallinity of the examples of the present invention and the comparative samples are compared with the reference sample by ...

Embodiment 1~3

[0049] According to the method provided by the invention to synthesize small-grain beta zeolite

[0050] Raw material is

[0051] (A), silica sol: containing SiO 2 40% by weight, industrial product.

[0052] (B), sodium aluminate: containing Al 2 o 3 43% by weight, a commercially available product.

[0053] (C), tetraethylammonium hydroxide: content 35% by weight, industrial product.

[0054] (D), sodium fluoride, content 98% by weight, commercially available.

[0055] Take 2.143 grams of sodium fluoride and dissolve it in 42.1 grams of tetraethylammonium hydroxide solution, add 2.372 grams of sodium aluminate and 75 grams of silica sol under stirring, after stirring evenly, transfer it to a stainless steel reaction kettle, and carry out crystallization according to a certain heating program. reaction. The crystallization temperatures are 120, 100, and 80°C, respectively. Suction filtration, washing, and drying are carried out after crystallization. X-ray diffraction...

Embodiment 1

[0059] The XRD diffraction results of the zeolite beta prepared in Example 1 are shown in Table 2.

[0060] Table 2

[0061] 2θ

[0062] By adopting the method of the invention, the synthesized zeolite does not contain miscellaneous crystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com