Nail and screw fixation system for improving the fixation of proximal fractures of the humerus

A technology of locking screws and screws, applied in the field of nails for improving the fixation of proximal humerus fractures, can solve problems such as undesired movement or dislocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

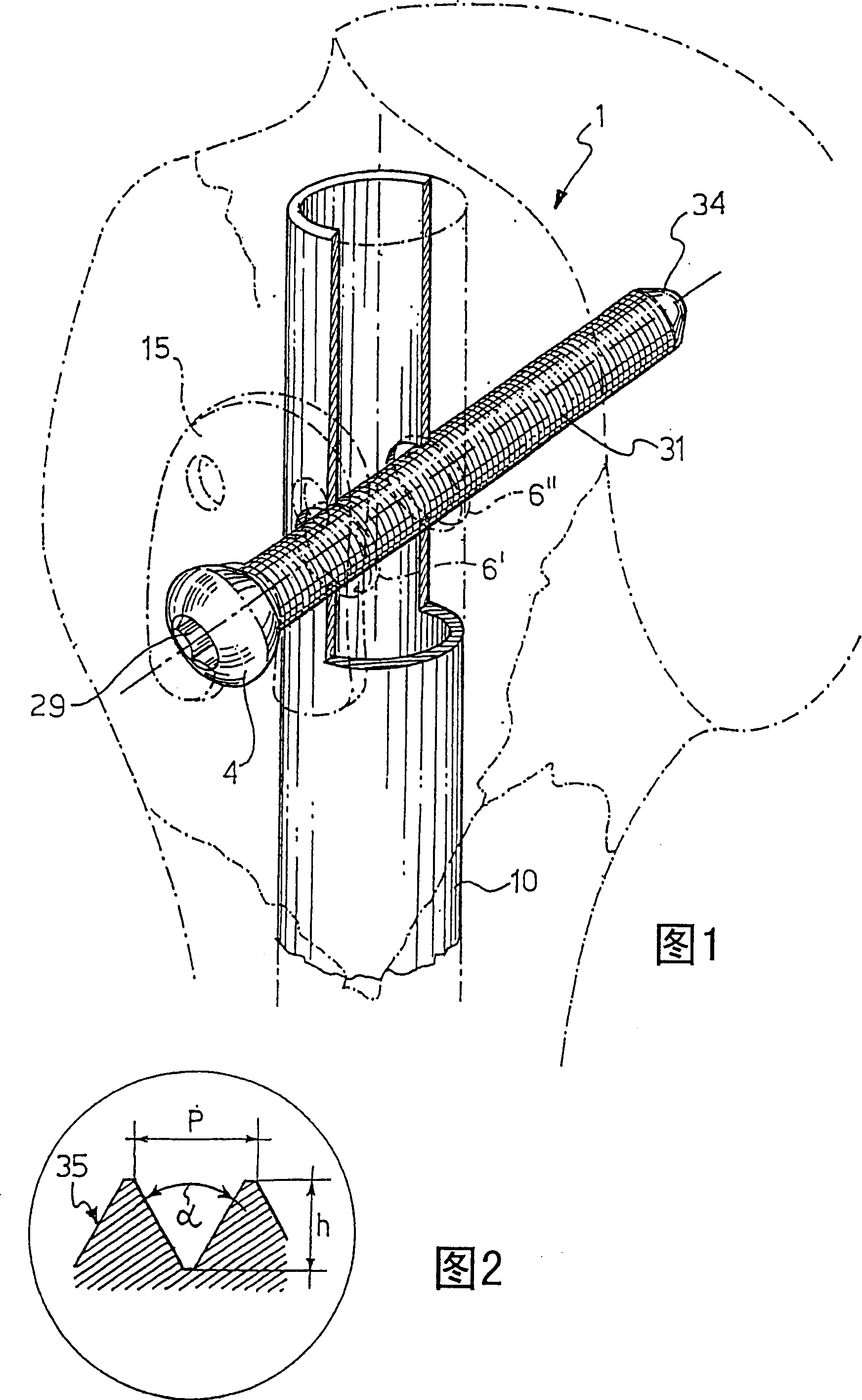

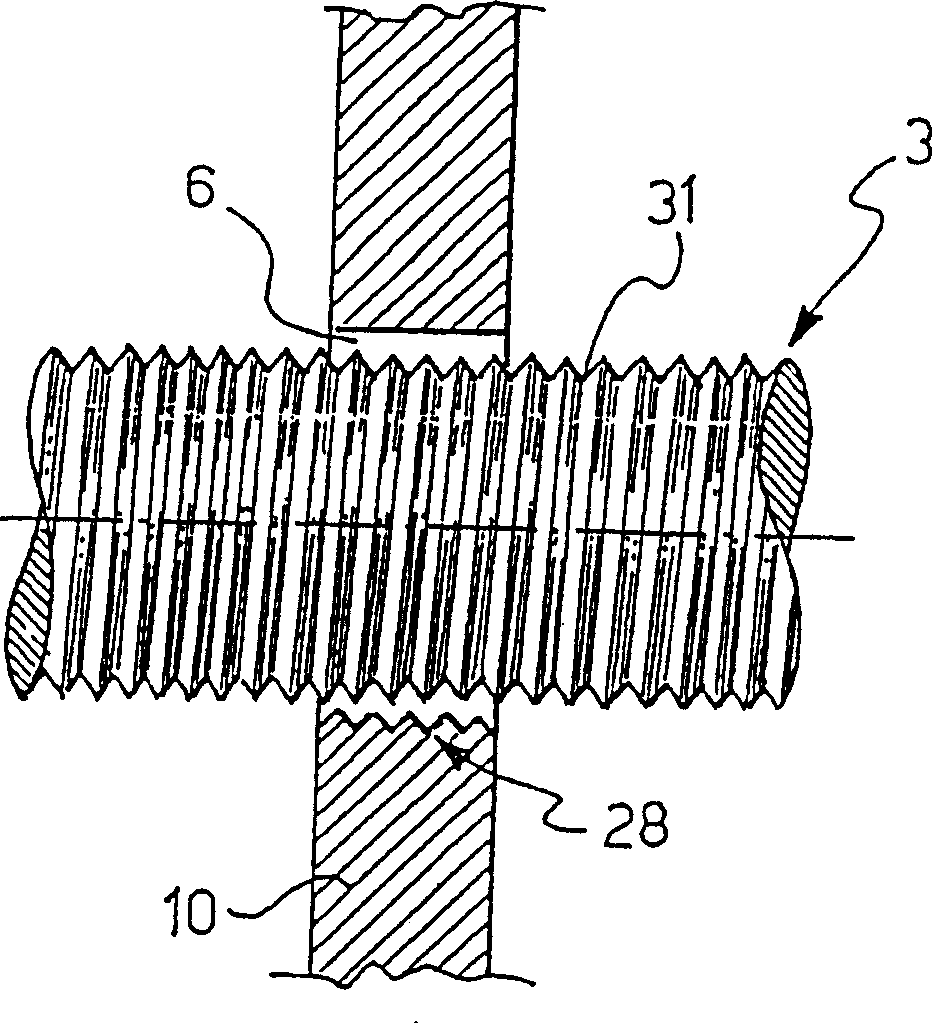

[0047] According to a first embodiment of the invention, the fixation system 1 comprises a humeral screw 10 and at least one proximal locking screw 3 .

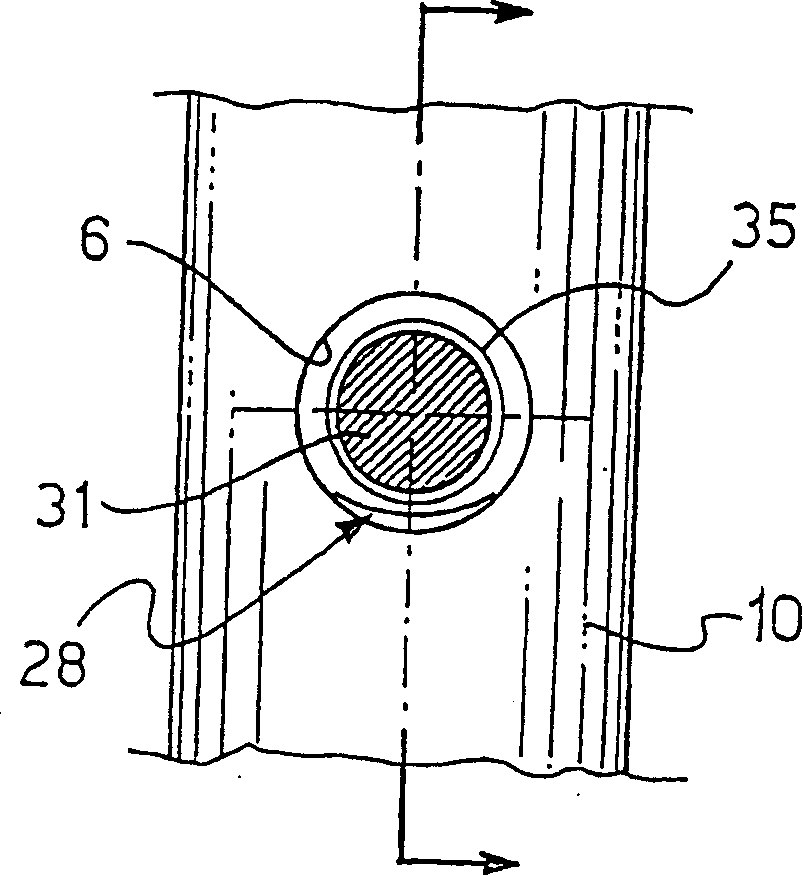

[0048] The humeral screw 10 may even comprise a set of proximal transverse holes for corresponding locking screws 3 . For example, in this embodiment at least 3 transverse holes 5 , 6 , 7 are shown in the proximal portion of the humeral screw 10 as shown in FIG. 7 .

[0049] More specifically, because the humeral screw 10 is hollow, each transverse hole 5, 6, 7 comprises a pair of holes realized in opposite walls of the screw and which can be aligned axially. For disclosure purposes, we treat these opposing holes as a single transverse hole.

[0050] Each transverse hole may be oriented at a selected angle relative to the longitudinal axis of the staple; however, at least two of the holes 5, 6 in the set of proximal holes lie on the same plane, while the third hole lies on a radial plane middle.

[0051] Advantageously, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com