Actuators with friction devices using wrap spring elements

A friction device and actuator technology, applied in the field of actuators, can solve the problems of increasing cost, difficulty in installation, inability to maintain position, etc., and achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

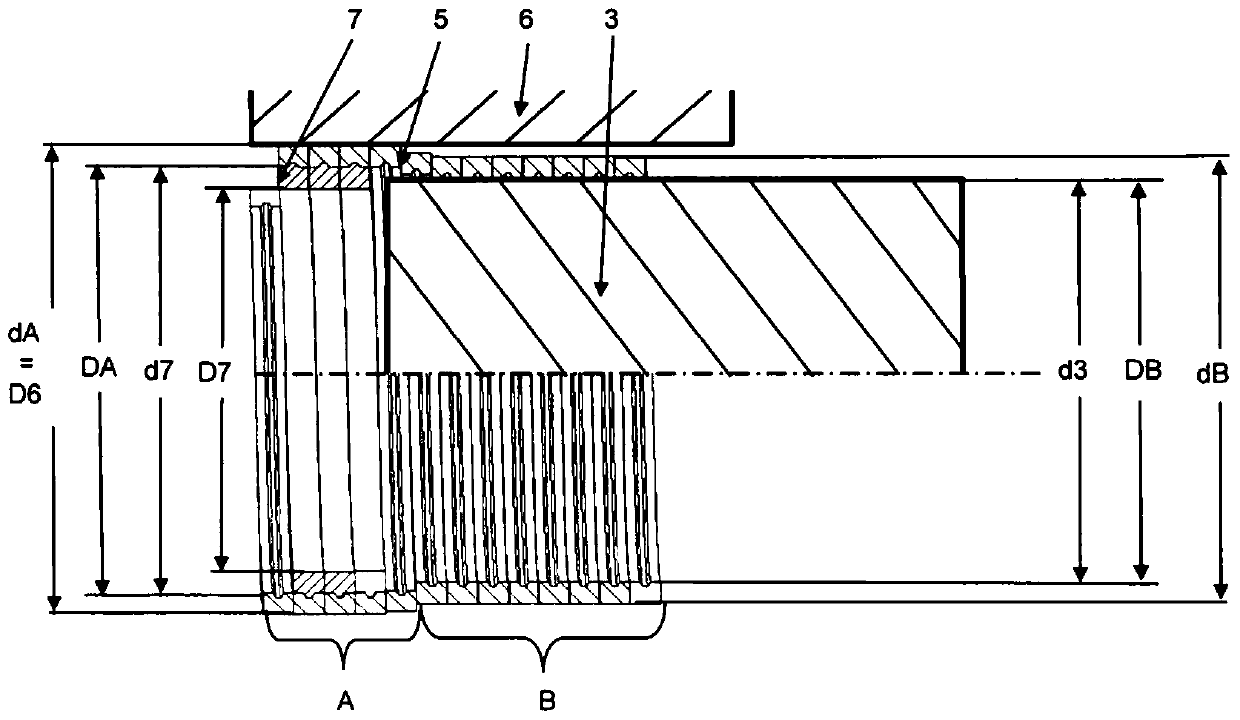

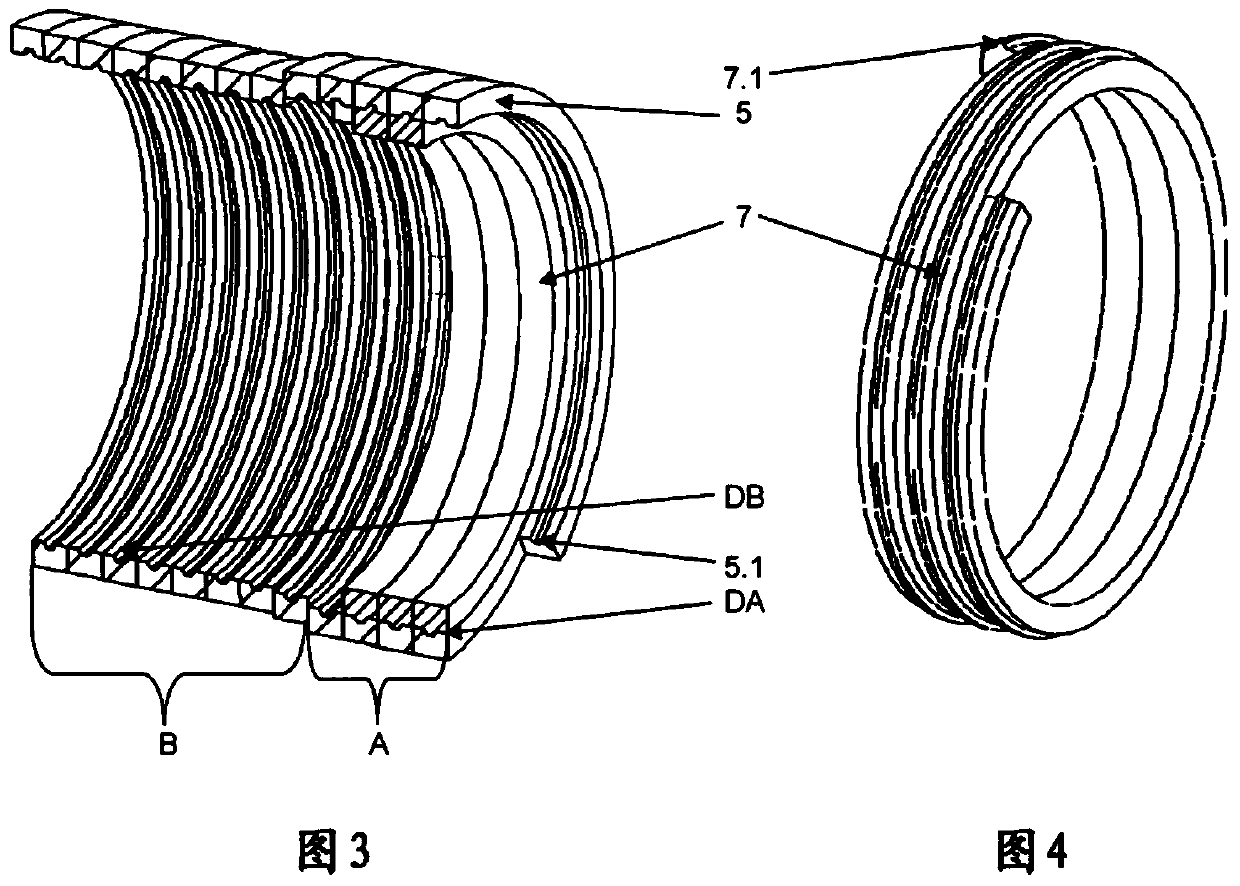

[0033] exist figure 1 shows an actuator according to the invention with a planetary roller screw drive (PWG) 1 having a screw 2 and a ring gear 3 between which planetary rollers 4 mesh. Ring gear 3 (sleeve) is operatively connected on its outer diameter, which acts as a shaft, to hub 6 by means of wrap spring elements 5 in the form of double wrap springs. figure 2 A schematic diagram of the ring gear 3 and the hub 6 is shown, between which the wrap spring element 5 is arranged.

[0034] according to figure 2 , the wrap spring element 5 has a first active area A with a contact area with the hub 6 and a second active area B with a contact area with the ring gear 3, wherein the first active area A with the outer diameter dA contacts The inner diameter D6 of the hub 6 is also non-positively connected with said inner diameter in the first rotational direction. The second active region B lies with its inner diameter DB on the outer diameter d3 of the ring gear 3 and surrounds it....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com