Timber selecting and chopping method and selection chopping saw therefor

A technology for cutting saws and timber, which is applied in the direction of circular saws, unloading equipment, sawing equipment, etc., which can solve the problems of limiting sawing production efficiency and increasing wood output rate, inability to automate continuous production, and low per capita labor productivity, etc. problems, to achieve the effect of shortening consumption and waste, avoiding waste, and improving operation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

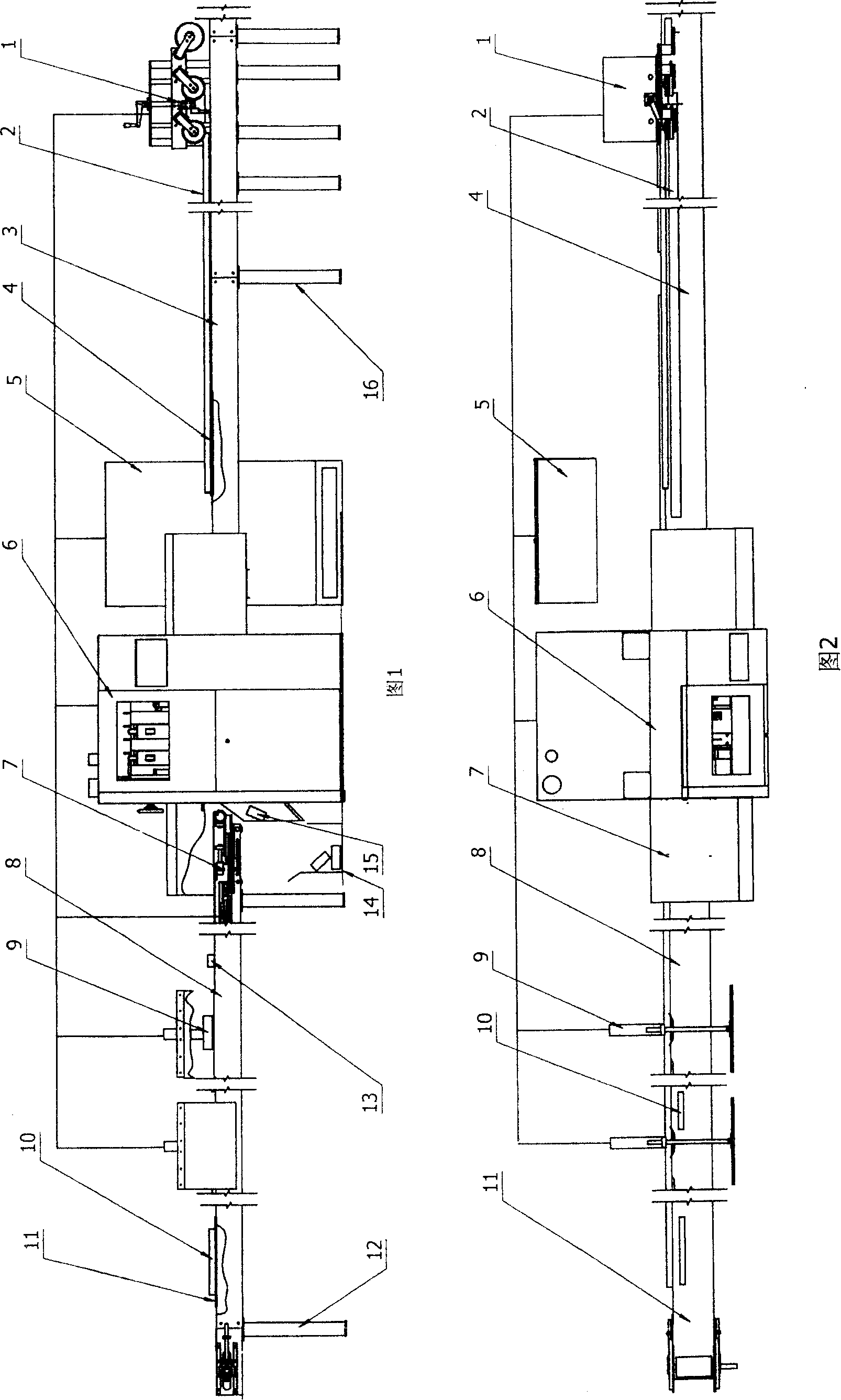

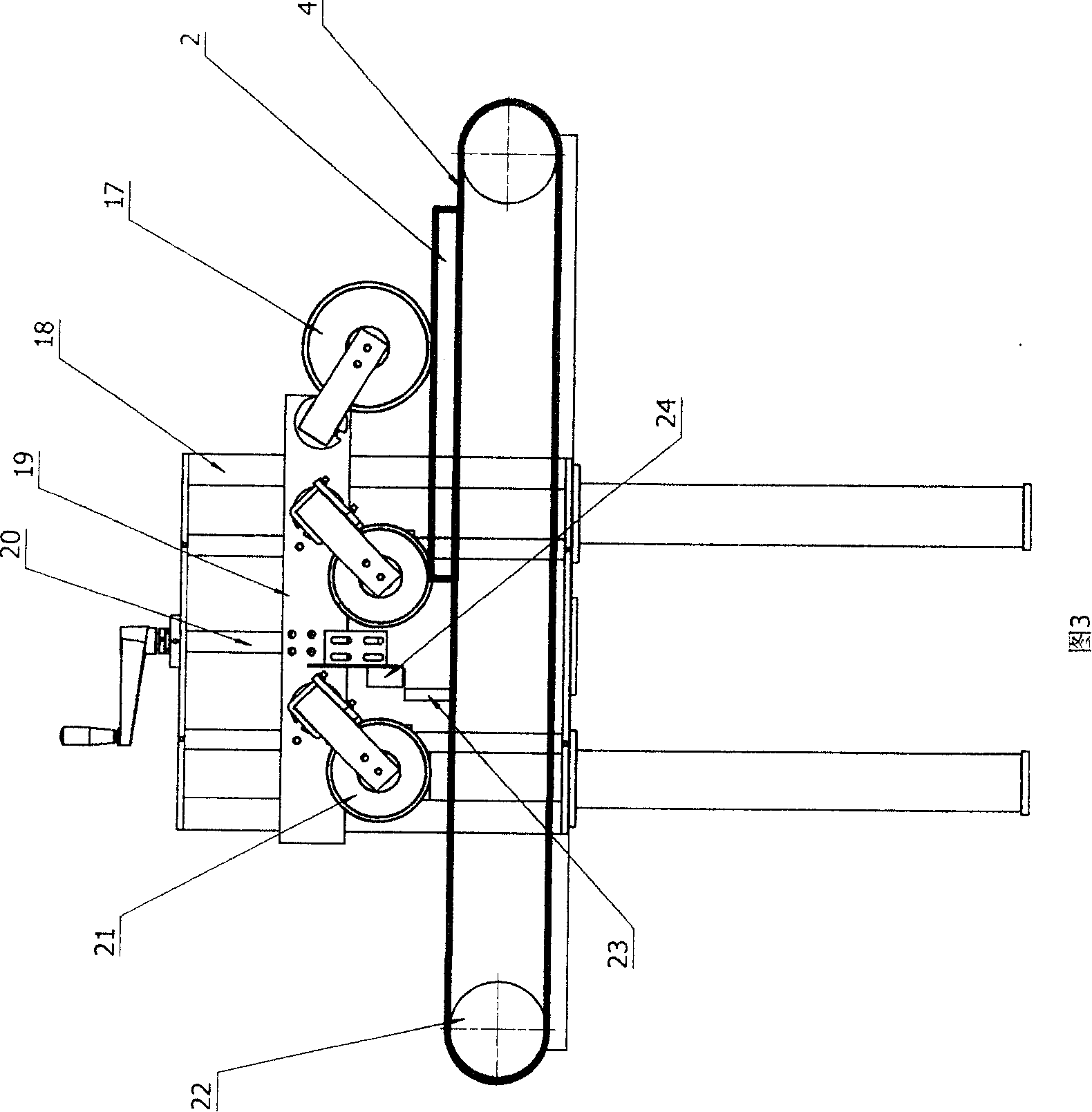

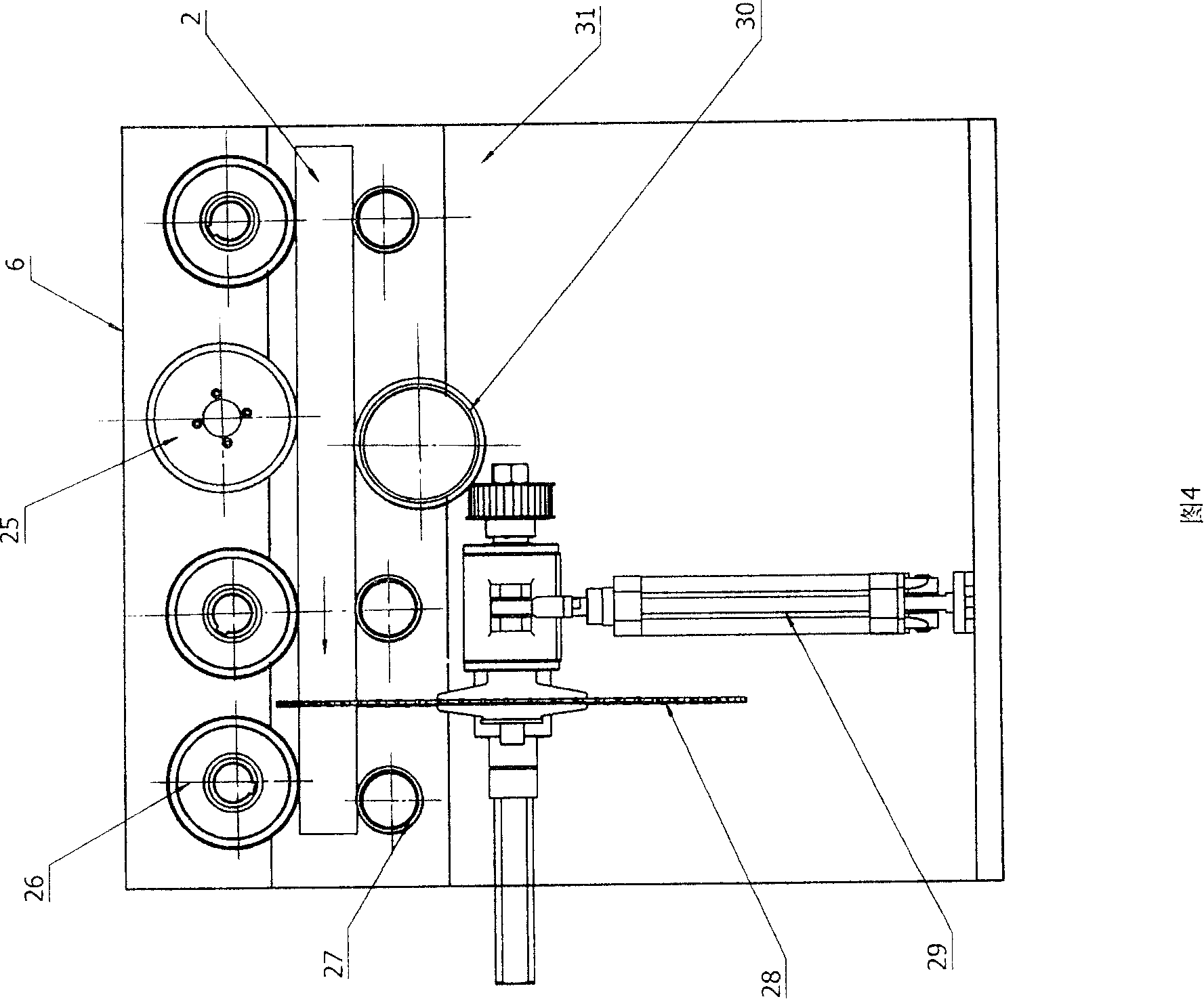

[0027] As shown in Fig. 1, the timber preferred cut-off method of the present invention, at first according to actual processing requirement, input the sawing data list that comprises required target sawn timber length and quality parameter in computer device 5 in advance, in this input data list also Including the speed, acceleration, deceleration of the servo motor, the speed ratio between the motors and the thickness of the saw blade and other parameters; 2 From the corresponding position of the detection device 1 to the sawing kerf of the sawing machine 6 without relative misalignment, the detection device 1 can accurately and timely read the length, quality and defect information of the wood to be sawn 2, and transmit these timely information to the computer Device 5; the computer device 5 selects and determines the best sawing plan according to the list of sawing data input in advance and the information of the wood to be sawed read by the detection device 1, and the best...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com