Flap optical fiber composite spinning preparation method

A composite spinning and optical fiber technology is applied in the field of composite spinning preparation of petal-shaped optical fibers to achieve the effect of avoiding joint loss

Inactive Publication Date: 2010-11-24

DONGHUA UNIV

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the composite spinning method has not yet been used to prepare petal-shaped optical fibers

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

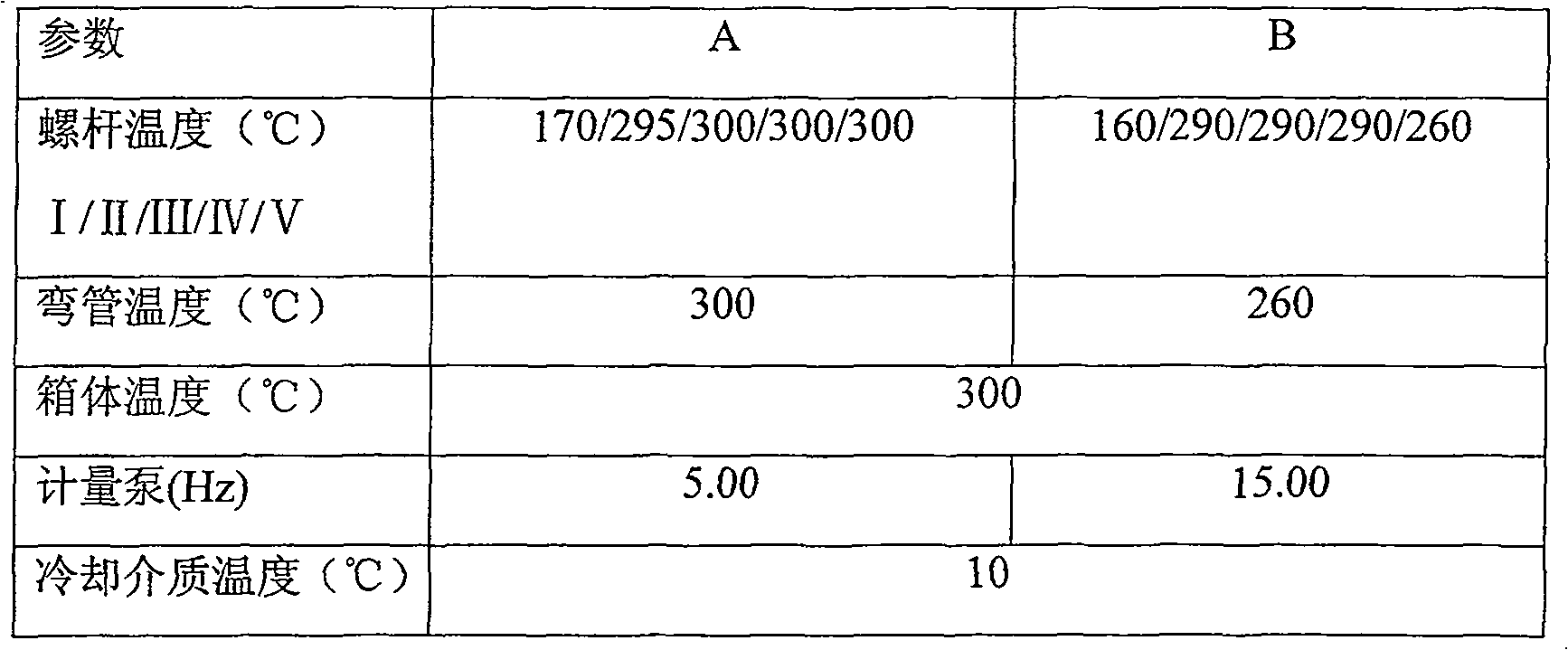

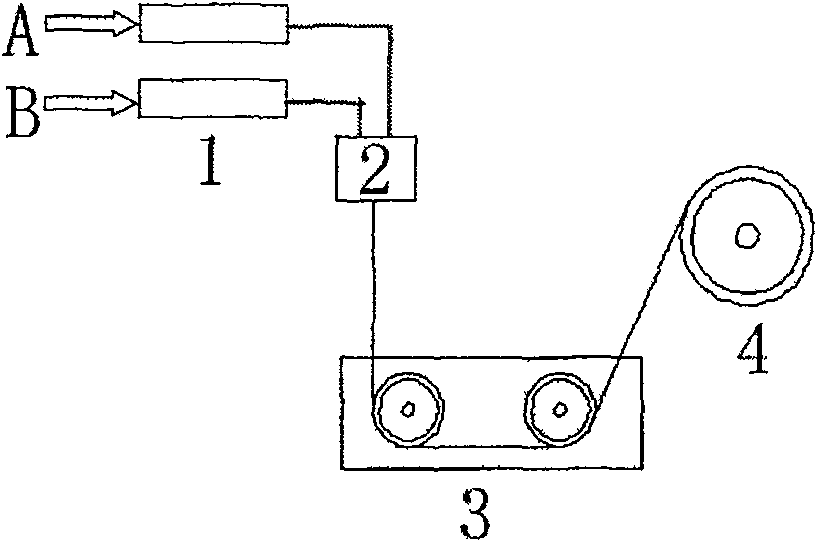

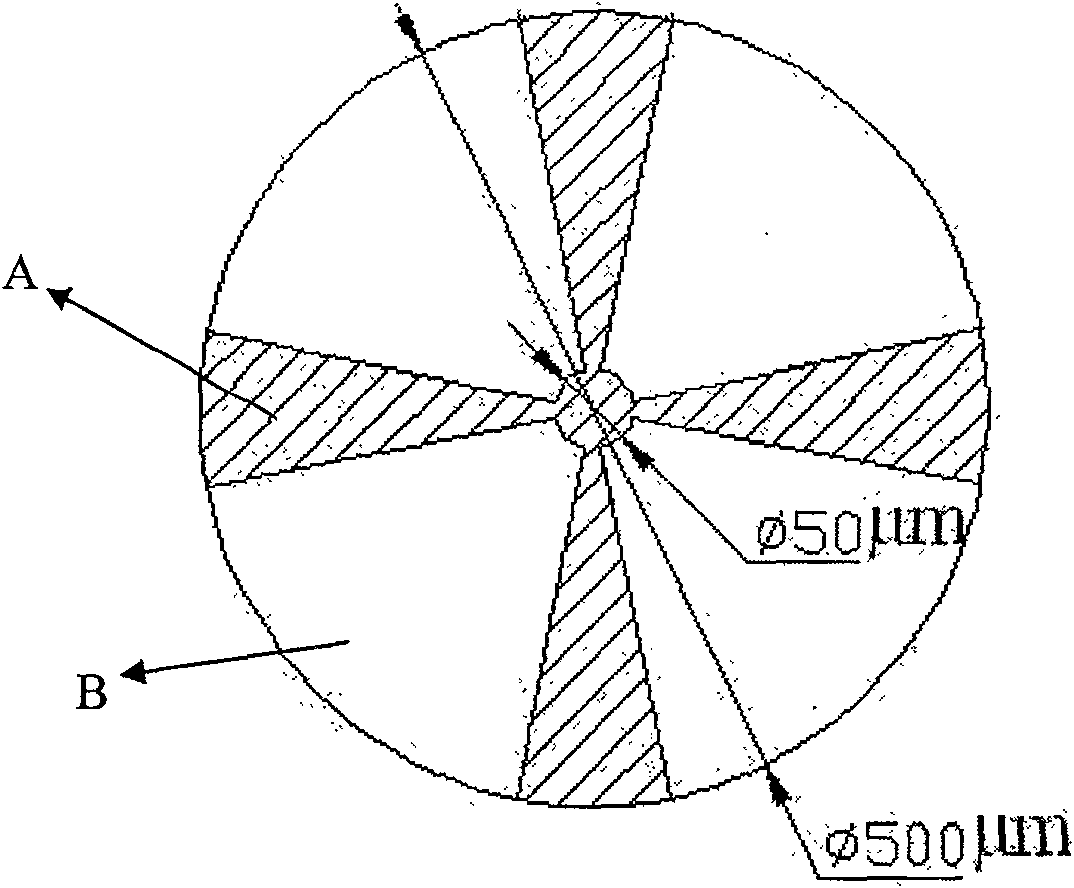

Login to View More Abstract

The invention relates to a process for preparing composite spinning of a valvular fiber, which comprises that high refractive index components are fed into a screw (A), low refractive index components are fed into a screw (B), the high refractive index components and the low refractive index components are respectively melted through the screws and reach to a same of spinning pack, spinneret holes commonly enter spinning guide holes, and a fiber is extruded, and then the fiber is cooled through a water bath cooling system and is winded. Sections of the two groups of components of the valvularfiber which is prepared by the invention are formed with a designed valvular fiber section shape, the two components mutually contact and are not separated, and the length of the obtained fiber is capable of being illimitably prolonged. The valvular fiber which is prepared by a composite spinning method is uniformly continuous, and the joint loss is avoided during connecting the fiber.

Description

A compound spinning preparation method of petal-shaped optical fiber technical field The invention relates to the field of optical fiber preparation and composite spinning, in particular to a composite spinning preparation method of a petal-shaped optical fiber. Background technique In 2001, KinSengChiang of the City University of Hong Kong proposed a petal-shaped optical fiber (Segmented Cladding Fiber, SCF, Figure 1) with a petal pattern distribution on the cross-section. "alternately. The leakage loss of the high-order mode in the petal-shaped fiber is large, while the loss of the fundamental mode is small, so that single-mode transmission can be realized. A.Yeung et al. disclosed the "Experimental demonstration of single-mode operation of large-coresegmented cladding fiber" in the "Optical Fiber Communication Conference (Optical Fiber Communication Conference)" in 2004. Introduced the preform-stretching method for reference to conventional silica optical fibers to pr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D01D5/28D01D10/00G02B6/00G02B1/00

Inventor 余木火段菊兰滕翠青韩克清袁象恺

Owner DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com