No-shrinkage grouting filler with adjustable performance

A grouting material and adjustable technology, which is applied in the field of grouting material for basic engineering and non-shrinking grouting material, can solve the problems that the grouting material cannot fill the entire space, the base of the equipment is loose, and the fluidity is not enough, and achieves low brittleness and fluidity. Good, little creep effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

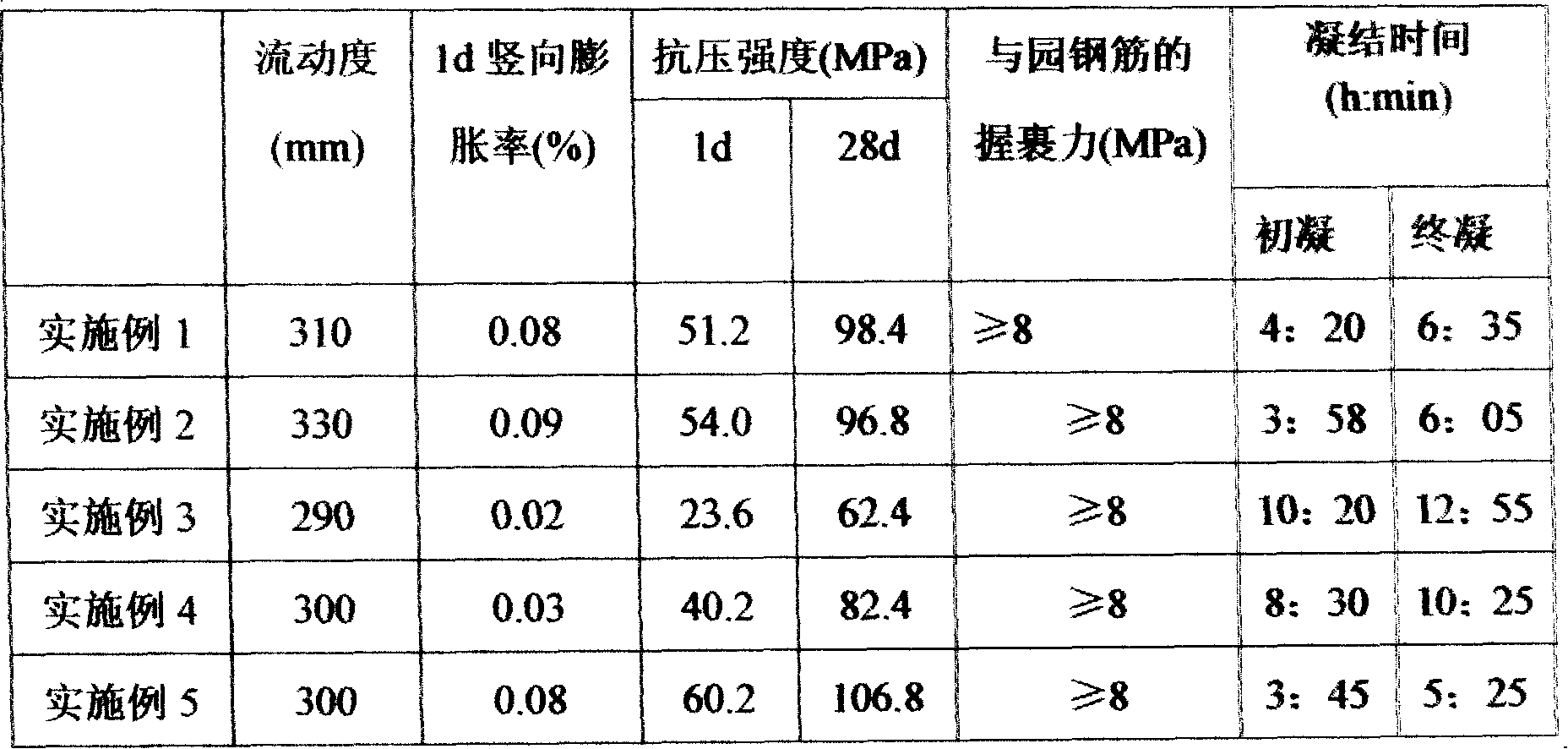

Examples

Embodiment 1

[0027] Embodiment 1, a kind of performance-adjustable non-shrinkage grouting material,

[0028] The grouting material is composed of cementitious material, quartz sand and a small amount of water reducing agent, expansion agent, water loss reducing agent, anti-early settlement agent, anti-early shrinkage agent and mixing water. The ratio of various materials is:

[0029] PO42.5R cement 40.5%;

[0030] Fly ash 6.1%;

[0031] Quartz sand 49%;

[0032] The gradation of quartz sand is:

[0033] 0.0~0.16mm 9% (by weight)

[0034] 0.16~0.315mm 35% (weight ratio)

[0035] 0.3 15~1.25mm 28% (weight ratio)

[0036] 1.25~2.5mm 18% (weight ratio)

[0037] 2.5~3.0mm 10 (weight ratio)

[0038] Naphthalenesulfonate formaldehyde condensate and sulfamate mixture 1.28%, the ratio of naphthalenesulfonate formaldehyde condensate and sulfamate is: 3:1.

[0039] Burnt quicklime and sulphoaluminate expansion agent 3.0%, the ratio of burnt quicklime and sulphoaluminate expansion agent is: 1:...

Embodiment 2

[0045] Example 2, a non-shrinkage grouting material with adjustable performance

[0046] The grouting material is composed of cementitious material, quartz sand and a small amount of water reducing agent, expansion agent, water loss reducing agent, anti-early settlement agent, anti-early shrinkage agent and mixing water. The ratio of various materials is:

[0047] PO42.5R type cement, 41.5%.

[0048] Fly ash, 7.4%.

[0049] Quartz sand, 47.5%.

[0050] The gradation of quartz sand is:

[0051] 0.0~0.16mm 8% (by weight)

[0052] 0.16~0.315mm 35% (weight ratio)

[0053] 0.315~1.25mm 30% (weight ratio)

[0054] 1.25~2.5mm 15% (weight ratio)

[0055] 2.5~3.0mm 12% (weight ratio)

[0056] Naphthalenesulfonate formaldehyde condensate and sulfamate mixture, 0.95%. (The ratio of naphthalenesulfonate formaldehyde condensate and sulfamate is: 3:1).

[0057] Burnt quicklime and sulphoaluminate expansion agent, 2.58%. (The ratio of overburned quicklime and sulphoaluminate expansio...

Embodiment 3

[0063] Embodiment 3, a kind of non-shrinkage grouting material with adjustable performance

[0064] The grouting material is composed of cementitious material, quartz sand and a small amount of water reducing agent, expansion agent, water loss reducing agent, anti-early settlement agent, anti-early shrinkage agent and mixing water. The ratio of various materials is:

[0065] PO42.5R type cement, 31.5%.

[0066] Ultrafine silica fume powder, 1.2%.

[0067] Fly Ash, 10%

[0068] Quartz sand, 54.3%.

[0069] The gradation of quartz sand is:

[0070] 0.0~0.16mm 8% (by weight)

[0071] 0.16~0.315mm 34% (weight ratio)

[0072] 0.315~1.25mm 29% (weight ratio)

[0073] 1.25~2.5mm 20% (weight ratio)

[0074] 2.5~3.0mm 9% (weight ratio)

[0075] Naphthalenesulfonate formaldehyde condensate, 1.0%.

[0076] Burnt quicklime and sulphoaluminate expansion agent, 1.83%. (The ratio of burnt quicklime and sulphoaluminate expansion agent is: 1:4.5)

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com