Piston type compressor and method of stepless regulating its transfer quantity

A stepless adjustment, compressor technology, applied in liquid variable capacity machinery, multi-stage pumps, mechanical equipment, etc., can solve the problems of small compressibility and complex structure, and achieve the effect of shortening the deflation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

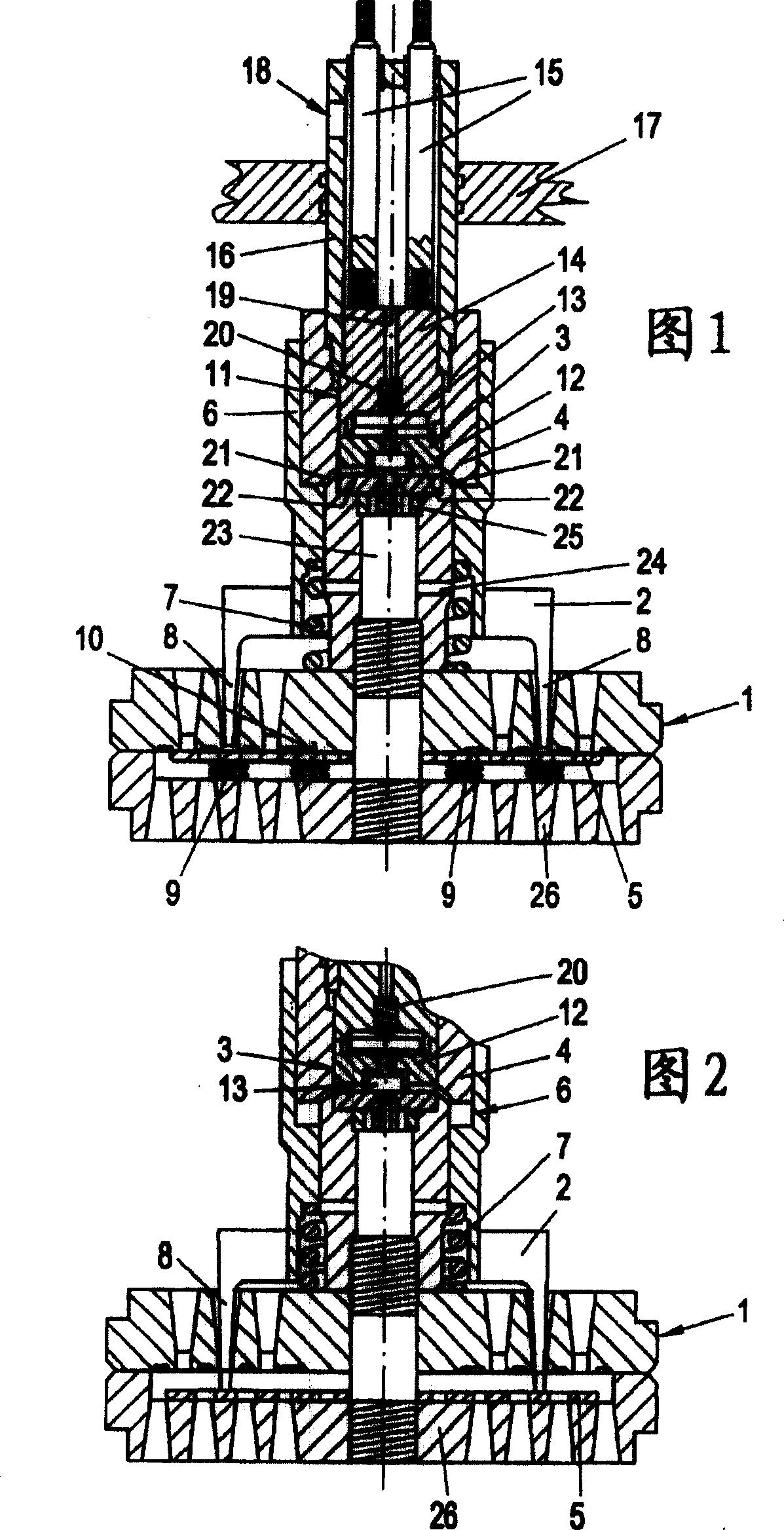

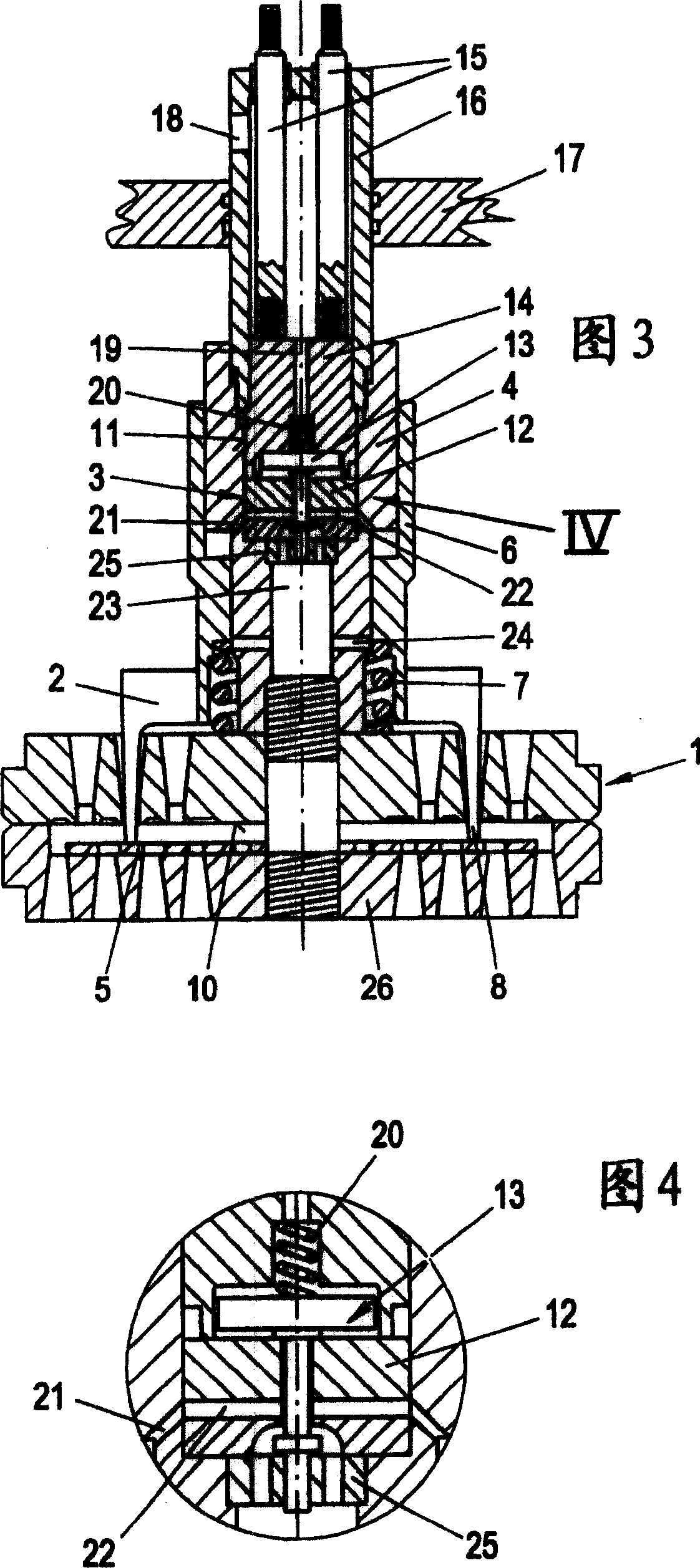

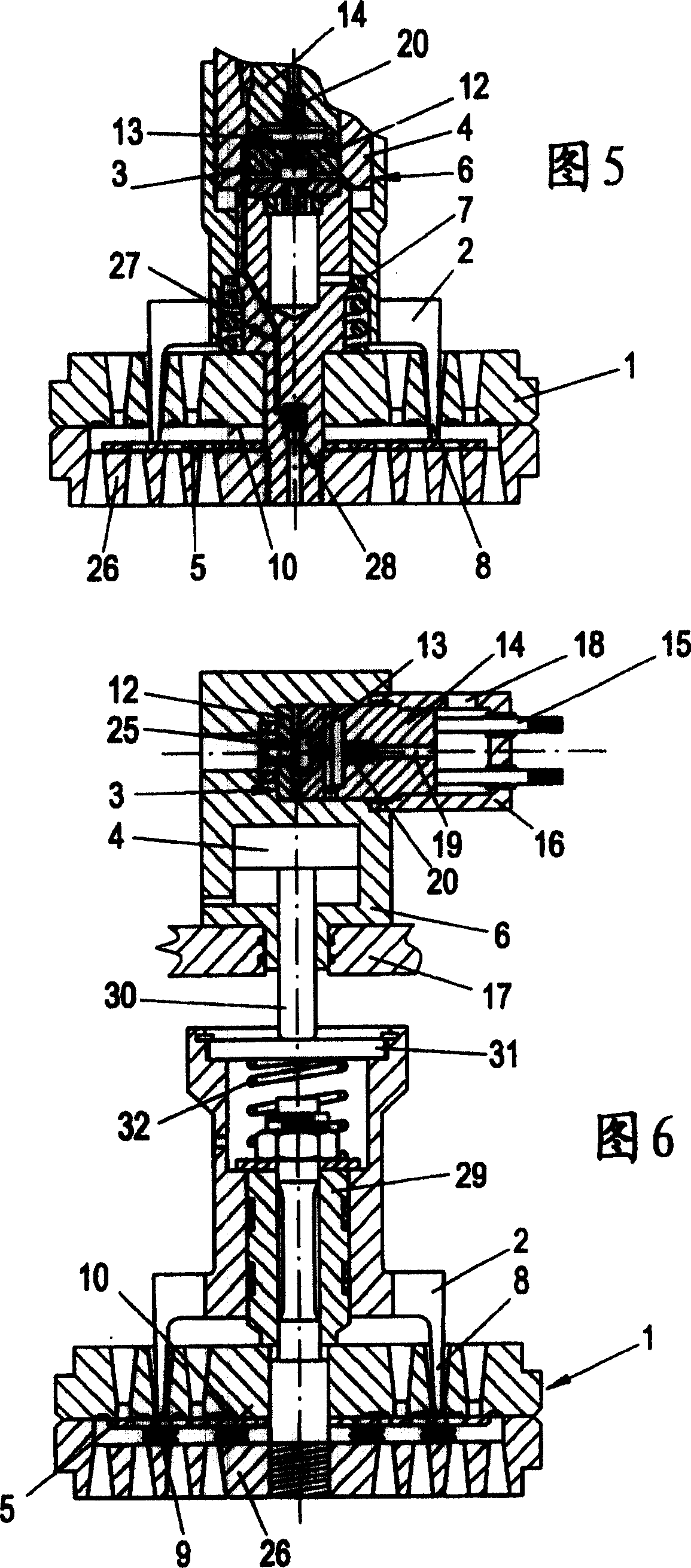

[0033] In all the embodiments according to FIGS. 1 to 6 , the suction valve 1 of the compressor is provided with a lifting claw 2 , which pushes at least one seal 5 of the suction valve 1 by means of a lifting piston 4 acted upon by gas pressure. It remains open in a part of the compressor's working stroke that can be controlled by means of a switchable control valve 3, through which the gas pressure loading is controlled, the lifting piston is located in the lifting cylinder, the gas pressure is applied to the lifting piston and the lifting between cylinders. Here the lifting piston 4 is at rest and fixed in the center of the suction valve 1 and thus forms with its outer circumference directly axially a guide for the lifting claw 2 or the lifting claw 2 forms the lifting cylinder 6 that moves axially therewith. Guide in sleeve-shaped upper part. The position shown in FIG. 1 is pressed into the upper end position by means of a helical spring 7, the lifting piston 4 rests on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com