Water drop induction structure of elevating glass

A technology of glass and water droplets, which is applied to the windshield, the operating mechanism of the wing leaf, the manual mechanism, etc., can solve the problems of wear on the lip of the guide rail, increase the burden on the driving structure, and achieve the effect of reducing water splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

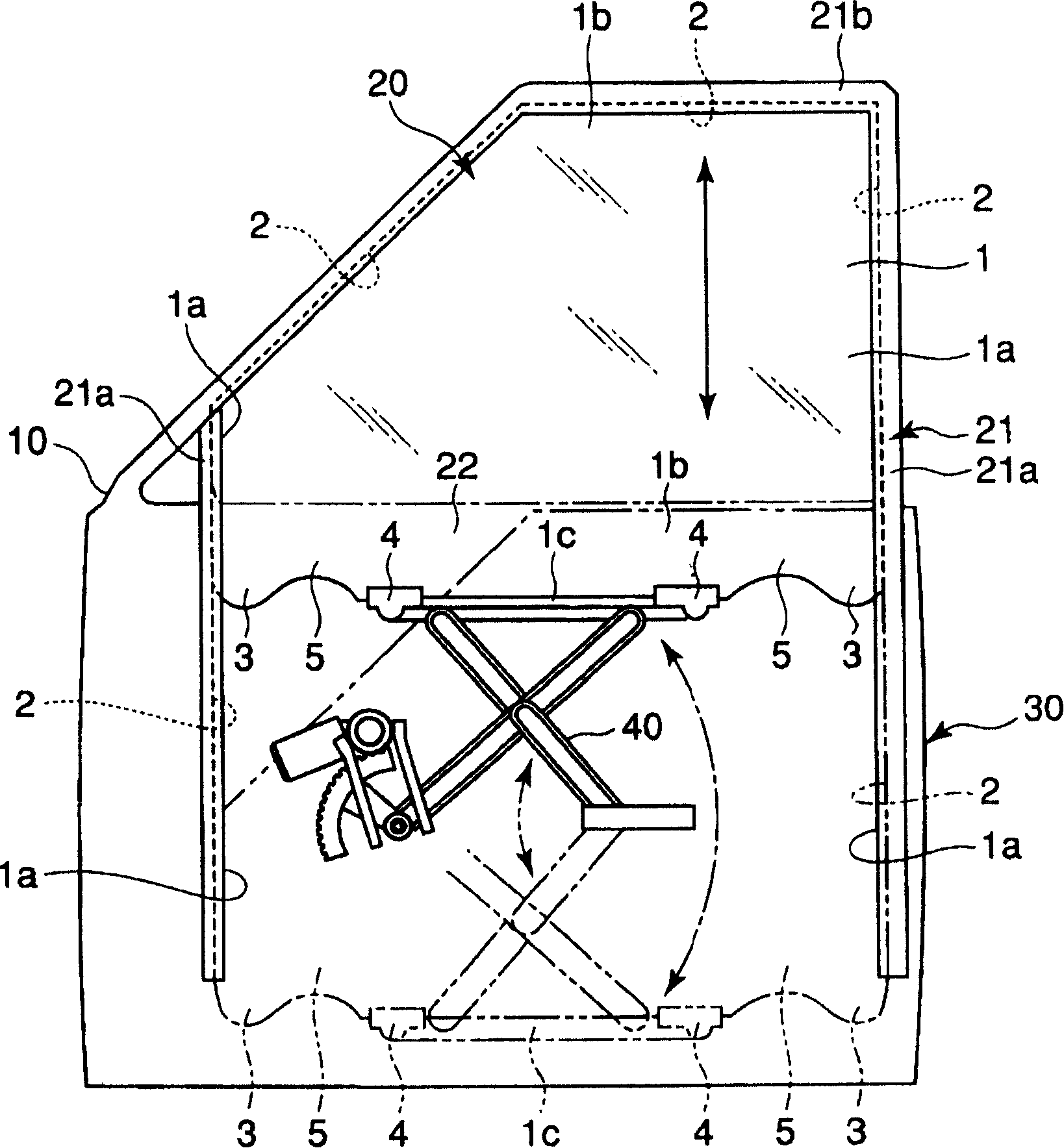

[0014] Below, take the lift glass 1 of the front door 10 of the automobile as an example, with reference to the figure 1 to attach Figure 4 The water drop induction structure of the lifting glass according to an embodiment of the present invention will be described in detail. Such as figure 1 As shown, the front door 10 has a window 20 formed in the upper half and a door panel 30 mounted in the lower half. On both side parts 21a and upper part 21b of the inner circumference of the window frame 21 corresponding to the frame of the window 20, a figure 2 Channel 2 shown. The water guide channel 2 installed along both side edge portions 1 a of the lift glass 1 extends to the inside of the front door 10 covered by the door panel 30 .

[0015] Such as figure 2 and image 3 As shown, a belt-shaped molding 23 is installed on the lower frame 22 on the outside of the vehicle window 20 . The top end 23a of the belt-shaped molding 23 is in frictional contact with the lift glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com