Long stator motor

A motor and long stator technology, applied in the field of long stator motors, can solve the problems of increasing the current intensity, increasing the cross section of cables, and the inability to realize the layout of grooves, etc., and achieve the effect of large acceleration and high acceleration value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

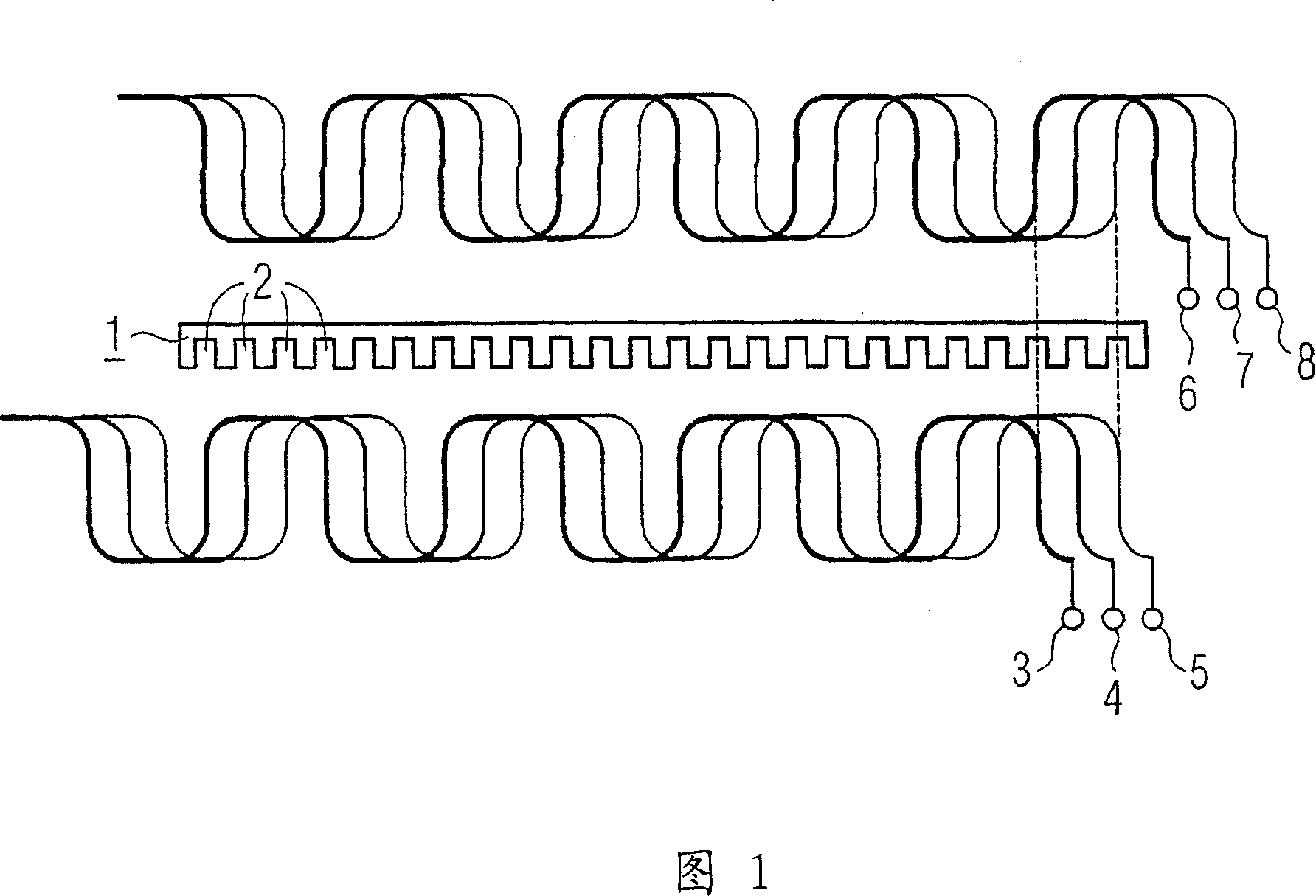

[0018] The stator core 1 shown in section has a sequence of grooves 2 . These grooves 2 serve to accommodate the cable windings 3 to 8 . It has hitherto been common to accommodate only three cable windings 3 to 5 of a three-phase AC system. The cable windings 3 to 5 each extend every second groove 2 so that the individual cable windings are evenly distributed.

[0019] In the case of a long stator motor according to an embodiment of the invention, three further cable windings 6 to 8 are laid in the same groove 2 . Here, the aforementioned cable windings 3 to 5 form a first layer, while the other cable windings 6 to 8 form a second layer. The grooves 2 do not have to be wider than in the known embodiments, but only deeper, which does not impair the stability of the stator core 1 . Wider grooves 2 are not possible for spatial reasons. The other cable windings 6 to 8 are laid relative to the previously mentioned cable windings 3 to 5 in such a way that in each groove 2 there ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com